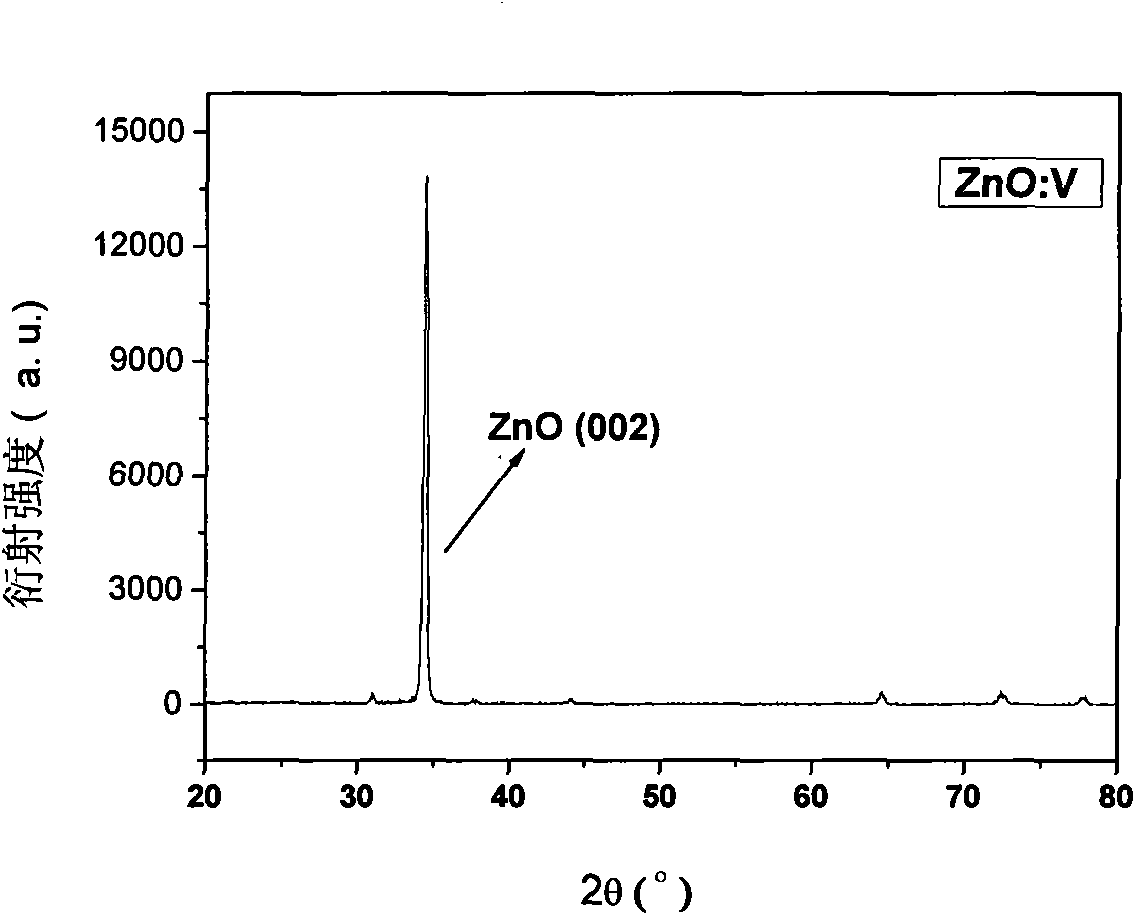

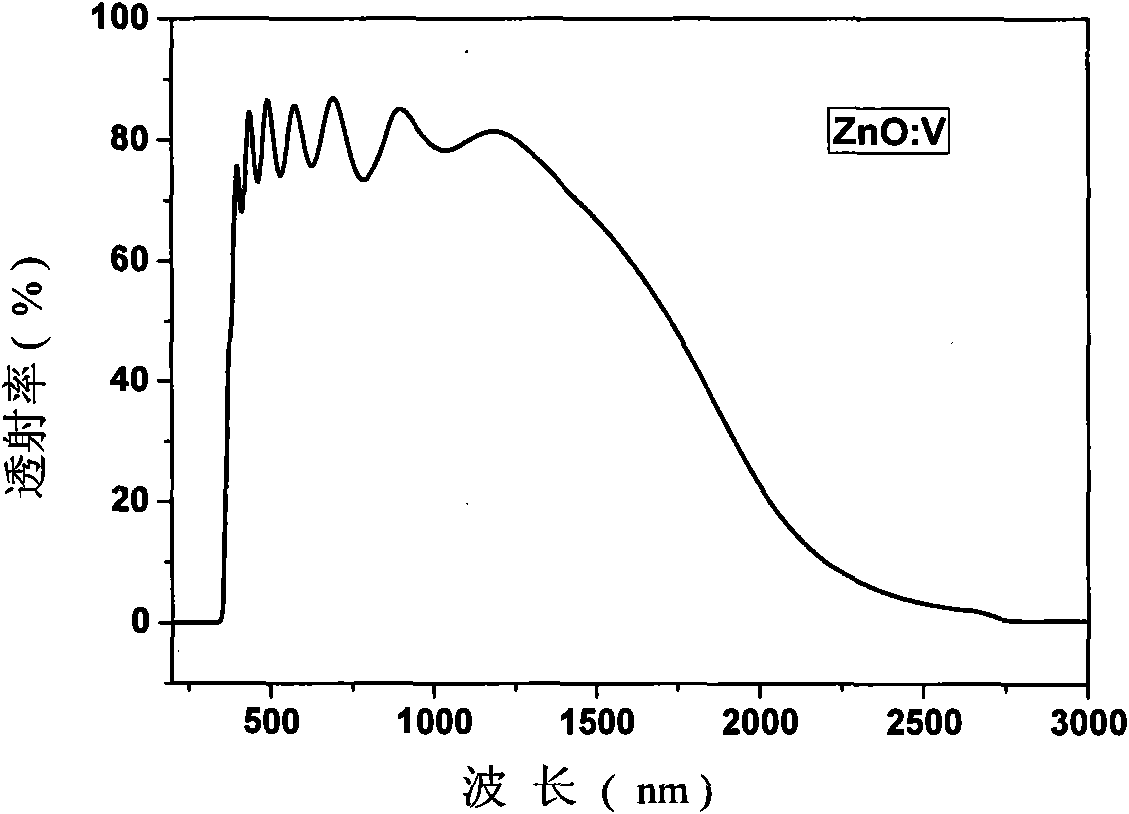

Low-temperature manufacturing method and special target of ZnO transparent conductive film

A transparent conductive film, zinc oxide technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of reducing near-infrared band transmittance, reducing film mobility, increasing free carrier absorption, etc. It can reduce the scattering of ionized impurities, be beneficial to large-scale production and popularization and application, and improve the electron mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Special target material of the present invention: ZnO: V target is installed on the target gun of magnetron sputtering equipment, and the atomic percentage of V / (V+Zn) in the target material is 1.79%, with Corning glass as substrate, substrate After being ultrasonically cleaned with acetone, alcohol and deionized water for 10 minutes each, rinsed with deionized water, dried with nitrogen, and placed on the substrate stage of the sputtering chamber.

[0025] Vacuum the chamber to 1×10 with a mechanical pump -1 Pa, the substrate was cleaned by plasma reverse sputtering with high-purity Ar. The plasma reverse sputtering cleaning parameters were set as follows: the sputtering pressure was 5Pa, the bias voltage was 700V, the duty cycle was 20%, and the reverse sputtering time was 8 minutes.

[0026] Use mechanical pump and molecular pump to pump the sputtering chamber to 2×10 -4 The background vacuum of Pa, and then start the preparation of the film, using radio frequency ...

Embodiment 2

[0029] The special target material of the present invention: ZnO: V target is installed on the target gun of magnetron sputtering equipment, and the atomic percentage of V / (V+Zn) in the target material is 1.79%, with Corning glass as the substrate, successively through Acetone, alcohol, and deionized water were ultrasonically cleaned for 10 minutes each, rinsed with deionized water, dried with nitrogen, and placed on the substrate stage of the sputtering chamber.

[0030] Vacuum the chamber to 1×10 with a mechanical pump -1 Pa, the substrate was cleaned by plasma reverse sputtering with high-purity Ar. The plasma reverse sputtering cleaning parameters were set as follows: the sputtering pressure was 5Pa, the bias voltage was 700V, the duty cycle was 20%, and the reverse sputtering time was 8 minutes.

[0031]Use mechanical pump and molecular pump to pump the vacuum chamber to 2×10 -4 The background vacuum of Pa, and then start the preparation of the film, using radio frequen...

Embodiment 3

[0034] The special target material of the present invention: ZnO: V target is installed on the target gun of magnetron sputtering equipment, and the atomic percentage of V / (V+Zn) in the target material is 1.79%, with quartz glass as the substrate, successively pass through Acetone, alcohol, and deionized water were ultrasonically cleaned for 10 minutes each, rinsed with deionized water, dried with nitrogen, and placed on the substrate stage of the sputtering chamber.

[0035] Vacuum the chamber to 1×10 with a mechanical pump -1 Pa, the substrate was cleaned by plasma reverse sputtering with high-purity Ar. The plasma reverse sputtering cleaning parameters were set as follows: the sputtering pressure was 5Pa, the bias voltage was 700V, the duty cycle was 20%, and the reverse sputtering time was 8 minutes.

[0036] Use mechanical pump and molecular pump to pump the sputtering chamber to 2×10 -4 The background vacuum of Pa, and then start the preparation of the film, using radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com