Method for preparing Ag-Ti-O antibacterial nanotube film on surface of titanium alloy

A technology of ag-ti-o and titanium alloy, applied in the direction of surface reaction electrolytic coating, metal material coating process, ion implantation plating, etc., can solve the problem of poor long-term antibacterial effect, limited dosage of doping elements, precipitation To improve the antibacterial ability and biological performance, strong long-term antibacterial ability, and accelerate the formation of new bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

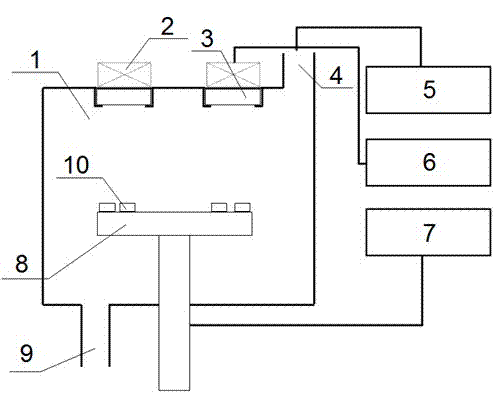

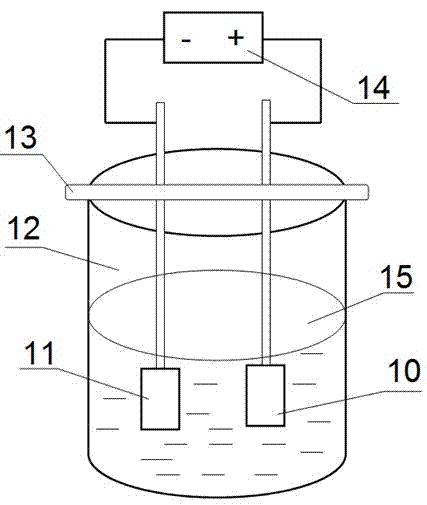

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

[0021] Such as figure 1 , 2 As shown, the TC4 titanium alloy specimen with a diameter of 14mm and a thickness of 2mm is now tested, and the operation steps are as follows:

[0022] (1) Pretreatment of titanium alloy specimens: mechanically grind and polish the titanium alloy specimens, and then sequentially immerse them in acetone, alcohol and distilled water for ultrasonic cleaning;

[0023] (2) Put the pretreated titanium alloy specimen 10 into such as figure 1 On the rotatable sample stage 8 in the vacuum chamber 1 of the pulsed DC magnetron sputtering coating equipment shown, the permanent magnet 2 is placed on the outer surface of the vacuum chamber 1, and the planar TiAg alloy used as the source of Ti and Ag in the film The target 3 is installed in the vacuum chamber 1 on the back of the permanent magnet 2, and the distance between the TiAg alloy target 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com