Preparation method of polymer carbon film for anti-wear and anti-friction surface modification of fluororubber, and fluororubber obtained by using carbon film

A fluorine rubber, modified technology, applied in the field of fluorine rubber, can solve problems such as lackluster methods, achieve low friction coefficient, good wear resistance, and avoid heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

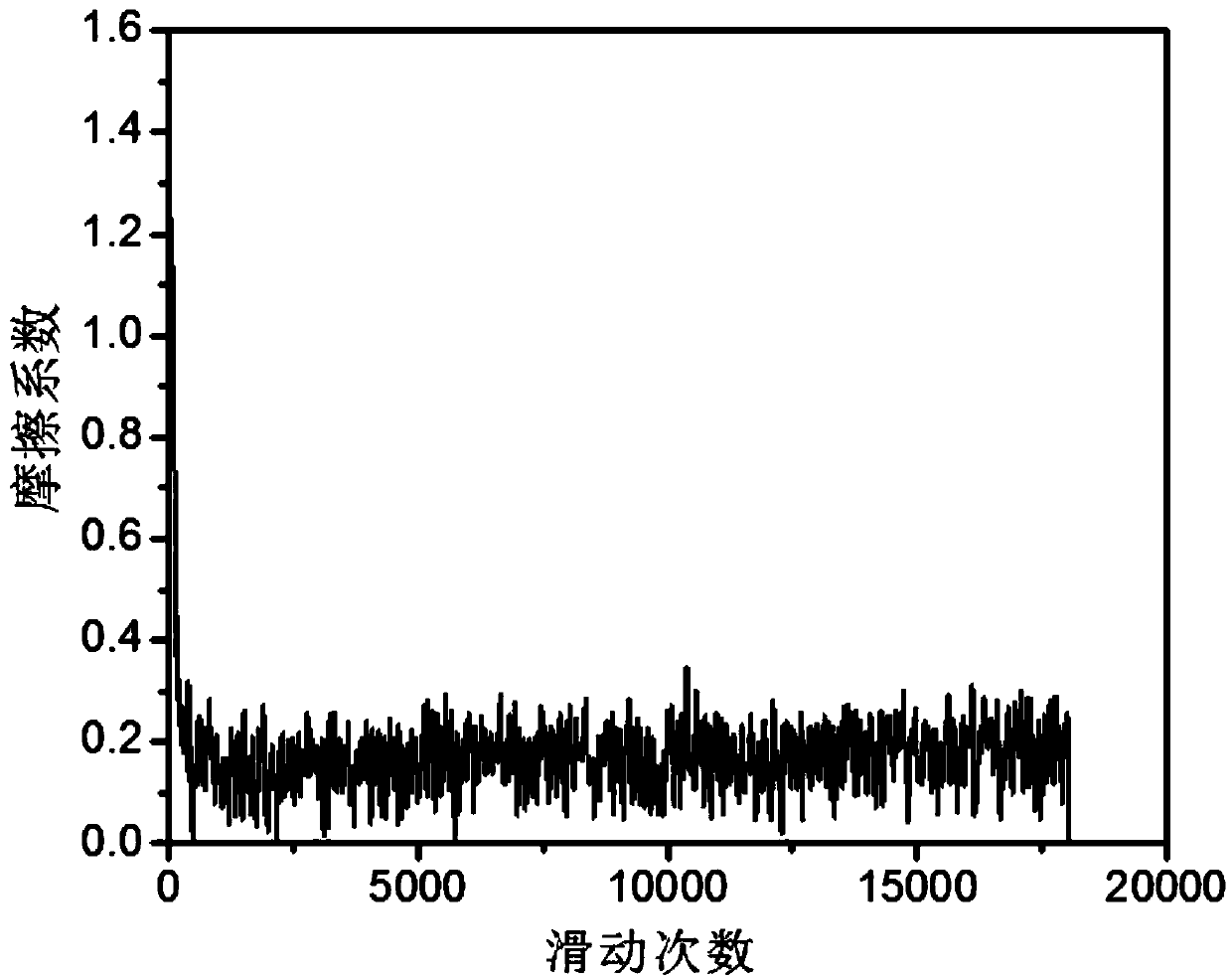

Embodiment 1

[0037] Fluorine rubber is used as the base material (thickness is 2mm), and the distance between the target and the base material is 9cm;

[0038] When the vacuum degree is higher than 2×10 -4 Pa, pass argon (Ar) in the deposition chamber, apply a DC bias voltage of 1000V to the substrate to generate Ar ions, and clean the substrate by sputtering for about 10 minutes;

[0039] CH 3 F, CH 4 Mix it with Ar in a ratio of 1:2:4 and pass it into the reaction chamber, and turn on the intermediate frequency DC sputtering power supply under the condition of 3.0Pa;

[0040] Control the sputtering power density of the target to 6W / cm 2 , and at the same time, under the action of self-bias, the charged ions are generated to bombard and sputter the high-purity graphite target to generate mixed plasma;

[0041]While sputtering the target, turn on the intermediate frequency pulsed DC bias power supply, control the voltage to 200V, and accelerate the mixed plasma generated above to reach...

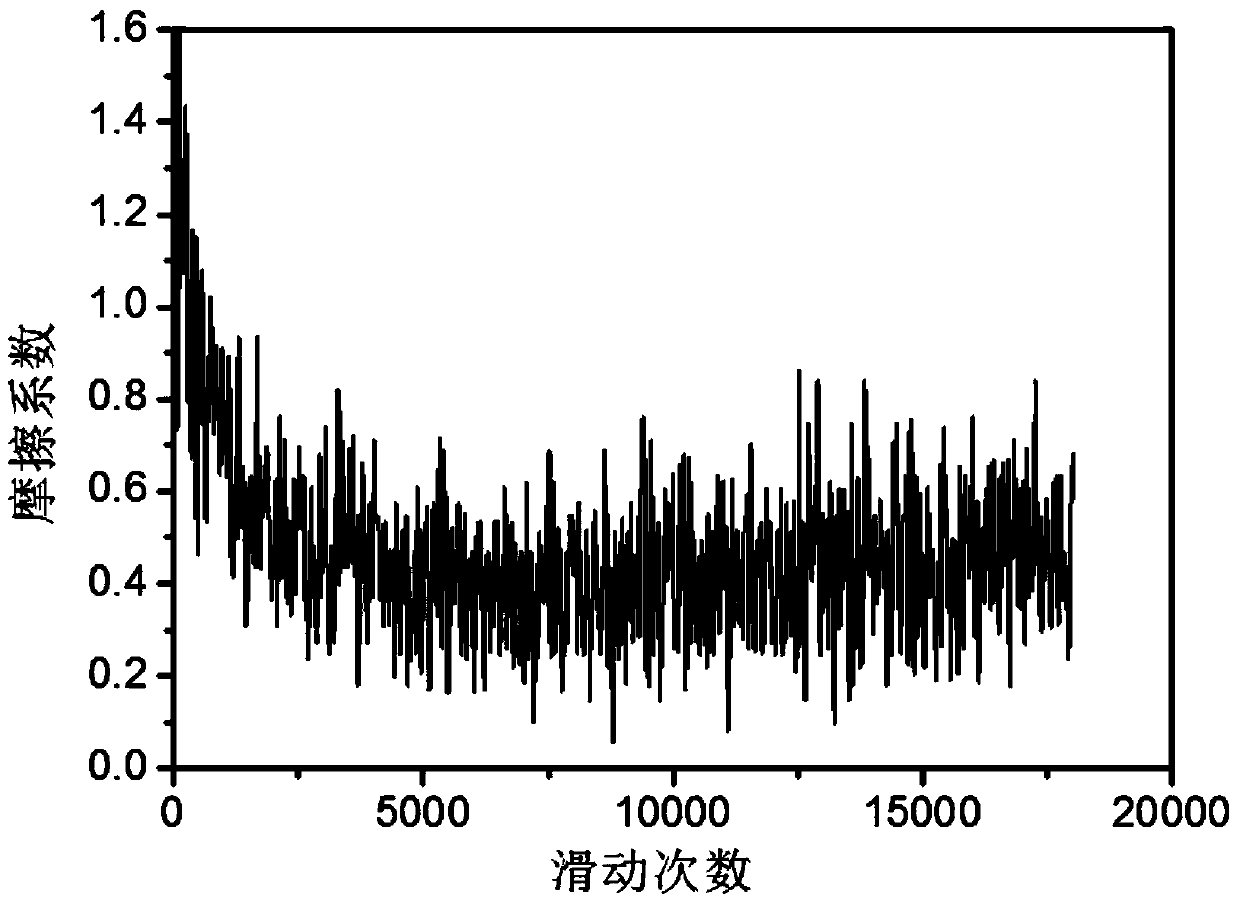

Embodiment 2

[0045] Fluorine rubber is used as the base material (thickness is 2mm), and the distance between the target and the base material is 9cm;

[0046] When the vacuum degree is higher than 2×10 -4 Pa, pass argon (Ar) in the deposition chamber, apply a DC bias voltage of 1000V to the substrate to generate Ar ions, and clean the substrate by sputtering for about 10 minutes;

[0047] CH 3 F, CH 4 Mix with Ar in a ratio of 1:2:3 and pass it into the reaction chamber, and turn on the intermediate frequency DC sputtering power supply under the working pressure of 3.0Pa;

[0048] Control the sputtering power density of the target to 6W / cm 2 , and at the same time, under the action of self-bias, the charged ions are generated to bombard and sputter the high-purity graphite target to generate mixed plasma;

[0049] While sputtering the target, turn on the intermediate frequency pulsed DC bias power supply, control the voltage to 200V, accelerate the mixed plasma generated above to reac...

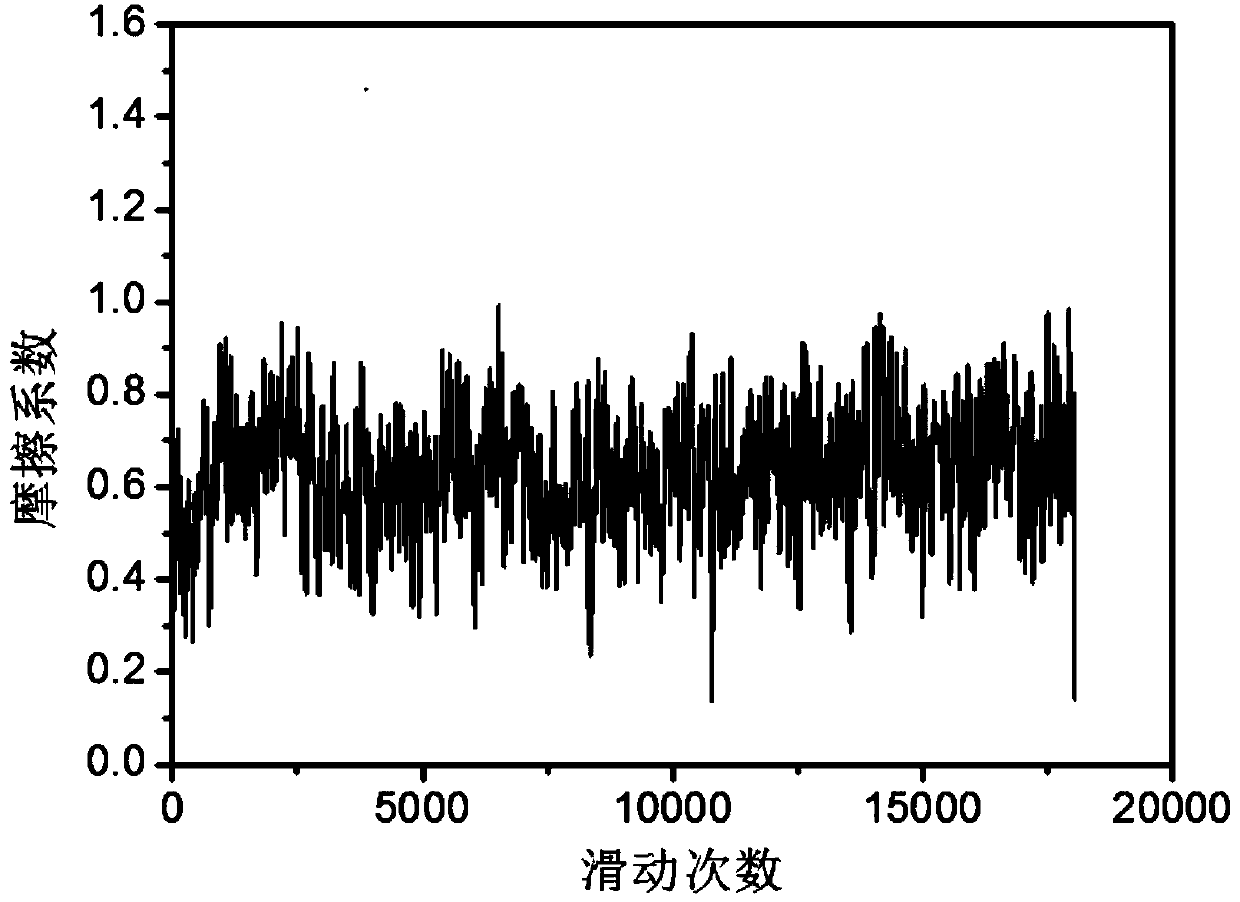

Embodiment 3

[0052] Fluorine rubber is used as the base material (thickness is 2mm), and the distance between the target and the base material is 9cm;

[0053] When the vacuum degree is higher than 2×10 -4 Pa, pass argon (Ar) in the deposition chamber, apply a DC bias voltage of 1000V to the substrate to generate Ar ions, and clean the substrate by sputtering for about 10 minutes;

[0054] CH 3 F, CH 4 Mix with Ar in a ratio of 1:2:5 and pass it into the reaction chamber, and turn on the intermediate frequency DC sputtering power supply under the condition of 3.0Pa;

[0055] Control the sputtering power density of the target to 6W / cm 2 , and at the same time, under the action of self-bias, the charged ions are generated to bombard and sputter the high-purity graphite target to generate mixed plasma;

[0056] While sputtering the target, turn on the intermediate frequency pulsed DC bias power supply, control the voltage to 200V, accelerate the mixed plasma generated above to reach the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com