Transfer and positioning device and method for pole pieces of wound laminated batteries

A battery pole piece and positioning device technology, which is applied in the direction of secondary battery, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of inaccurate positioning and transfer pole piece position, and achieve the effect of improving production efficiency and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

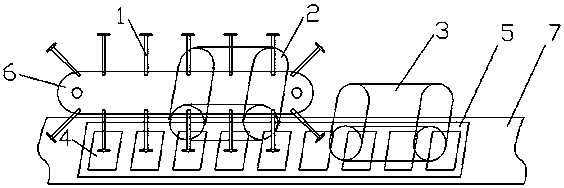

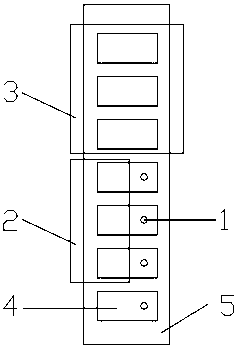

[0014] See attached figure 1 , 2 shown. The present invention is achieved through the following technical solutions: the transfer and positioning device for the winding-type laminated battery pole piece includes a conveying device 7 for carrying and conveying the processing of the battery pole piece 4, and a heat compounding device is arranged above the conveying device 7 , An adsorption device for adsorbing and fixing the battery pole piece to be processed is arranged above the conveying device 7, and the adsorption device is a plurality of vacuum chucks 1. The thermal compounding device includes a semi-thermal compounding device 2 and a full-thermal compounding device 3, which are arranged successively according to the direction of the conveying device 5; multiple vacuum chucks 1 are located on one side of the semi-thermal compounding device 2. The plurality of vacuum chucks 1 and the semi-thermal composite device 2 are not in a longitudinal plane. A plurality of vacuum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com