Automobile air conditioning liquid filling equipment and filling method thereof

A filling equipment, automotive air-conditioning technology, applied in lighting and heating equipment, heating methods, refrigeration and liquefaction, etc., can solve the problems of equipment failure maintenance costs, high prices, shift changes, etc., to reduce failure maintenance costs and strengthen self Preventive measures to improve the effect of equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

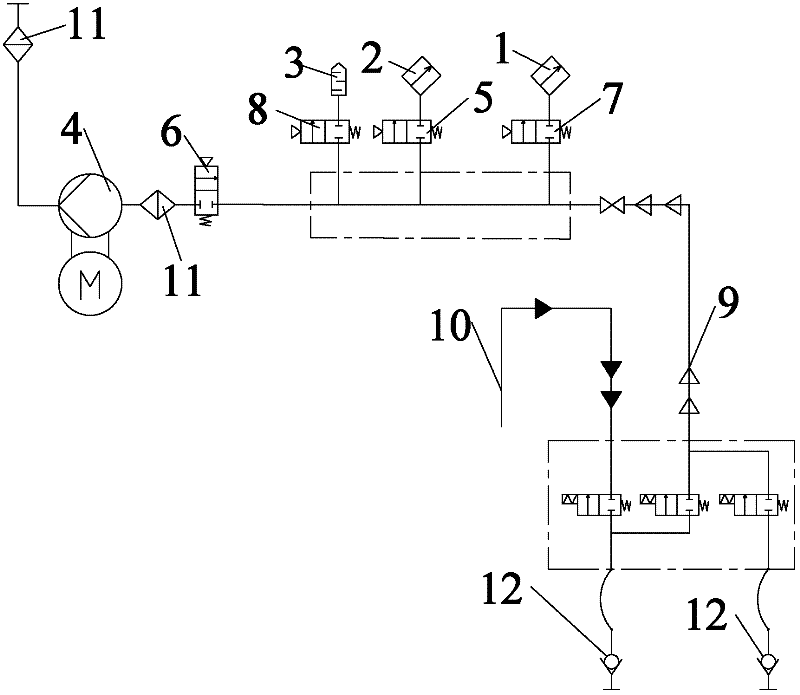

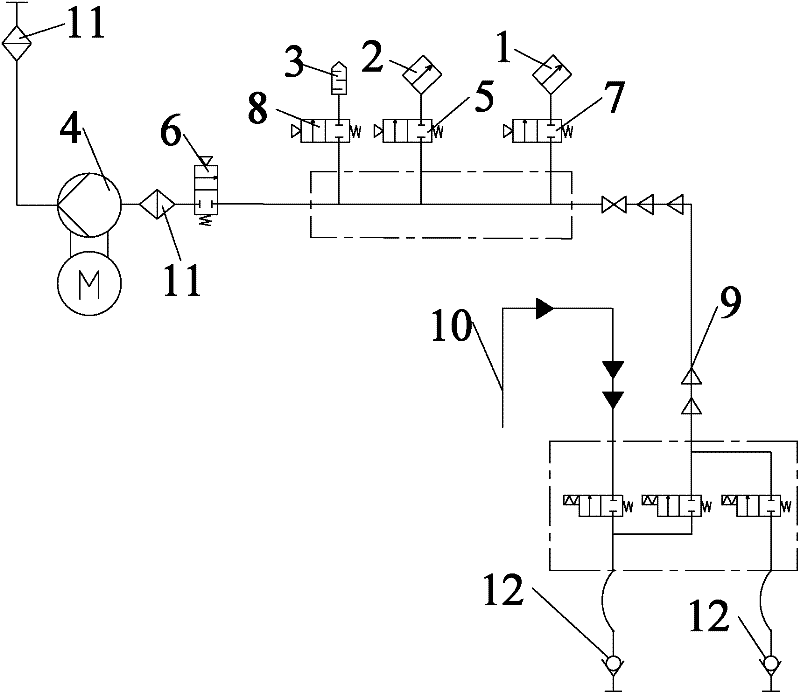

[0020] Such as figure 1 As shown, on the basis of the filling equipment with the above structure, the pressure sensor 1 communicates with the vacuum detection pipeline 9 through another branch pipeline, and the third control valve 7 controlled by the control system is arranged in the branch pipeline. The control system controls the on-off between the pressure sensor 1 and the vacuum detection pipeline 9 through the third control valve 7. When the operator connects the filling equipment and the automobile air-conditioning fluid pipeline, the control system controls the third control valve 7 to be connected. After the filling of the air-conditioning fluid is completed, the control system can control the third control valve 7 to be disconnected, so as to avoid the influence of the pressure sensor 1 when the vacuum sensor 2 detects the negative pressure of the vacuum detection pipeline 9 .

Embodiment 2

[0022] Such as figure 1 As shown, a muffler 3 is provided in the vacuum detection pipeline 9, and the muffler 3 communicates with the vacuum detection pipeline 9 through a third branch pipeline, and a fourth control valve controlled by the control system is arranged in the third branch pipeline. 8. The muffler 3 and the fourth control valve 8 are used to release impurities in the vacuum detection pipeline 9 and reduce noise; when the air-conditioning fluid is filled, the operator disconnects the quick-plug connector 12 of the filling equipment from the automobile air-conditioning pipeline connection, open the fourth control valve 8 to release the positive pressure inside the vacuum detection pipeline 9, and prepare for the next filling. The technical content of this embodiment is applicable to the filling equipment with any structure mentioned above.

Embodiment 3

[0024] The first control valve 5 and the second control valve 6 can optionally be controlled on and off by the control system, so as to improve the automation of the filling equipment. The technical content of this embodiment is applicable to the filling equipment with any structure mentioned above.

[0025] In addition, the present invention also discloses a filling method for the above-mentioned automobile air-conditioning liquid filling equipment, and the steps of the filling method are as follows:

[0026] When the operator connects the filling equipment and the automobile air-conditioning fluid pipeline, the control system first controls the first control valve 5 to be disconnected, the second control valve 6 to be disconnected, and the first control valve 5 to disconnect the vacuum sensor 2 from the filling equipment. The connection between the vacuum detection pipeline 9, the second control valve 6 disconnects the connection between the vacuum pump 4 and the vacuum dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com