Method for ion plating of graphite-like self-lubrication film on rigid gear for harmonic reducer

A harmonic reducer and self-lubricating film technology, applied in the field of material manufacturing, can solve the problems of wear and damage between the friction pairs of the harmonic reducer gear, insufficient durability, etc., to improve market competitiveness, reduce friction coefficient, and improve hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

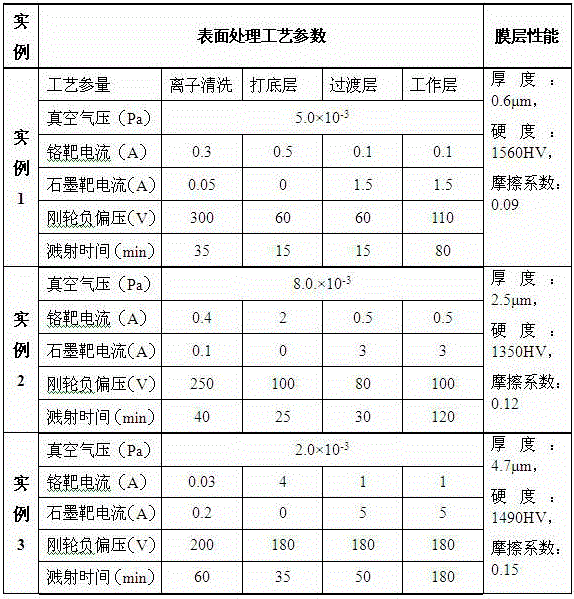

Examples

Embodiment Construction

[0015] The specific implementation is as follows:

[0016] A method for ion-plating a graphite-like self-lubricating film layer on a rigid wheel for a harmonic reducer, comprising the steps of:

[0017] Step 1. First, carry out ultrasonic dewaxing and degreasing cleaning on the steel wheel to be plated. After blowing dry with a compressed air dryer, put the steel wheel into the vacuum chamber of the four-target micro-arc ion plating equipment. There are chromium targets and pure graphite targets, and the vacuum chamber is evacuated so that the vacuum degree of the vacuum chamber is less than 6.0×10 -3 Pa, and argon gas is passed into the vacuum chamber, the gas flow rate is 7sccm~100sccm, and the working pressure in the vacuum chamber is kept at 1.0×10 -3 Pa~8.0×10 -3 ;

[0018] Step 2. Carry out ion bombardment cleaning to the steel wheel in the vacuum chamber of step 1, and keep the working air pressure in the vacuum chamber at 1.0×10 -3 Pa~8.0×10 -3 , the control param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com