Method for preparing three-dimensional nano space electrode by adopting self-alignment forming

A three-dimensional nano, self-aligned technology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problem of shortage of three-dimensional nanostructure electrode preparation methods, and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

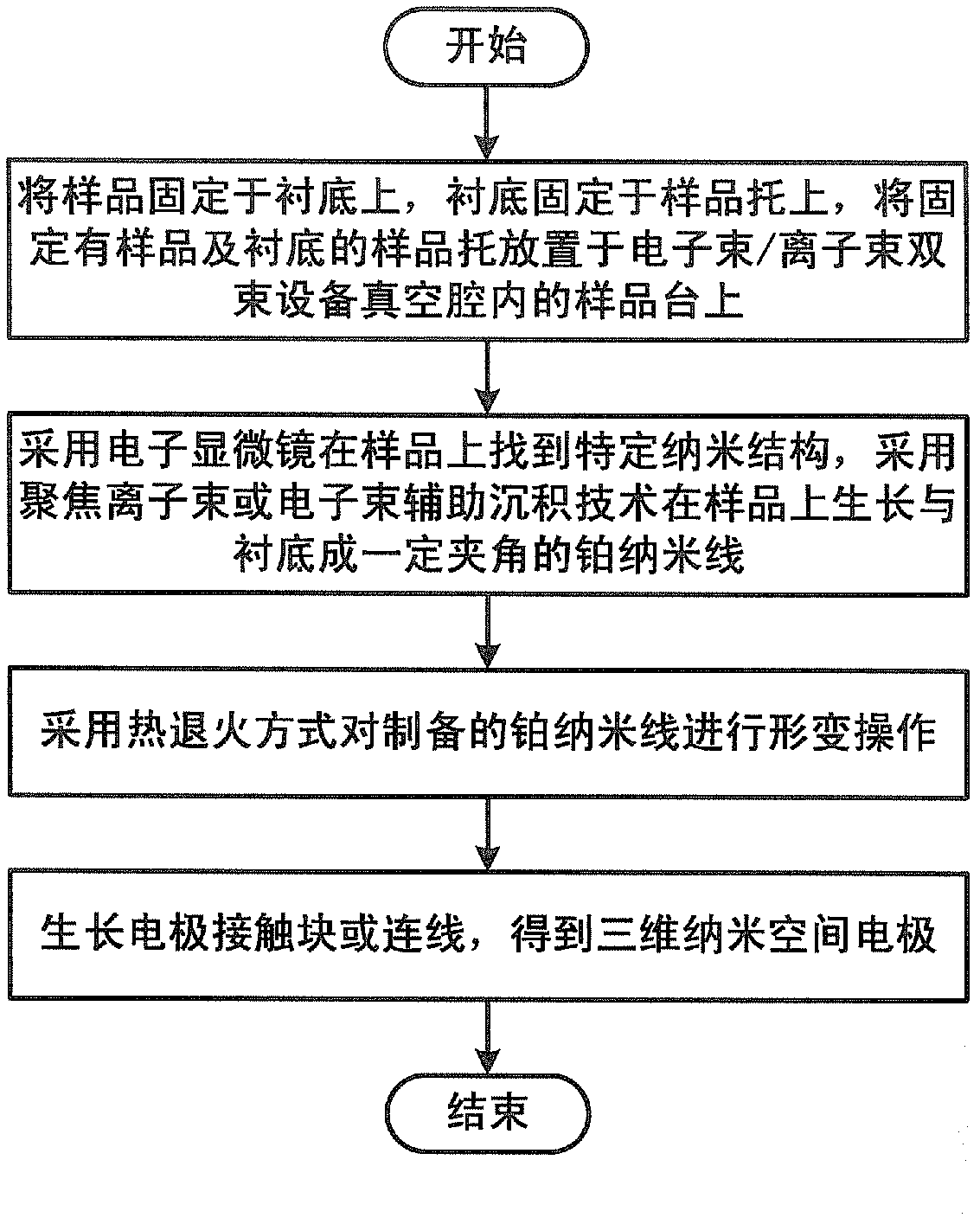

[0037] Such as figure 1 as shown, figure 1 It is a flow chart of a method for preparing a three-dimensional nano-space electrode by self-alignment molding provided by the present invention, and the method includes the following steps:

[0038] Step 1: Fix the sample on the substrate, fix the substrate on the sample holder, and place the sample holder with the sample and substrate fixed on the sample stage in the vacuum chamber of the electron beam / ion beam dual beam equipment;

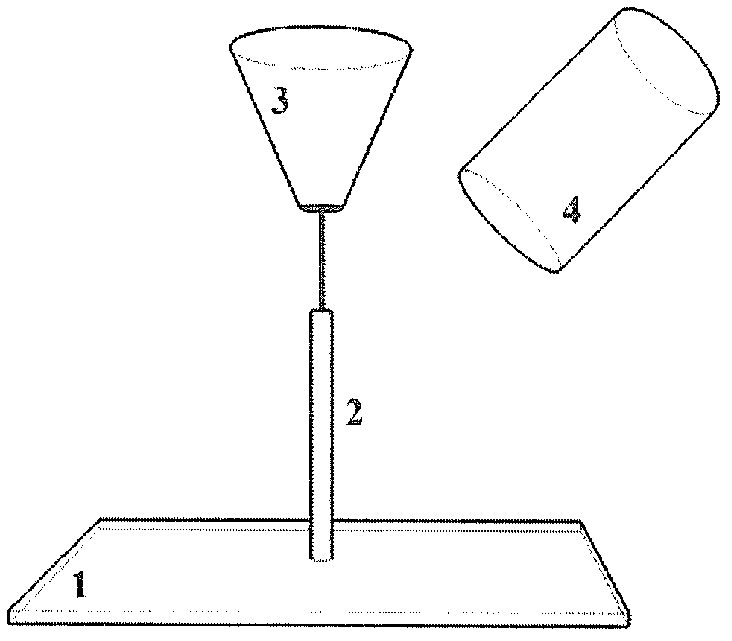

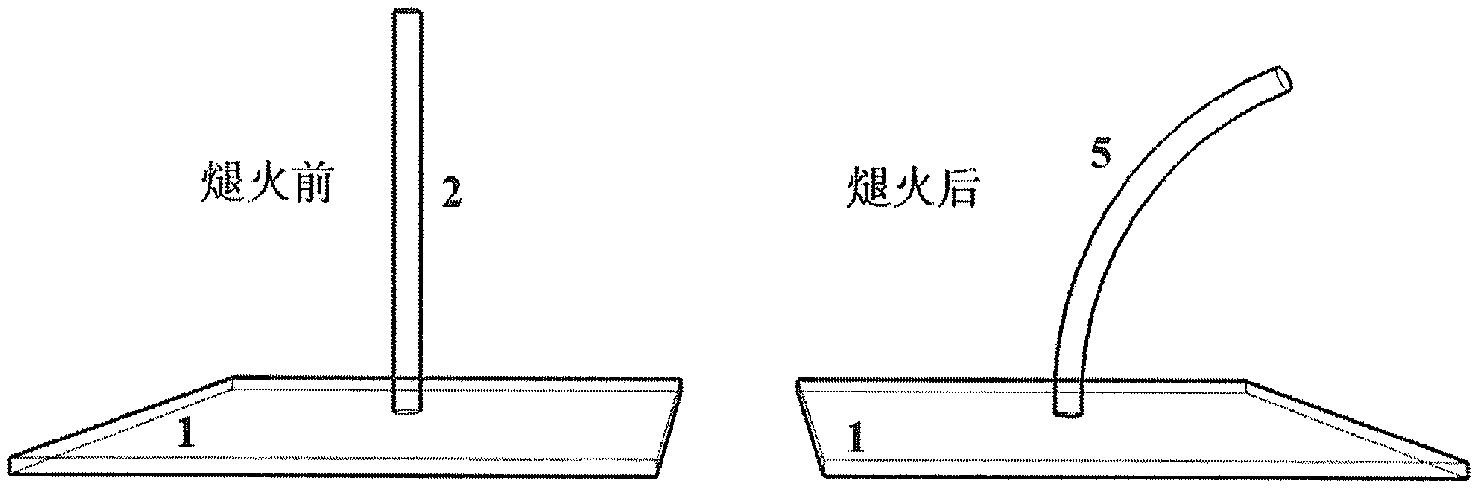

[0039] Step 2: Use an electron microscope to find a specific nanostructure on the sample, and then use focused ion beam or electron beam assisted deposition technology to grow platinum nanowires on the sample that form a certain angle with the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com