Super-lubricated surface strengthening method of graphite-like carbon film for high-speed gear

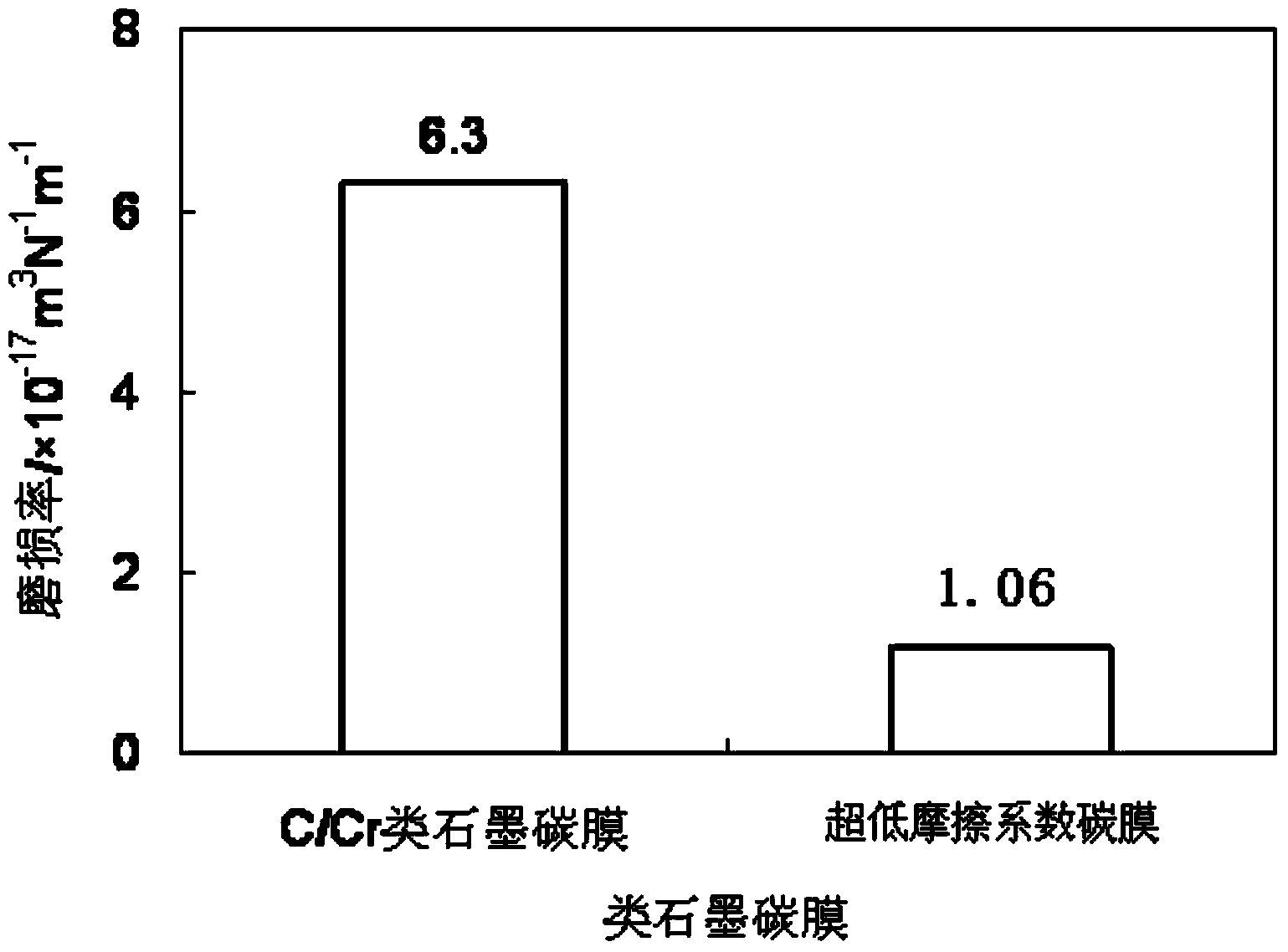

A surface strengthening, high-speed gear technology, applied in the field of super-lubricating surface enhancement of high-speed gears with graphite carbon film, can solve problems such as low lubricating film life, improve friction and wear performance, reduce vibration noise, and reduce gear vibration noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

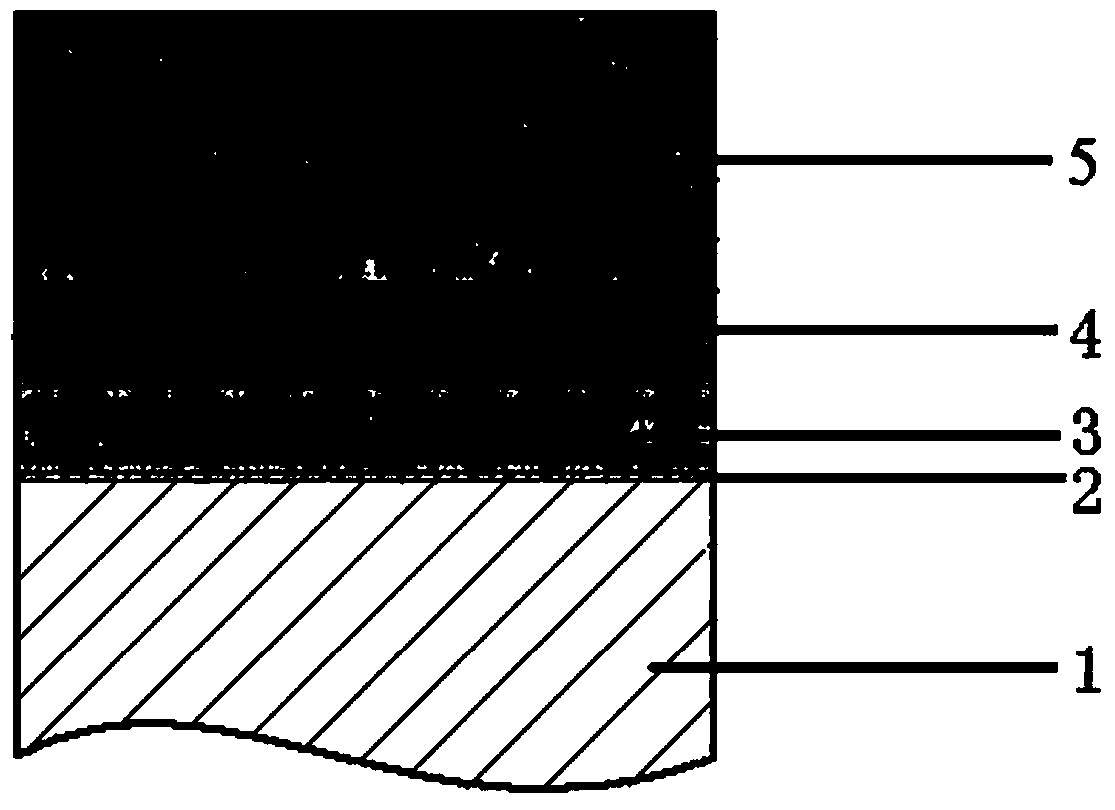

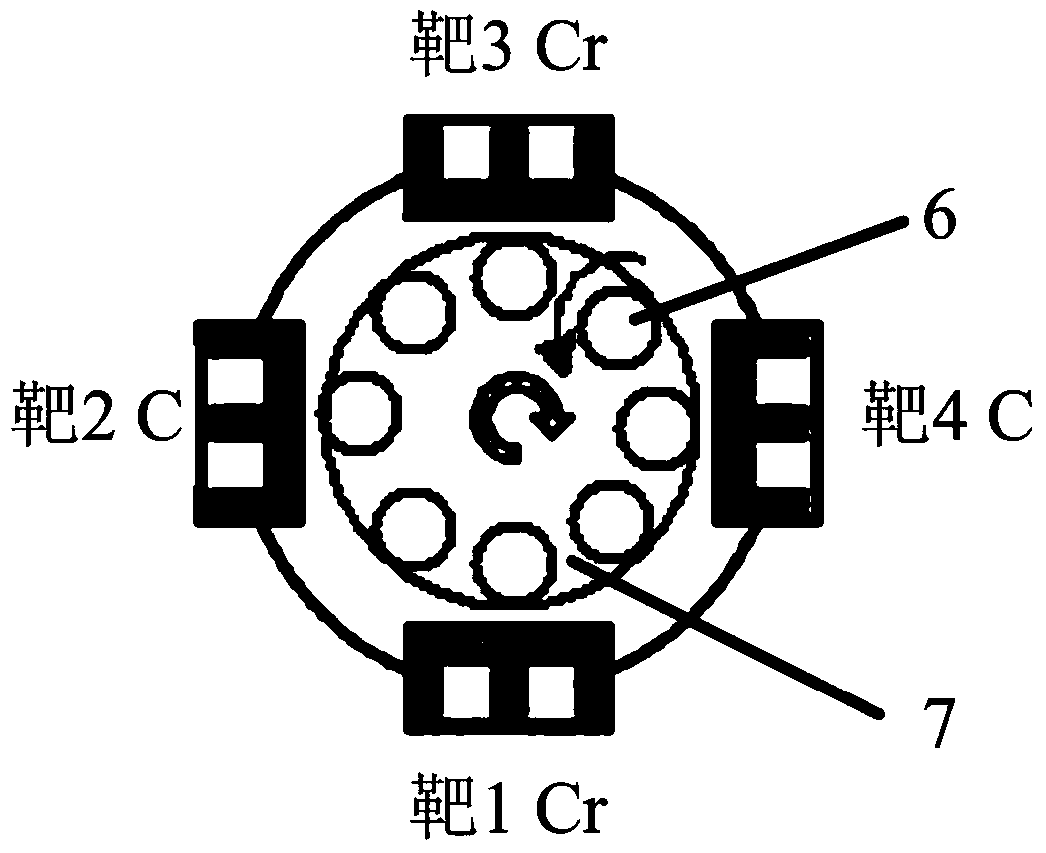

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A method for strengthening the super-lubricating surface of high-speed gear class graphite carbon film, comprising the following steps:

[0027] Step 1: Use conventional shot peening and enhanced shot peening to perform shot peening treatment on the gear surface to improve the stress state of the gear surface, remove gear burrs, oxides and surface processing tool marks, and use ceramic particles with a particle size in the range of 10 to 60 μm to treat the gear. Sandblasting the surface to remove oxides and improve the surface roughness of the gear, and then adopt fluid polishing technology to make the surface finish of the gear less than 0.2μm, and control the amount of fluid polishing on the gear surface within 5μm, and then use ultrasonic dewaxing and degreasing cleaning Treat the surface of the gear for 10-15 minutes each, then rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com