Large double-layer thin-wall D-type section vacuum chamber window assembly welding positioning device

A vacuum chamber and window technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult vibration problems, difficult window sealing surface and window position size tolerances, etc., to improve welding efficiency and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

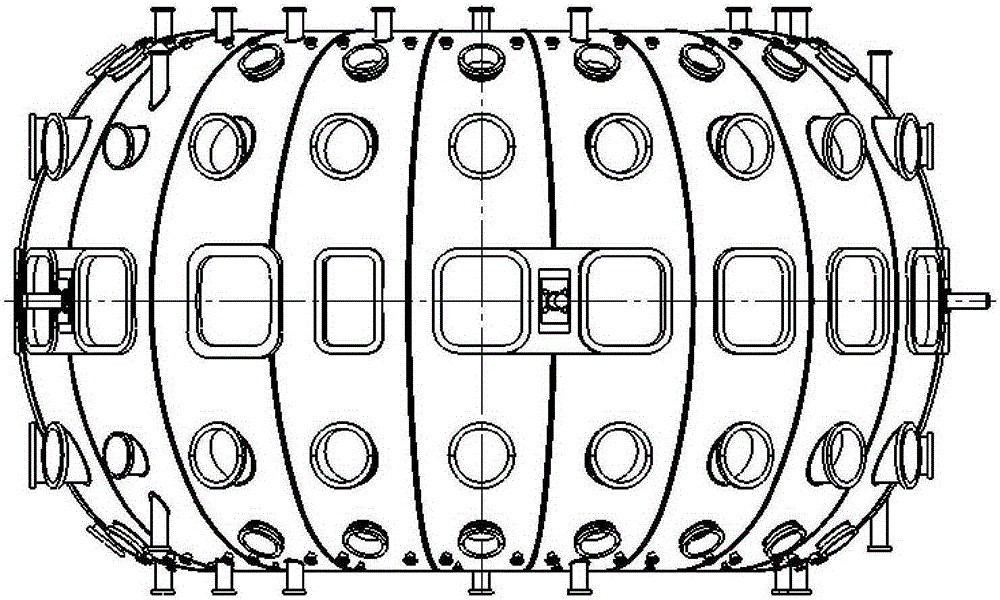

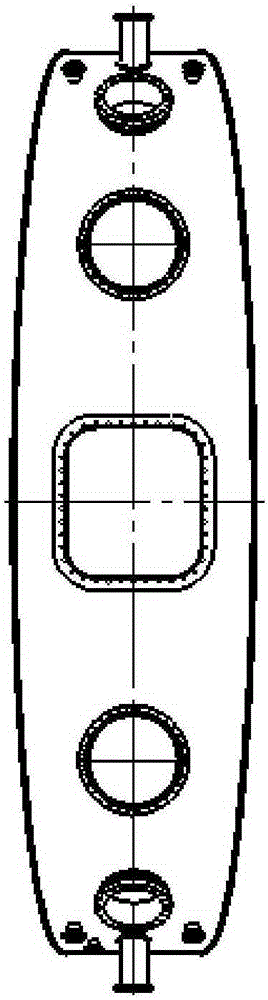

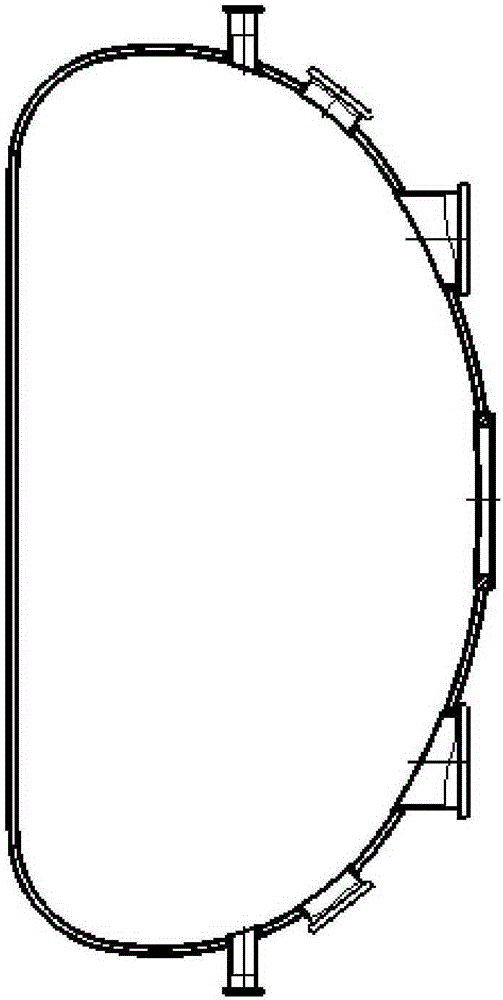

[0026] A large-scale double-layer thin-walled D-shaped section vacuum chamber window assembly welding positioning device, the structure of the large double-layer thin-walled D-shaped section vacuum chamber is a double-layer thin-walled fully welded ring structure with a D-shaped section, and the vacuum chamber consists of 20 Each sector is assembled and welded, and 5-7 of the following 7 windows are opened on each sector according to the vacuum chamber structure setting: the center line of the equipment is on the same line as the center line of the straight segment in the D-shaped section sector. On a straight line, the central axes of the two opposite windows are coaxial and parallel to the central line of the equipment, the central axis of the mid-plane window is perpendicular to the central line of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com