Steam exhausting cooling method and device of condensing steam turbine of auxiliary thermal power station

A cooling device and steam turbine technology, applied in steam engine devices, mechanical equipment, engine components, etc., can solve the problems of high standard coal consumption, land occupation and noise, and high one-time investment in power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

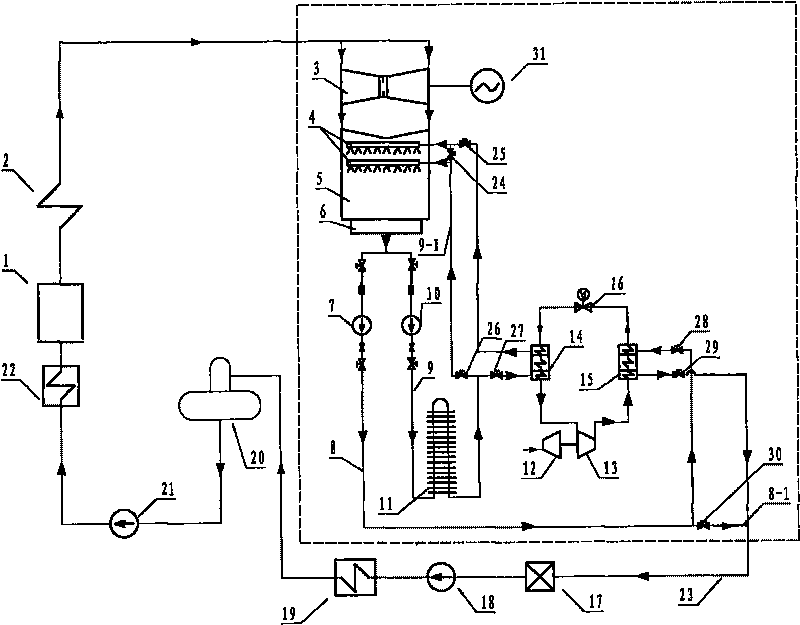

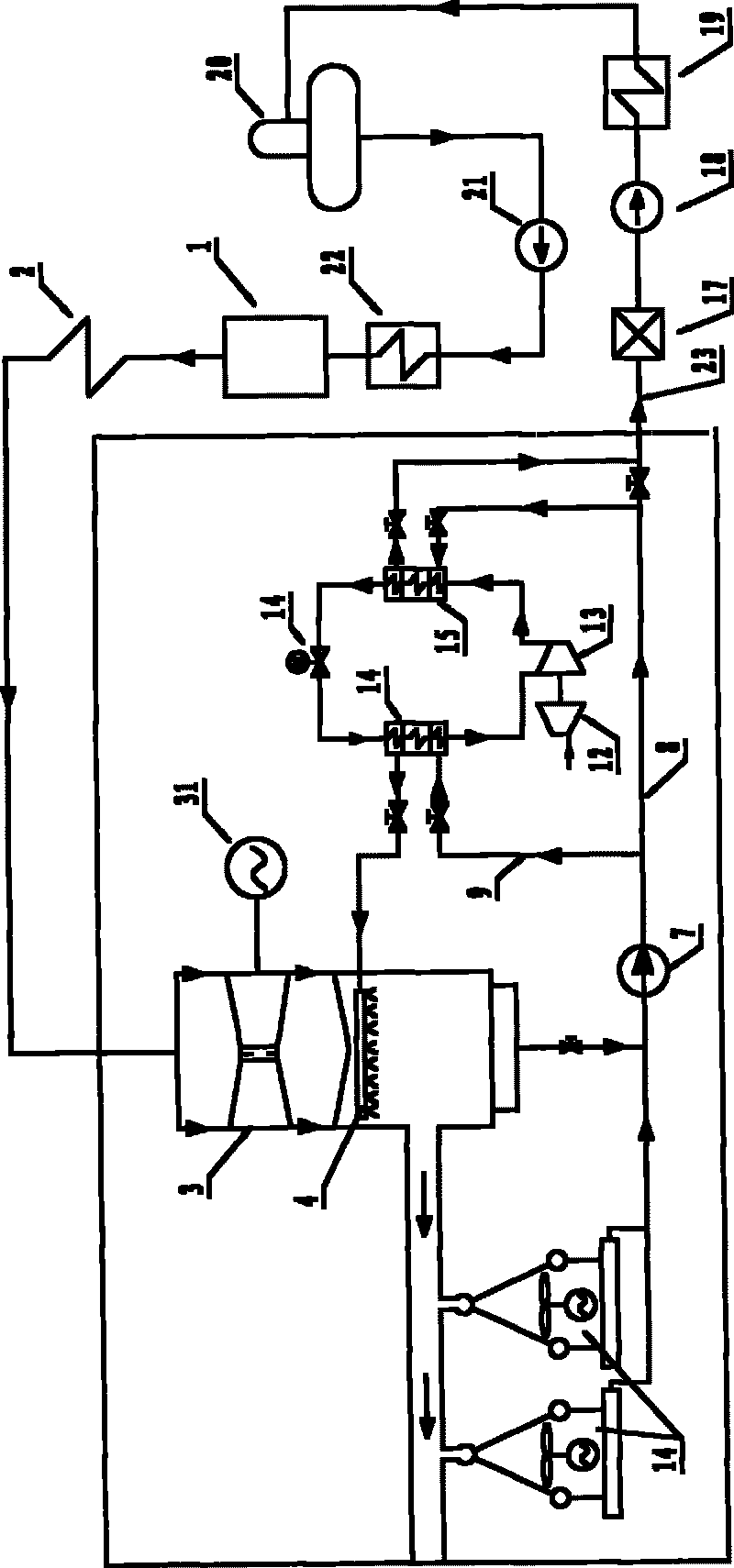

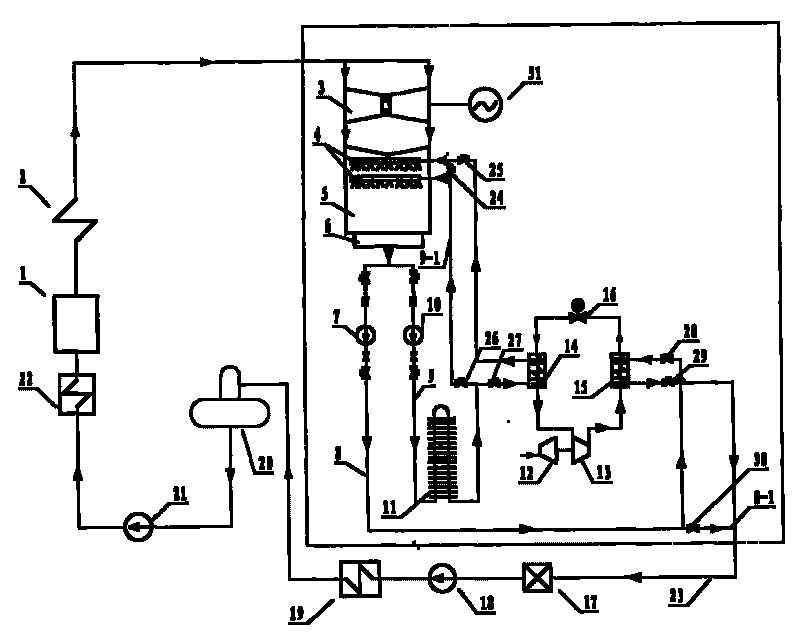

[0013] The present invention adopts the mixed cooling method for the exhaust steam of the condensing steam turbine in the thermal power station. The condensed water in the hot well of the condenser is divided into two paths, and one path enters the air-cooled heat exchanger and the evaporator of the refrigeration equipment to cool down in turn, and then the condenser sprays water The mechanism sprays into the condenser and mixes with the exhaust steam of the steam turbine to transfer heat, absorb the condensation heat of the steam turbine exhaust, and maintain the vacuum of the condensing equipment; the other path passes through the condenser of the refrigeration equipment, absorbs the heat released by the condenser, and enters the low pressure after the temperature rises The heater realizes heat transfer, reduces heat loss and improves thermal economy. The refrigerating equipment is powered by a small steam turbine driven by steam or is an absorption refrigerating machine, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com