Large pulse power supply heating welding method for Ti-6Al-4V titanium alloy

A welding method, ti-6al-4v technology, applied in the direction of high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of long welding time, large one-time investment of welding machine, high operating cost, etc., and achieve welding The effect of large part size, great application value, and economical preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

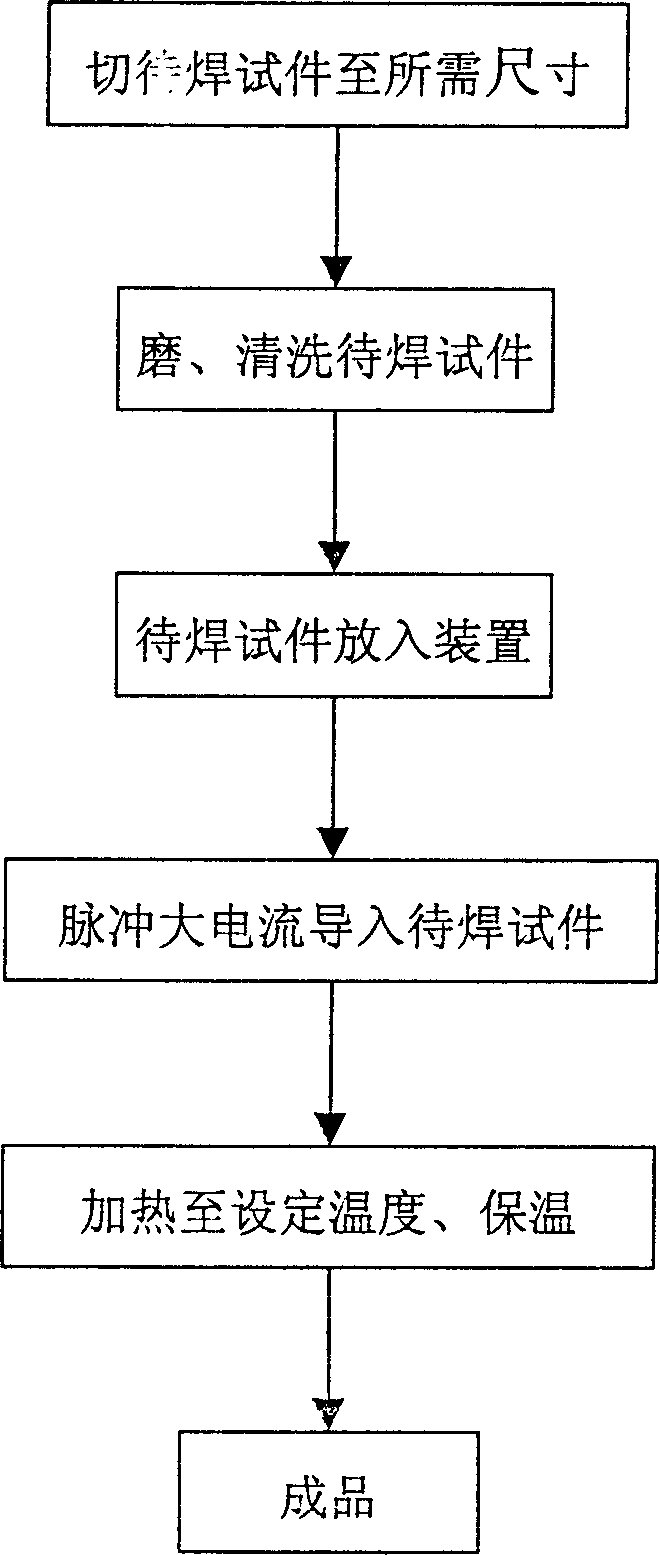

Method used

Image

Examples

Embodiment 1

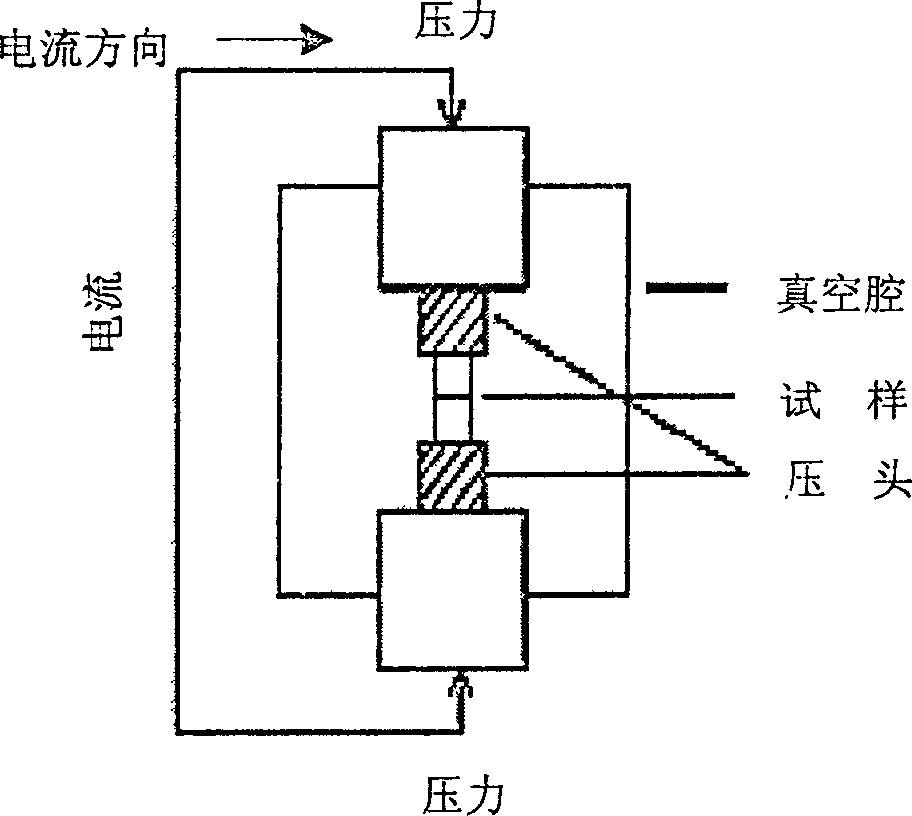

[0017] Example 1: Take two Ti-6Al-4V titanium alloy blocks with a size of φ20mm×15mm, process the surface to be welded to be relatively flat, and put them into a pulse high-current heating device. First vacuumize the cavity of the device to 4Pa, and then pass high-purity Ar into the cavity for protection. The welding temperature is 700°C, the holding time is 5min, and the pressure is 5MPa. There is a certain thickness of diffusion transition layer at the interface of the obtained weldment, the tensile strength is greater than the strength value of the base metal, and the fracture occurs in the matrix.

Embodiment 2

[0018] Example 2: Take two Ti-6Al-4V titanium alloy blocks with a size of φ20mm×15mm, process the surface to be welded to be relatively flat, and put them into a pulse high-current heating device. First vacuumize the cavity of the device to 5Pa, and then pass high-purity Ar into the cavity for protection. The welding temperature is 650°C, the holding time is 10min, and the pressure is 5MPa. There is a diffusion transition layer with a certain thickness at the interface of the obtained welded part, and the tensile strength is above 900 MPa.

Embodiment 3

[0019] Example 3: Take two Ti-6Al-4V titanium alloy blocks with a size of φ20mm×15mm, process the surface to be welded to be relatively flat, and put them into a pulse high-current heating device. First vacuumize the cavity of the device to 6Pa, and then pass high-purity Ar into the cavity for protection. The welding temperature is 600°C, the holding time is 15min, and the pressure is 5MPa. There is a certain thickness of diffusion transition layer at the interface of the obtained weldment, the tensile strength is greater than the strength value of the base metal, and the fracture occurs in the matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com