Patents

Literature

33results about How to "Improve glue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

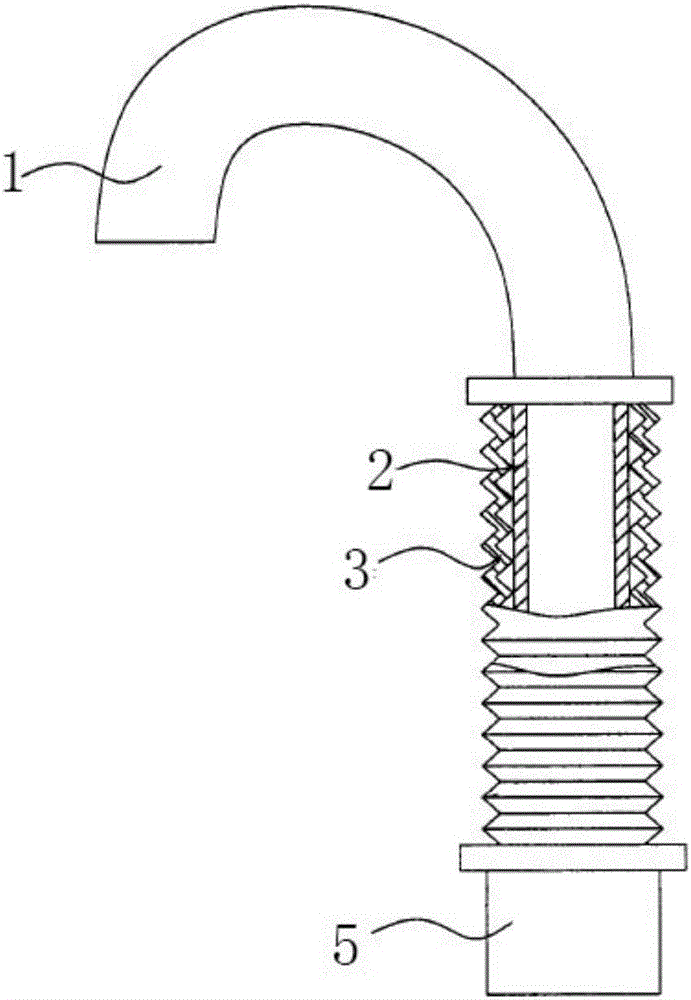

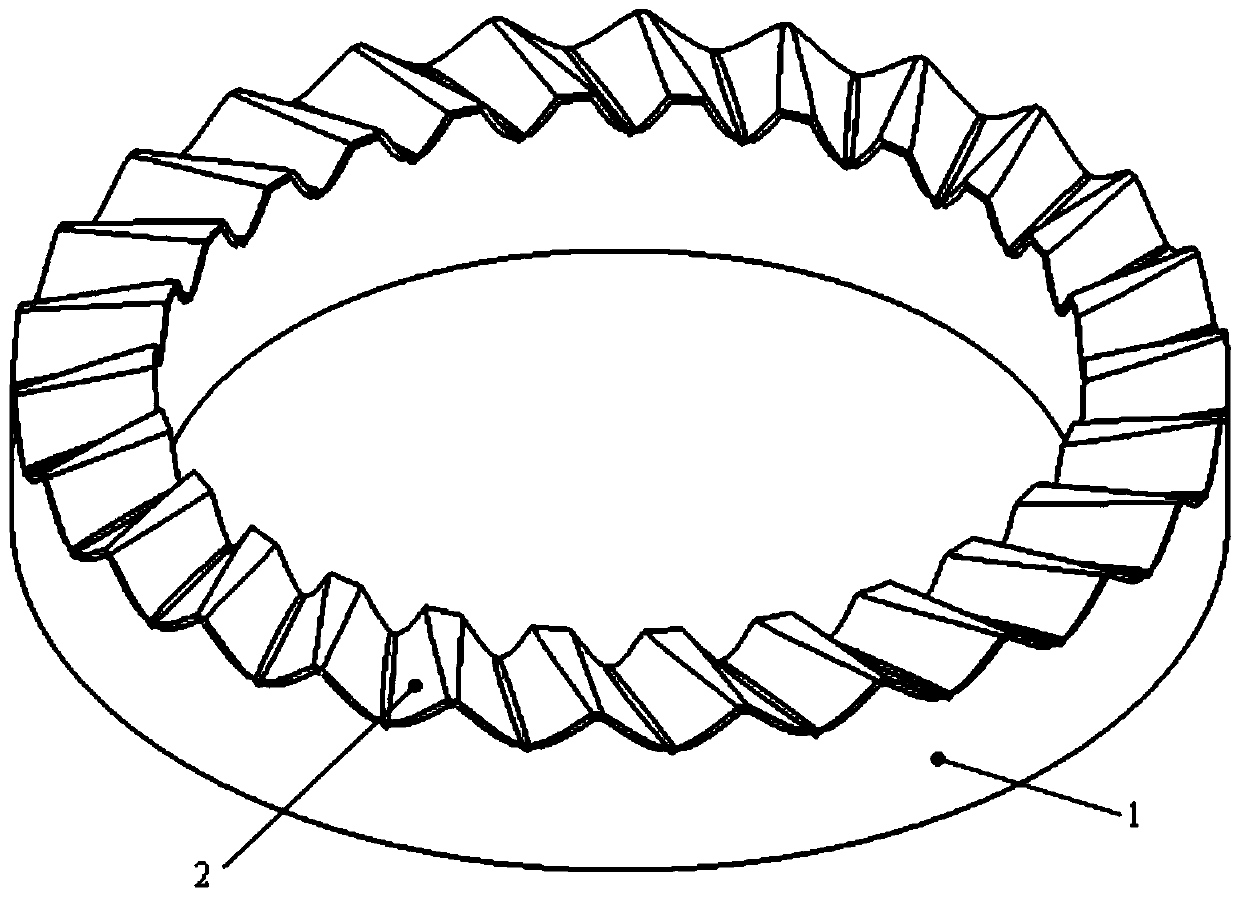

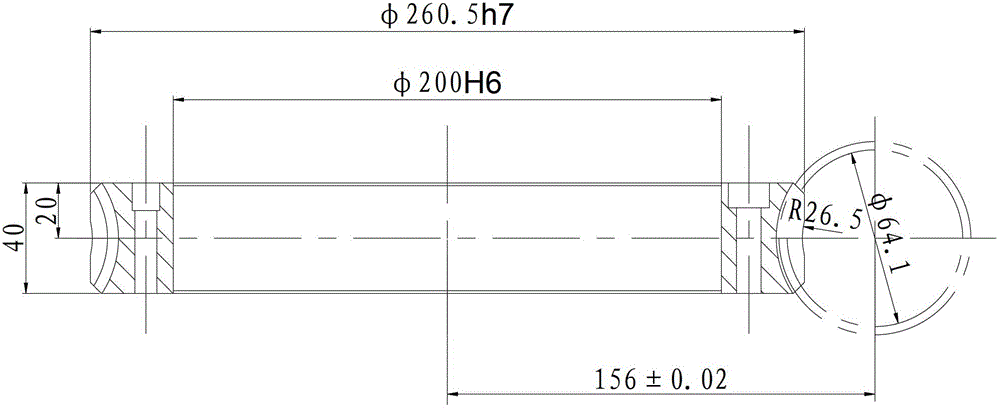

Mine vehicle axle wheel reductor planetary gear and manufacture method thereof

ActiveCN102979884AGood contact fatigue strengthImprove reliabilityPortable liftingGear lubrication/coolingGear wheelReduction drive

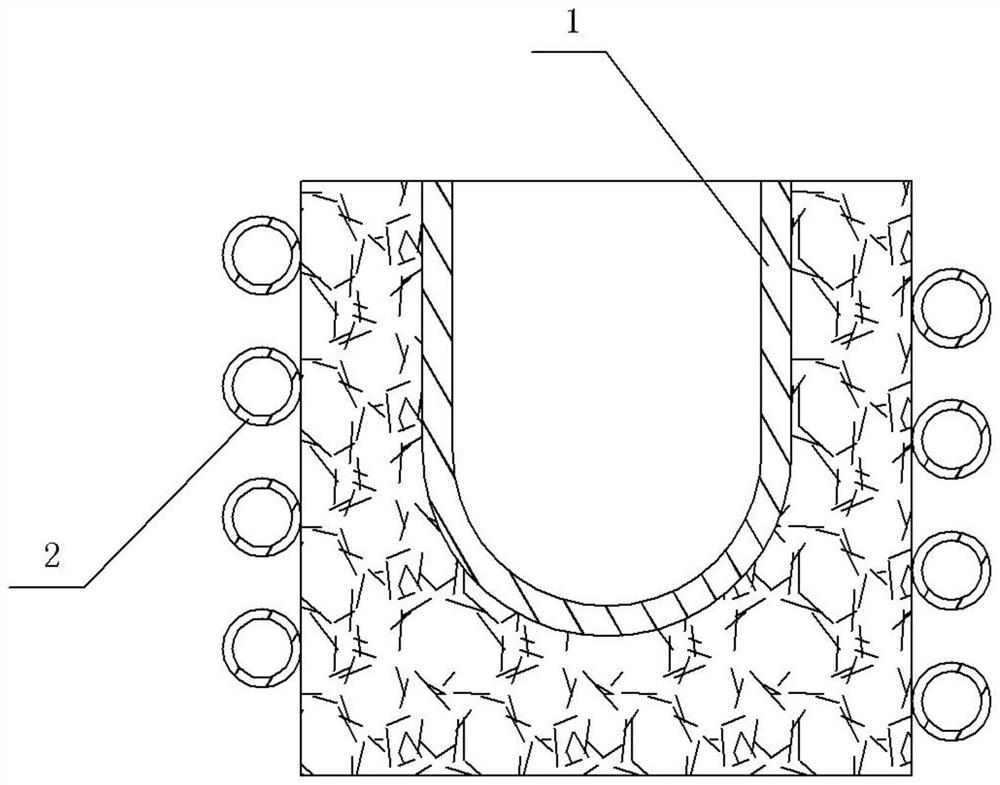

The invention relates to a mine vehicle axle wheel reductor planetary gear and a manufacture method thereof. The manufacture method comprises the following processing steps of: (1) forging to obtain a gear ring; (2) roughly turning; (3) carrying out preheat treatment; (4) finely turning; (5) carrying out ultrasonic flaw detection; (6) hobbing; (7) boring a plurality of oilholes in the wall of a planet wheel inner hole in the middle of the gear ring along the radial direction of the planet wheel inner hole; (8) carburizing for heat treatment; (9) performing plain grinding on two end faces of the gear ring to the required size and then grinding the planet wheel inner hole of the gear ring to the required size; (10) grinding the gear; (11) carrying out magnetic powder inspection; (12) strengthening shot peening at gear root; and (13) carrying out manganese phosphating. The planetary gear produced by adopting the manufacture method, disclosed by the invention has the advantages that the contact fatigue strength is better, the reliability is greatly enhanced and the service life is greatly prolonged; and according to the manufacture method provided by the invention, shot peening strengthening is adopted in processing the gear root, and the stress state of the gear root is changed, so that the gear root bending strength of the planetary gear is remarkably enhanced, the strength of the planetary gear is enhanced and the service life of the planetary gear is prolonged.

Owner:WUXI WEIFU CHINA ITAL GEAR

Electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating, and production process of electroplating liquid

ActiveCN104562105AImprove wear resistanceImprove glue resistanceElectrolytic coatingsNanotechnologyBiological activationChrome plating

The invention relates to an electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating. The electroplating liquid comprises the following components according to the ratio: 100-165 g / l of nickel sulfate, 80-136g / l of cobaltous sulfate, 40-50 g / l of boric acid, 3-9 g / l of potassium chloride, 5-38 g / l of nano tungsten disulfide plating pulp, 3-5 g / l of a brightening agent and saccharin, 0.3-0.7 g / l of a wetting agent (lauryl sodium sulfate), and 20 g / l of sodium citrate. A production process of the electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating comprises the following steps: (1) checking before plating, (2) product hanging, (3) high-temperature degreasing, (4) electrolytic degreasing, (5) washing with deionized water, (6) activation with weak acid, (7) nickel preplating, (8) electroplating, (9) washing and recycling, and (10) heat treatment for removing hydrogen. Through the adoption of the electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating, and the production process of the electroplating liquid, which are provided by the invention, the overall performance and the life cycle of an electroplated layer can completely exceed those of the existing hard chrome plated layer, the environment is protected, and the energy is saved.

Owner:长沙润佰特新材料科技有限公司

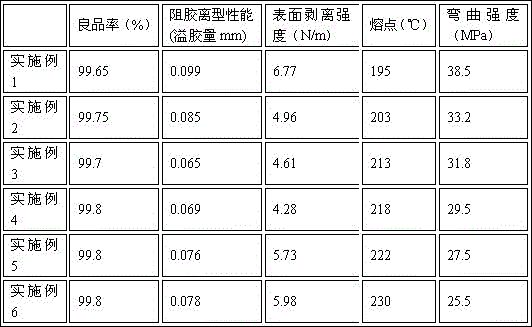

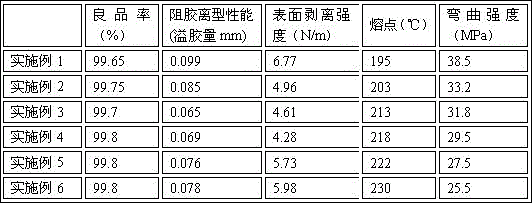

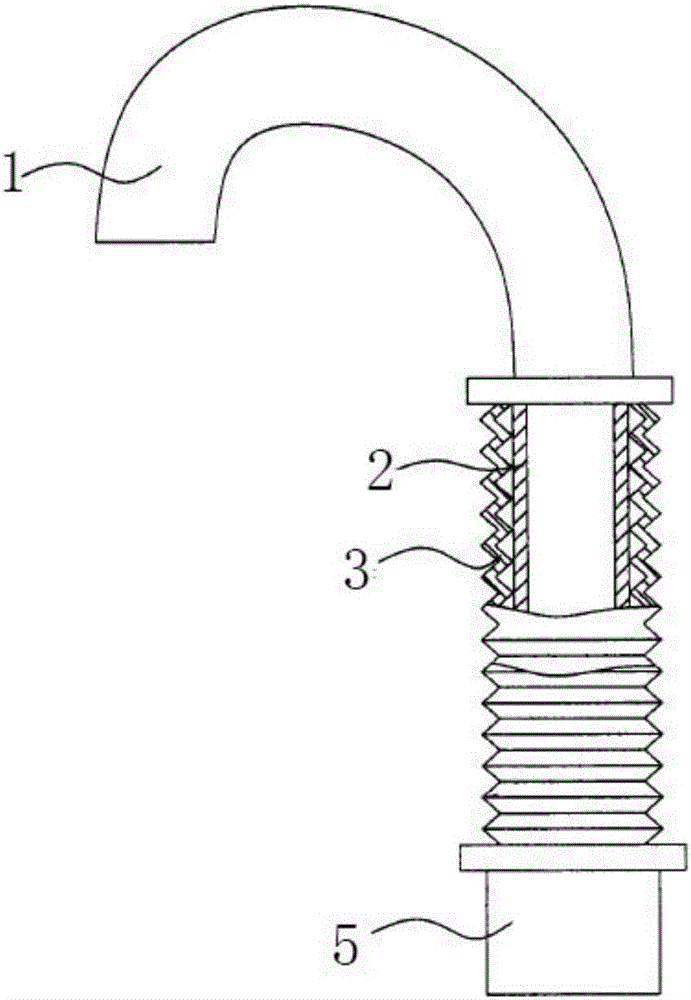

Flexible circuit board gum inhibition release paper release layer hot-melt resin composition, gum inhibition release paper and production method of gum inhibition release paper

ActiveCN105926362AHigh melting pointImprove surface peel strengthNon-fibrous pulp additionPaper coatingFlexible circuitsFlexural strength

The invention discloses a flexible circuit board gum inhibition release paper release layer hot-melt resin composition, a gum inhibition release paper and a production method of the gum inhibition release paper. The hot-melt resin composition comprises, by mass, 5-30 parts of polypropylene, 60-85 parts of poly(4-methyl-1-pentene), 0-5 parts of polyethylene and 5-20 parts of polybutylene terephthalate; and the flexible circuit board gum inhibition release paper is formed through coating the surface of paper with the hot-melt resin composition in a hot melt manner and through carrying out high frequency corona to form surface micro-pores. Combination of hot-melt coating and high frequency corona micro-pore technologies changes the overflow amount of an adhesive in the hot pressing process of a flexible circuit board in order to improve the gum inhibition function, and modified resin is added to improve the melting point, the surface peeling strength and the bending strength of a release layer, so the yield is improved; the production method has the advantages of simplicity, easy process control and low cost; and the gum inhibition release paper has the advantages of excellent gum inhibition release performance, very low peeling strength, high temperature resistance and high bending strength.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

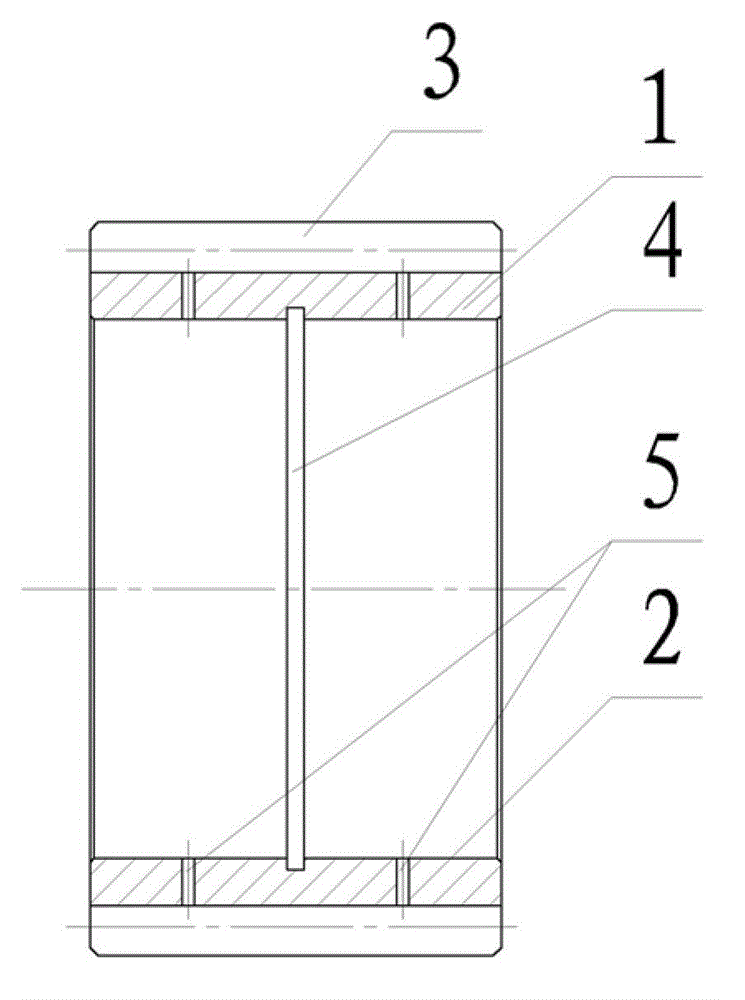

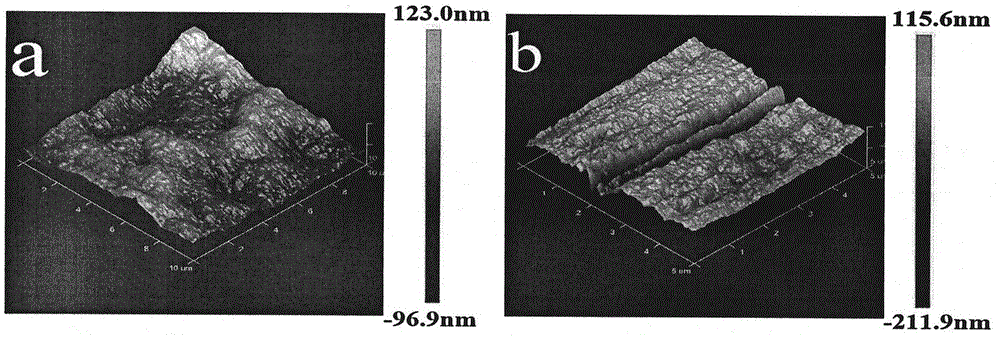

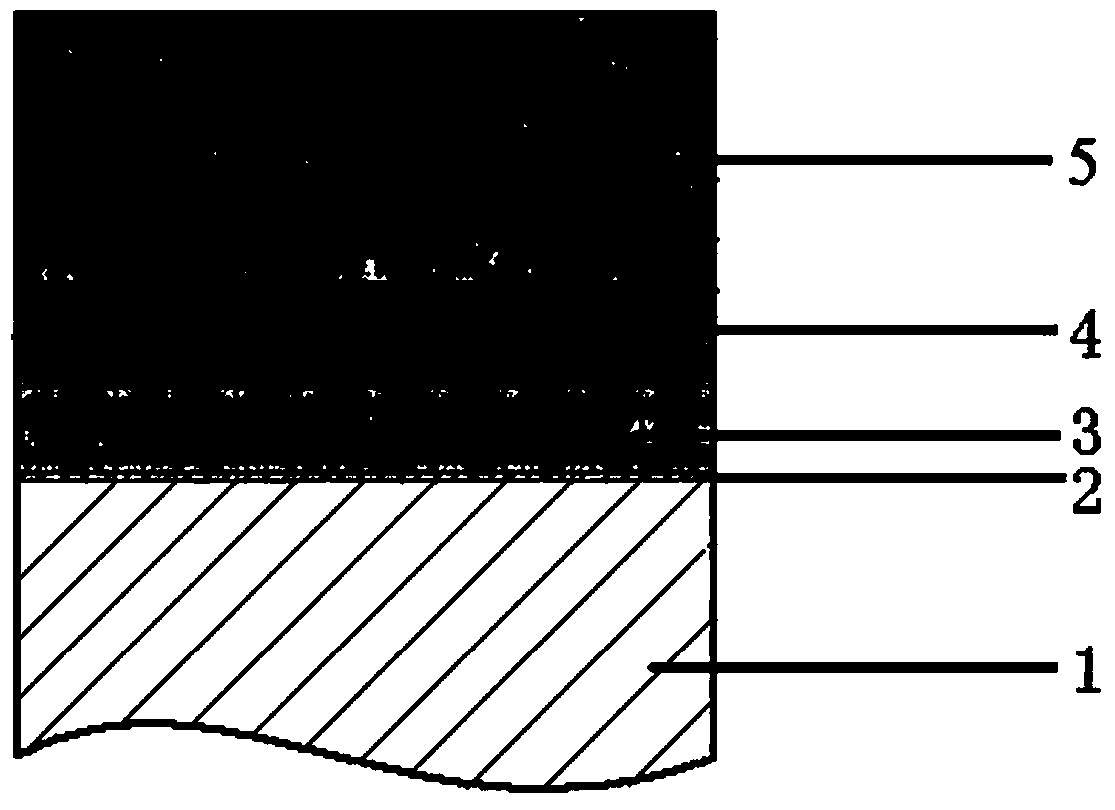

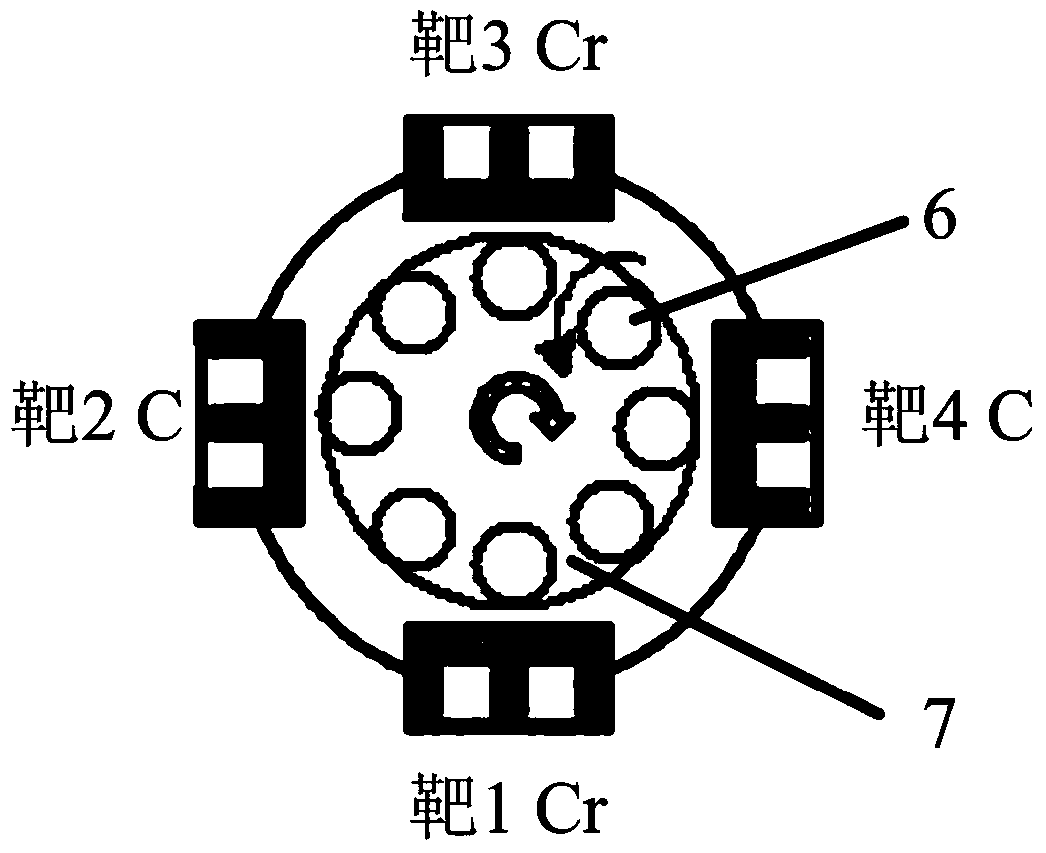

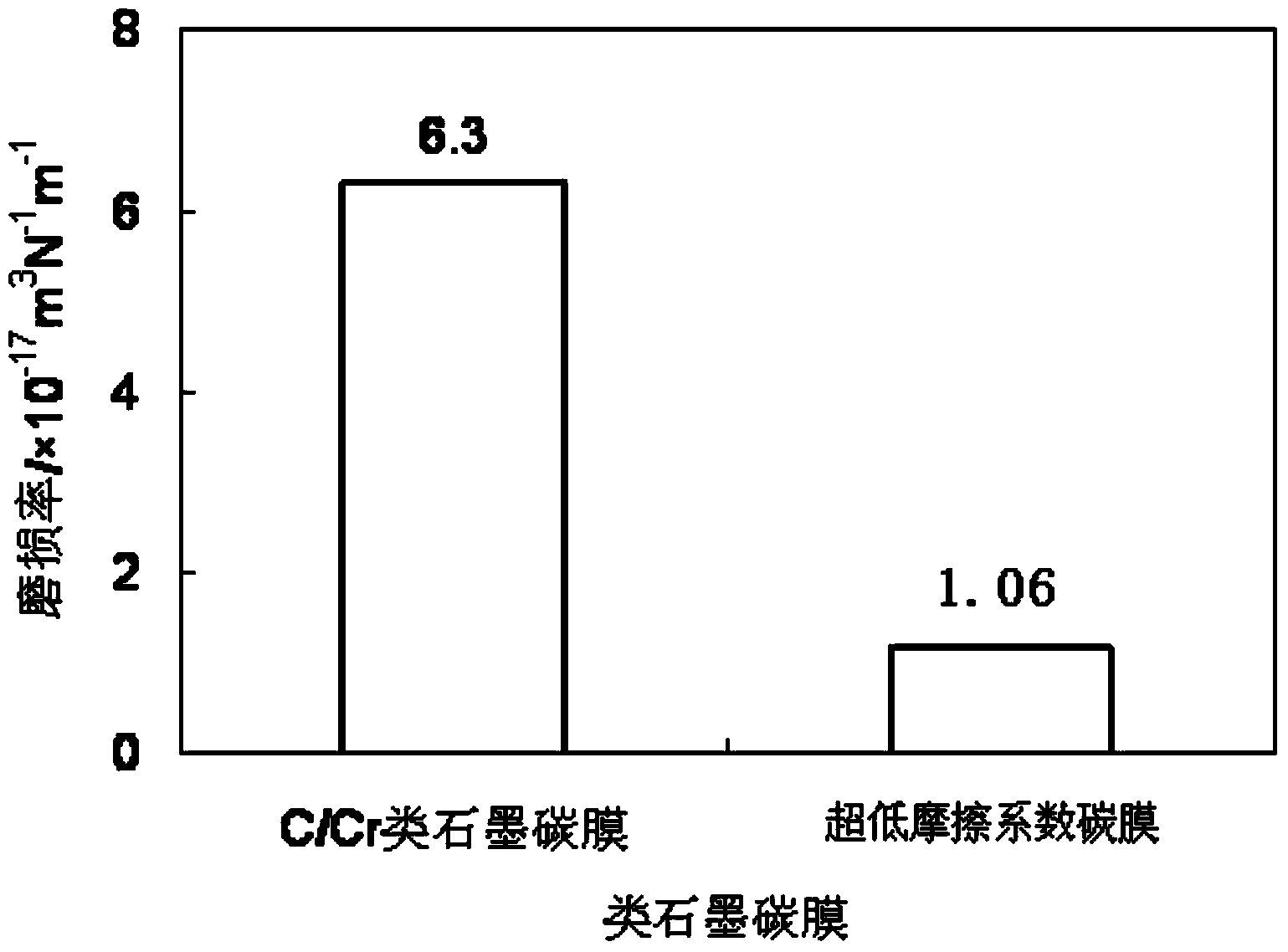

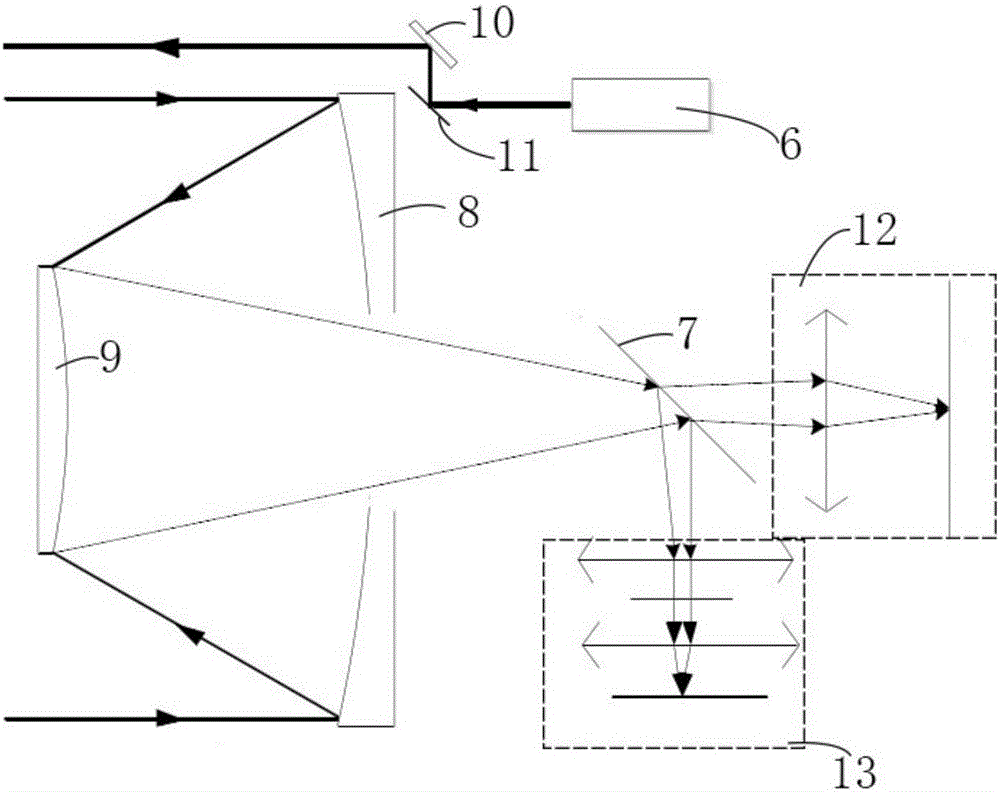

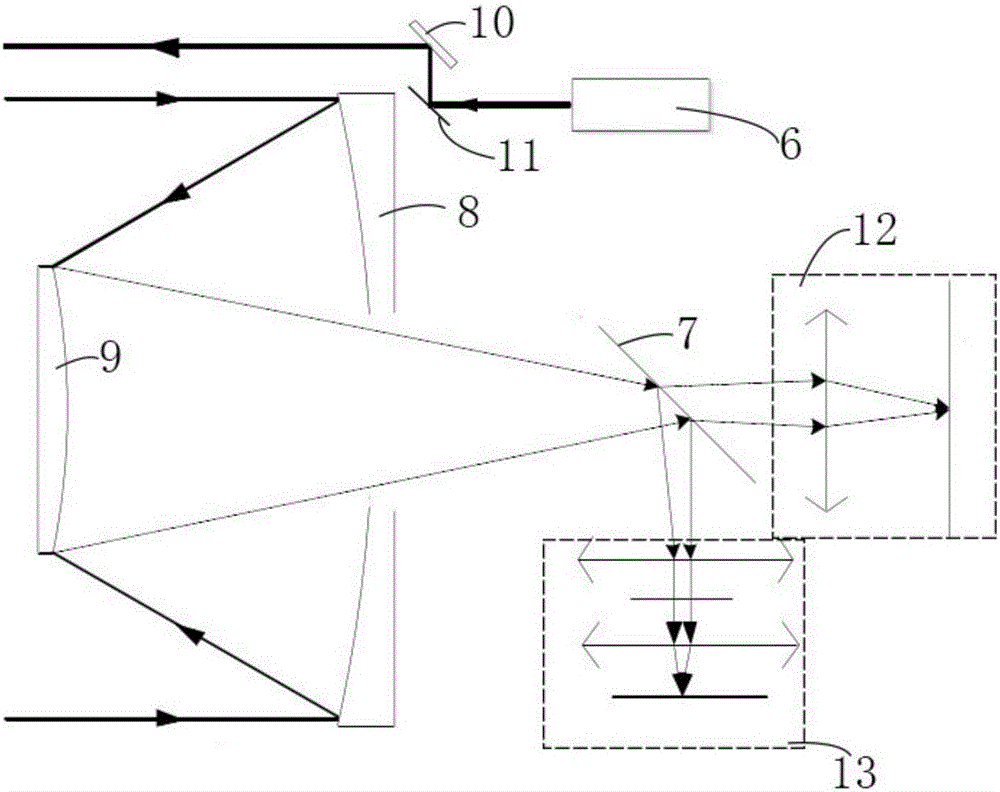

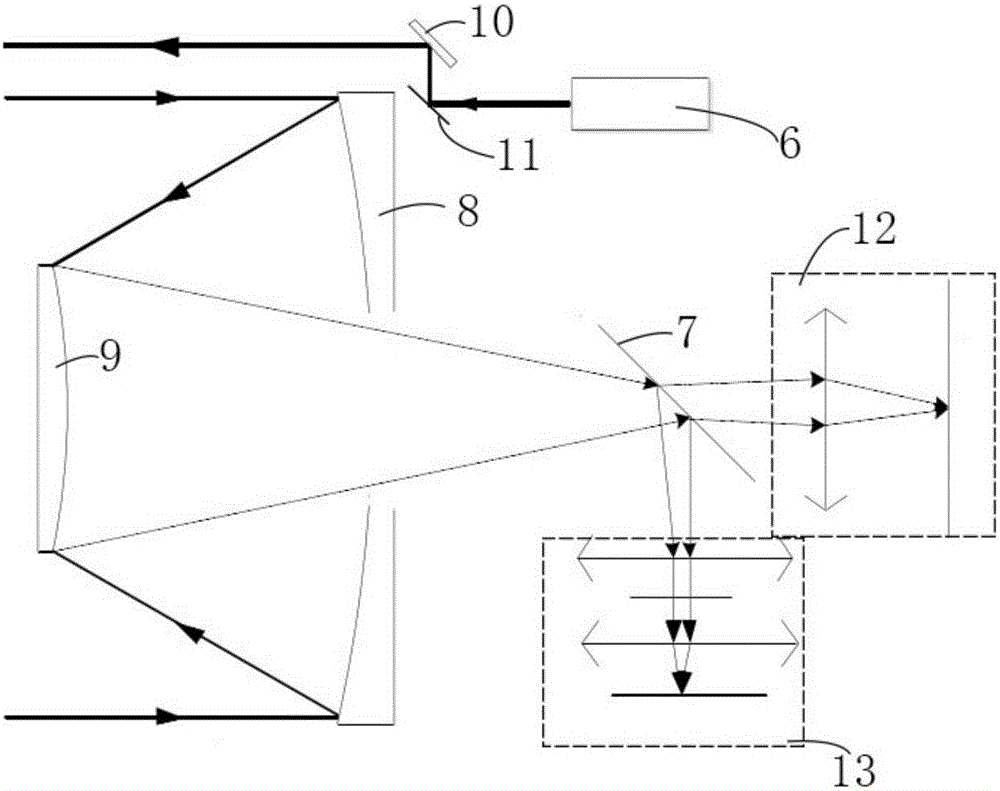

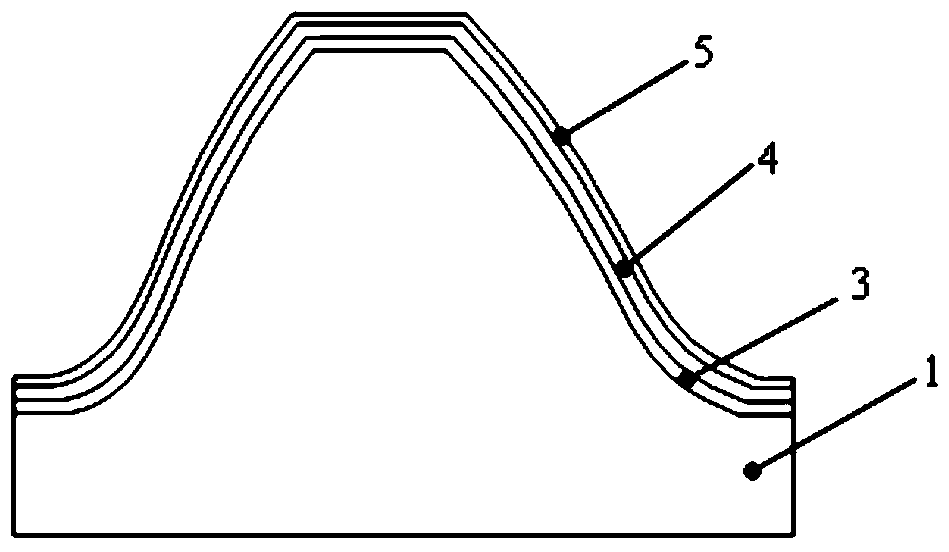

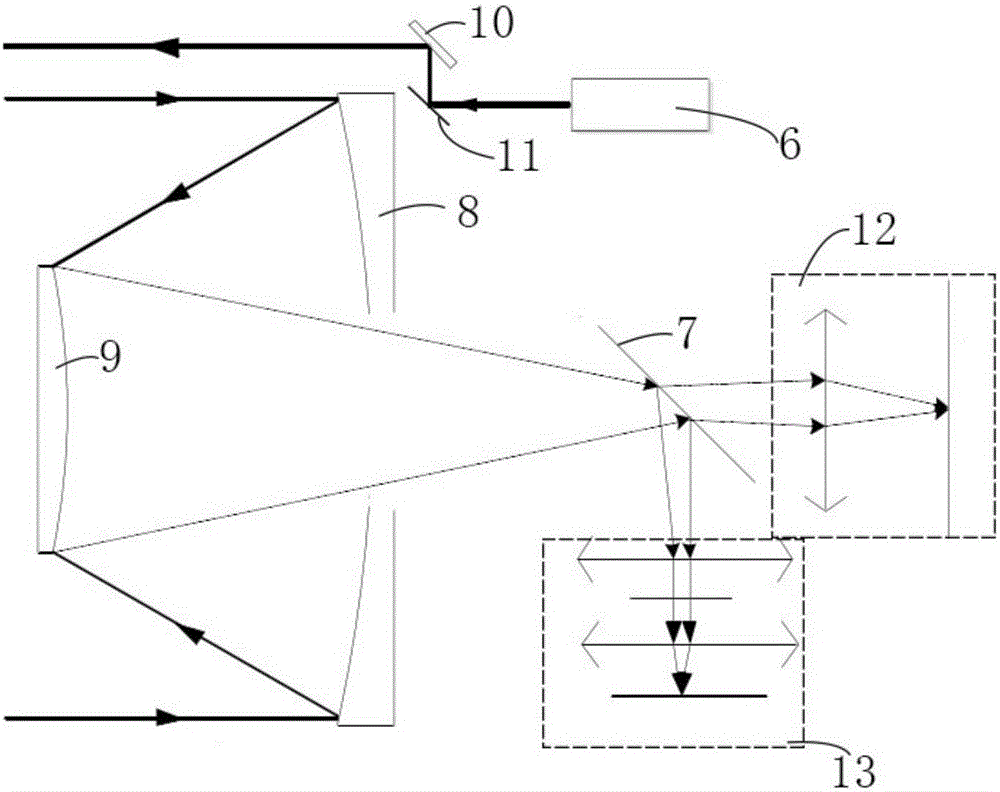

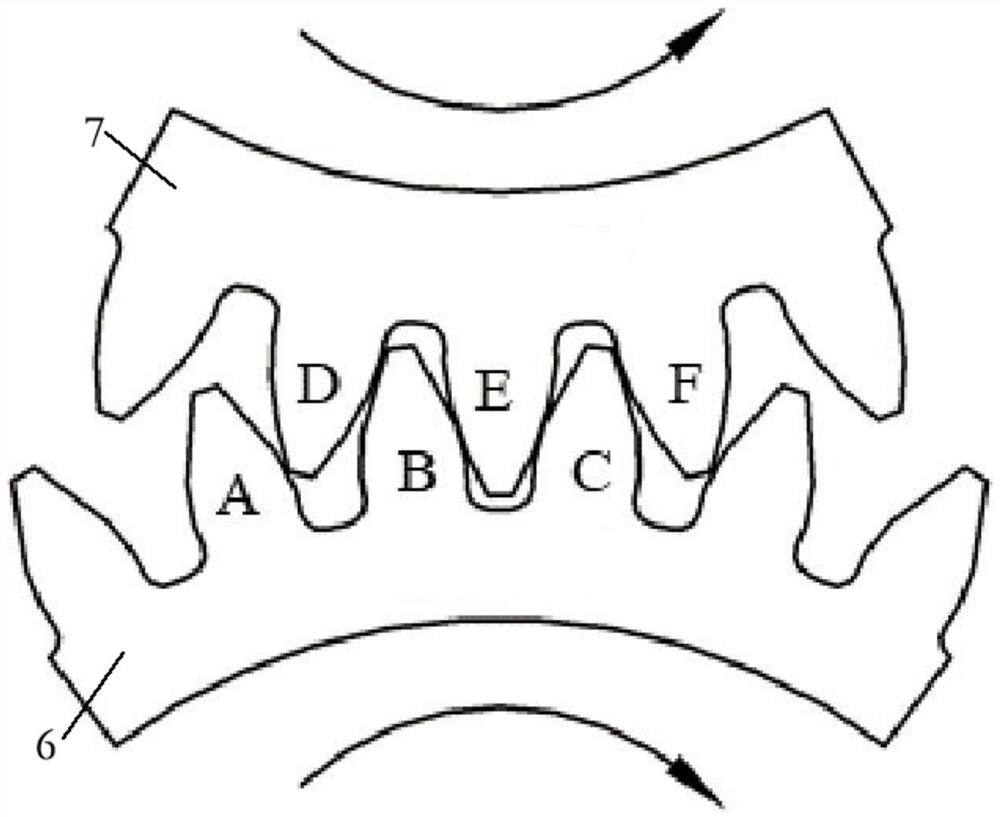

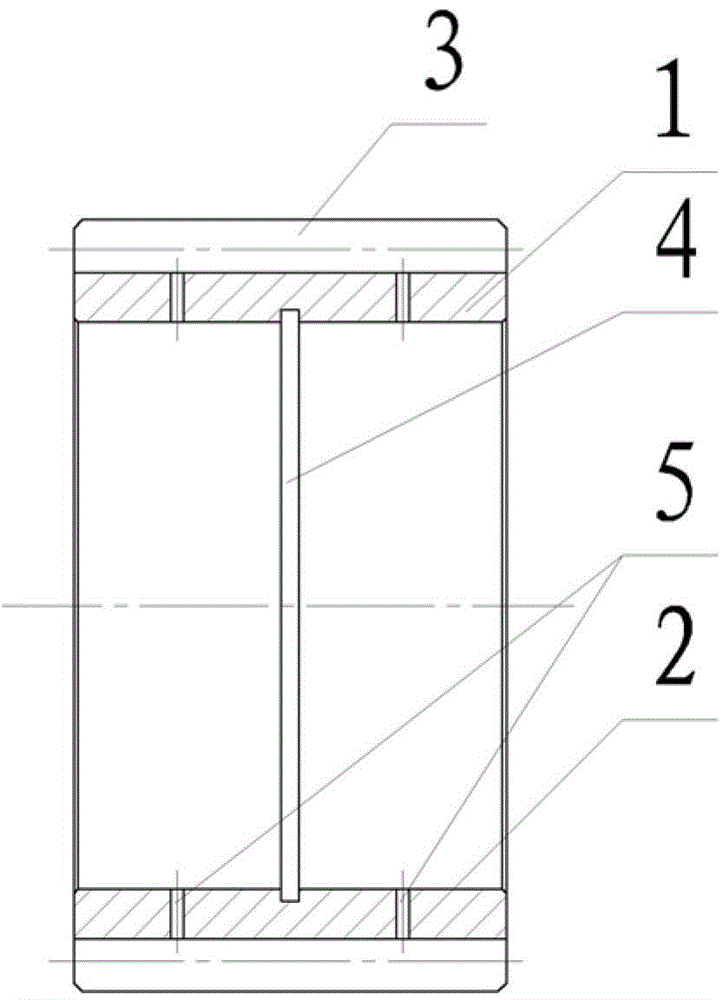

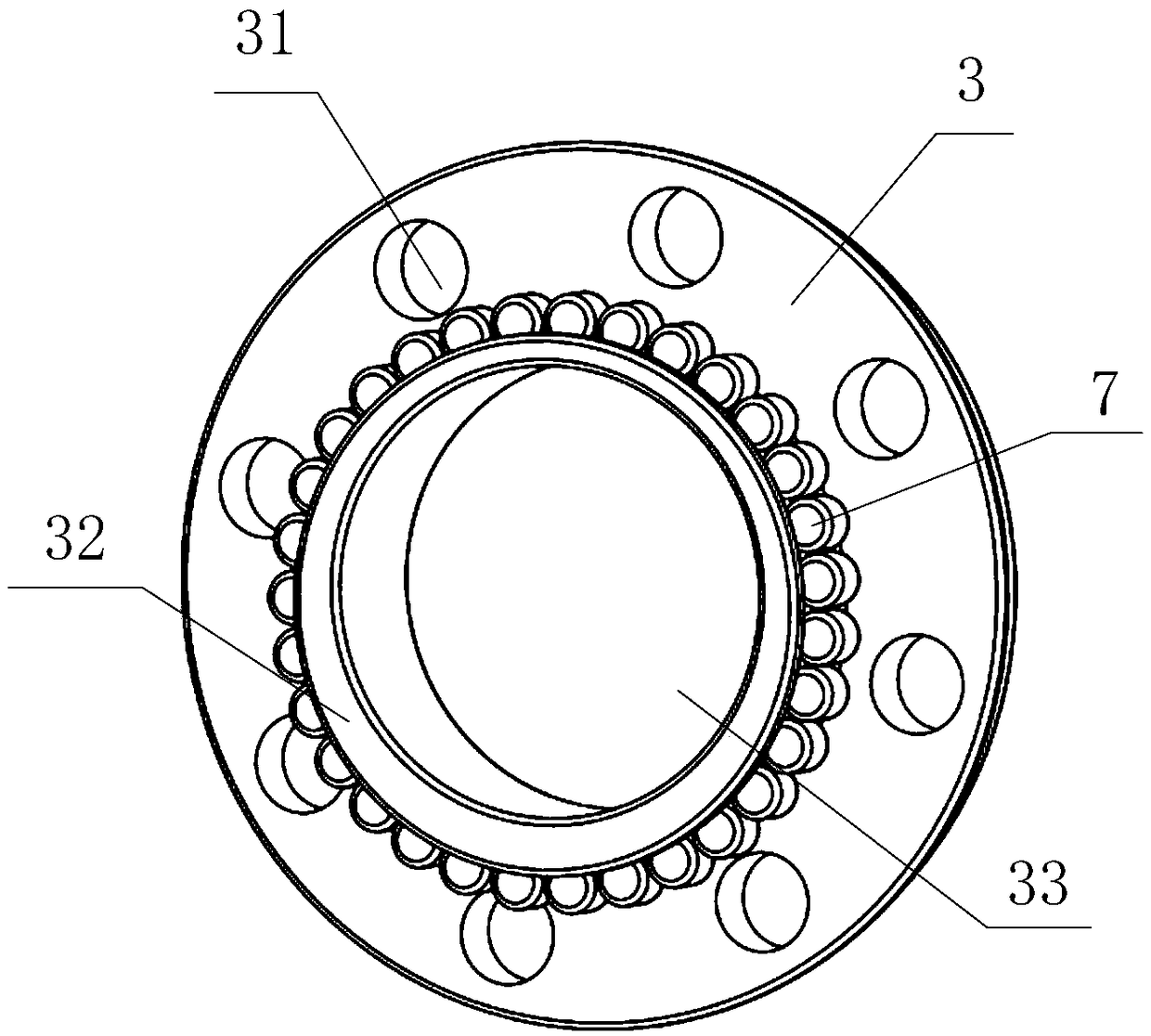

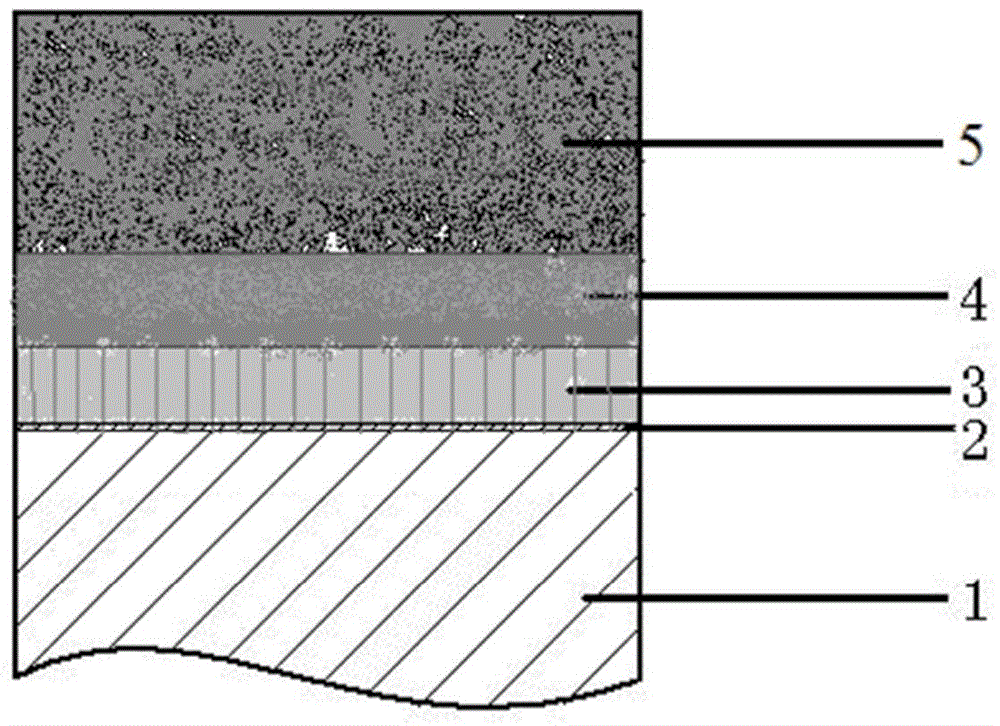

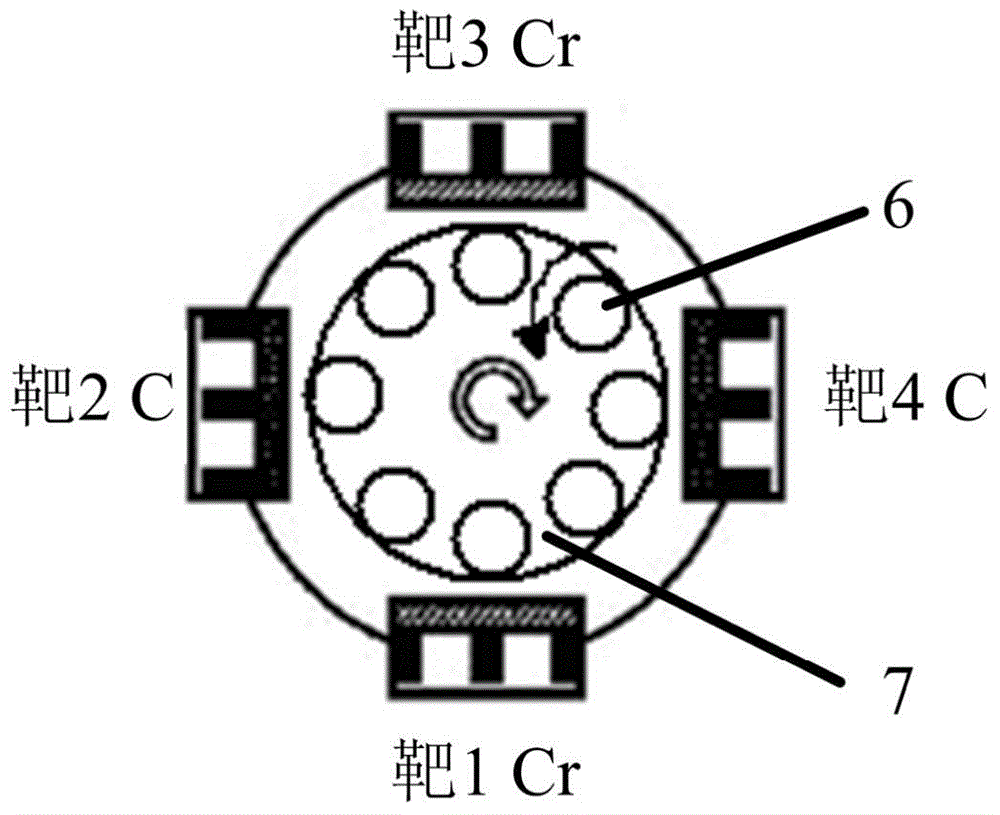

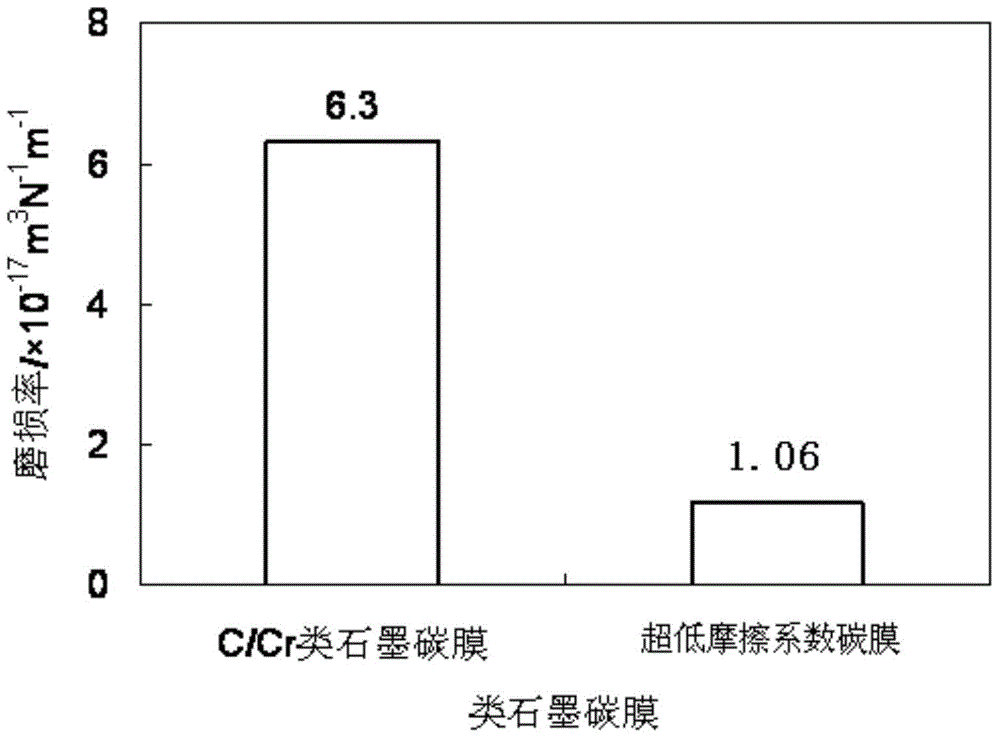

Super-lubricated surface strengthening method of graphite-like carbon film for high-speed gear

ActiveCN103469217AImprove friction and wear performanceImprove transmission efficiencySurface finishCarbon film

The invention relates to a super-lubricated surface strengthening method of a graphite-like carbon film for a high-speed gear. The method comprises the following steps: firstly, sequentially carrying out shot blasting, micro-jetting and fluid polishing pre-treatment on the surface of the gear to enable the surface smoothness of the gear to be less than 0.2 micron; then, by adopting an unbalanced magnetron sputtering composite target technology, introducing elements such as Y and Ta into a graphite-like carbon film preparation technology to prepare a graphite-like carbon film with ultralow friction coefficient on the surface of the gear, namely carrying out sputter cleaning on the surface of a base metal 1; and sequentially preparing a Cr transitional layer 3, a Cr / C gradient layer 4 and a graphite-like composite work layer 5 with ultralow friction coefficient on a fluid polishing surface layer 2. The method provided by the invention solves the problem that a solid lubricating film of the high-speed gear is short in service life, and the vibrating noise of the high-speed gear is effectively reduced. The vibrating noise of a transmission gear by adopting the technology is reduced by 10-15%, so that the method provides a novel technical path for reducing the vibrating noise of the gear.

Owner:CSIC NO 12 RES INST

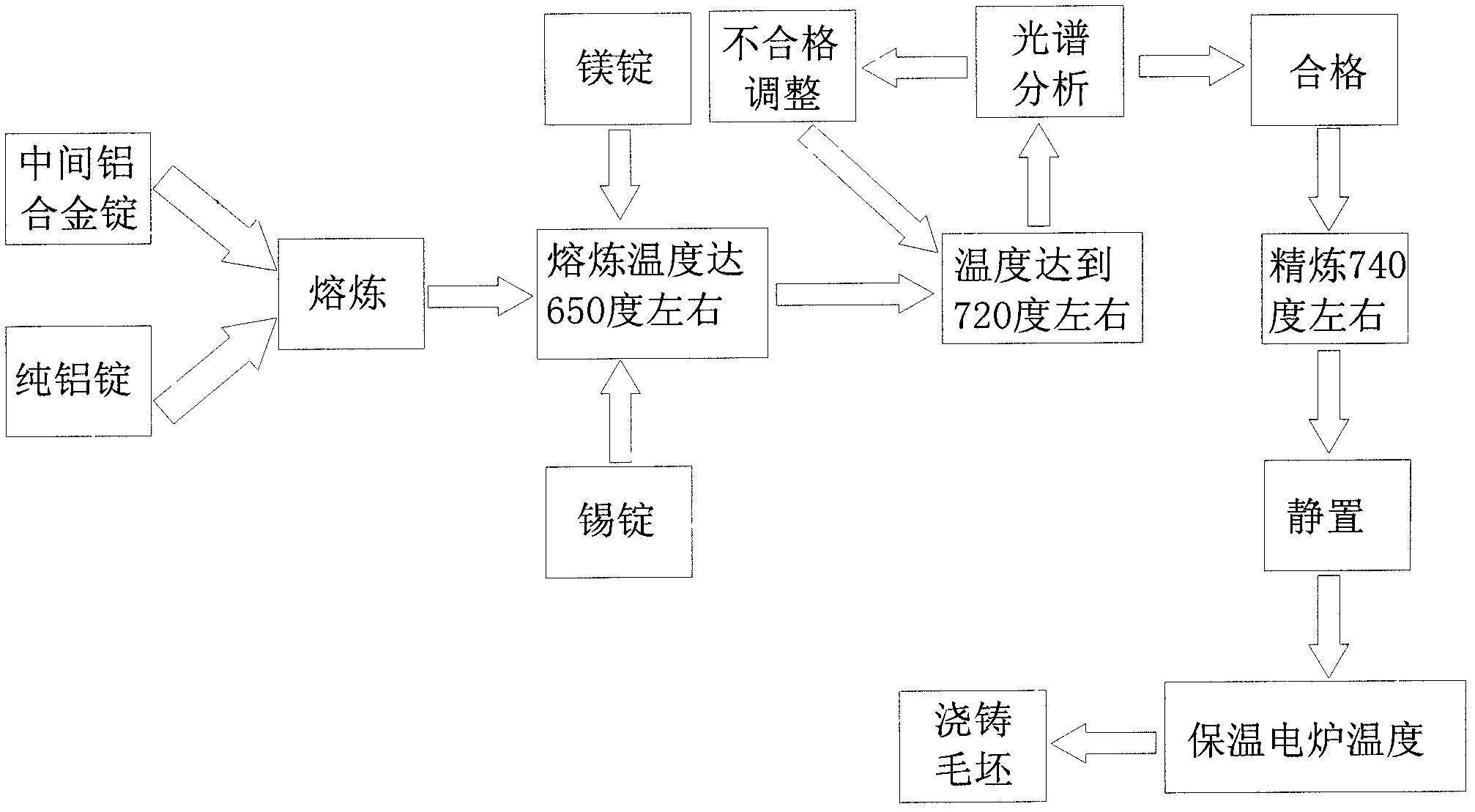

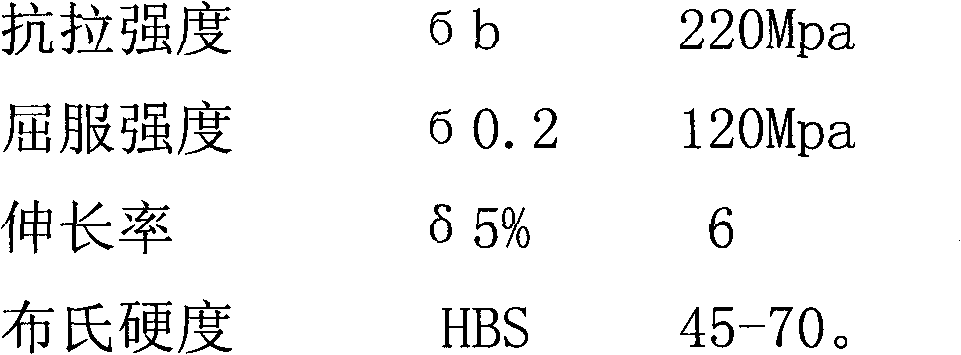

Special aluminum alloy preparation technology

The invention relates to an alloy material, and especially relates to a special aluminum alloy preparation technology. The technology is characterized in that the technology comprises the following steps: smelting pure aluminum ingots and master aluminum alloy ingots in a smelting furnace, adding magnesium and tin ingots when the smelting temperature in the smelting furnace reaches 640-660DEG C, smelting, analyzing the smelted materials through adopting spectral analysis when the smelting temperature reaches 710-730DEG C, refining at 730-750DEG C if the materials are qualified, carrying out adjusted smelting if the materials are not qualified, allowing the materials to stand for 10-20min after the refining completion, putting the materials in a heat-insulation electric furnace, carrying out heat insulation, and casting to form a blank. The special aluminum alloy prepared through the technology has the physical characteristics of high mechanical strength, high abrasion resistance, high fatigue resistance, high heat resistance, high gluing resistance, high saturability, high mosaicism to foreign matters, and the like, can effectively solve the seepage caused by the increased axial clearance because of the super-large shaft sleeve abrasion of a gear pump, can improve the service life and the output power of the gear pump, and makes the service life of the gear pump using the alloy be 1-3 times the service life of an original pump.

Owner:安徽省宏瑞泰达机械科技有限公司

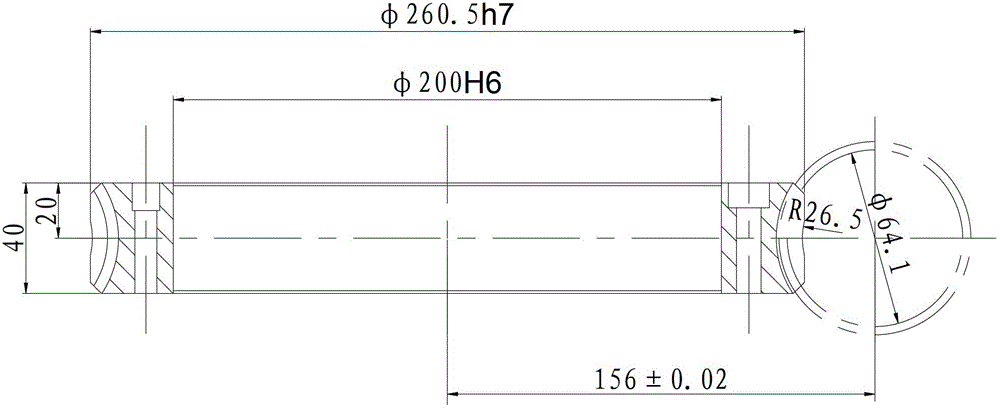

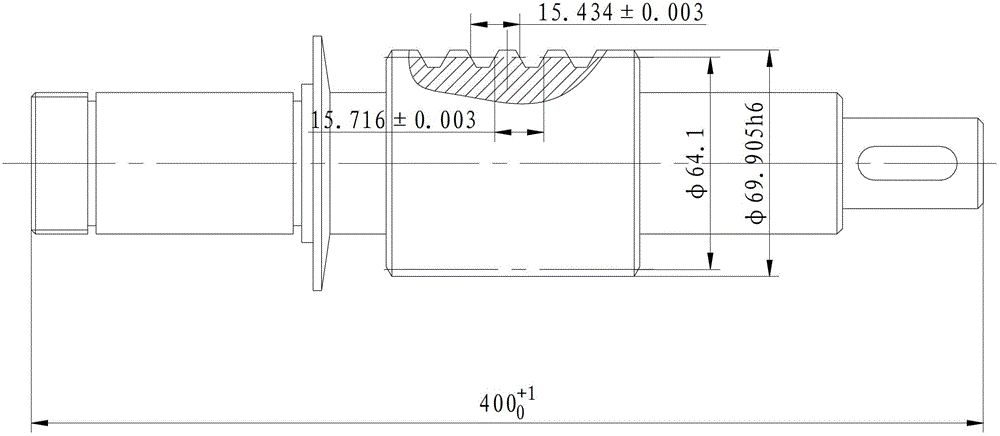

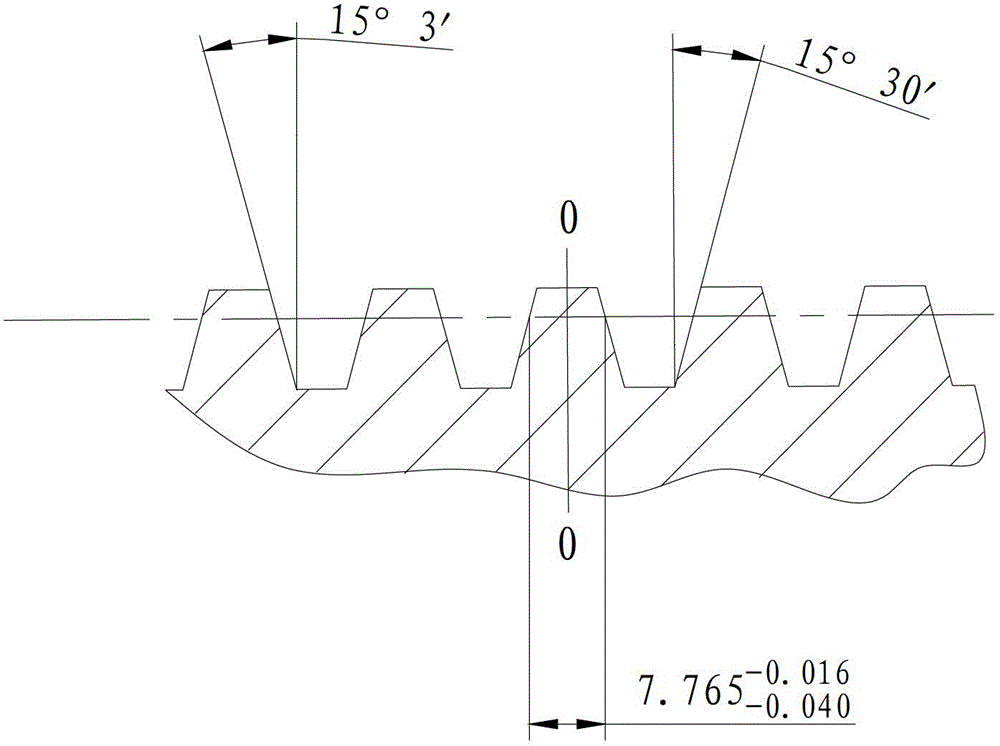

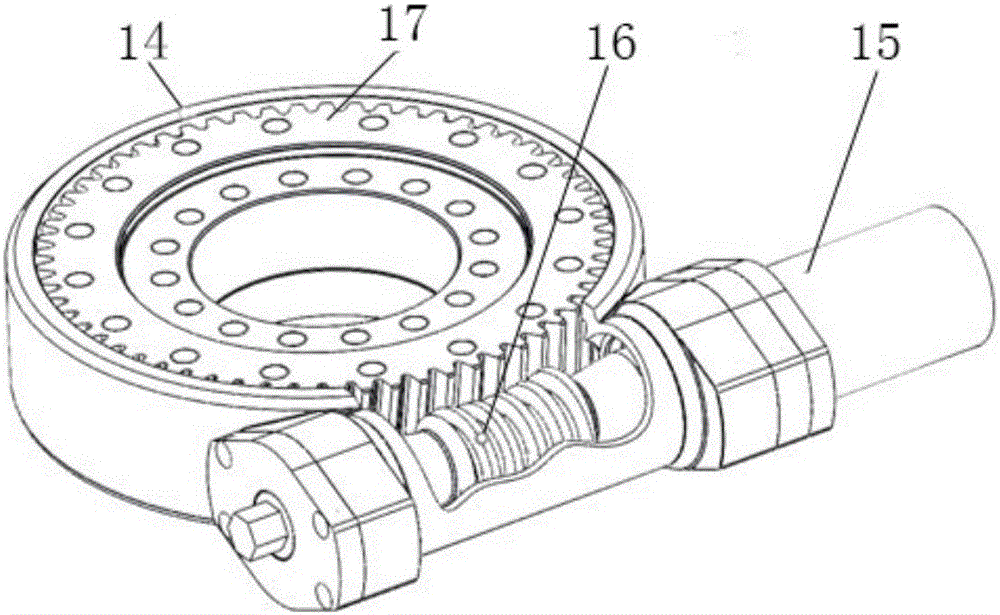

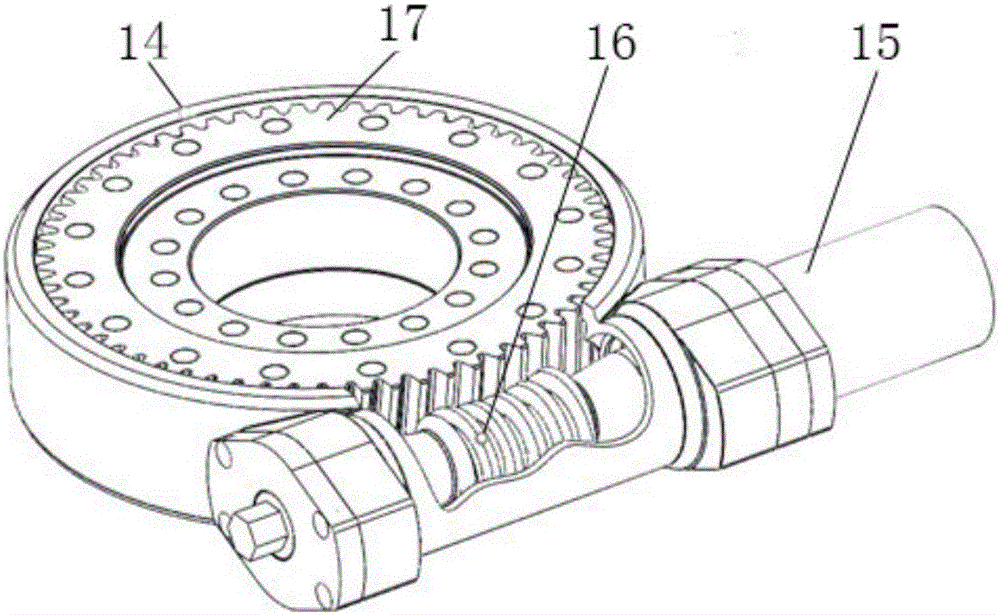

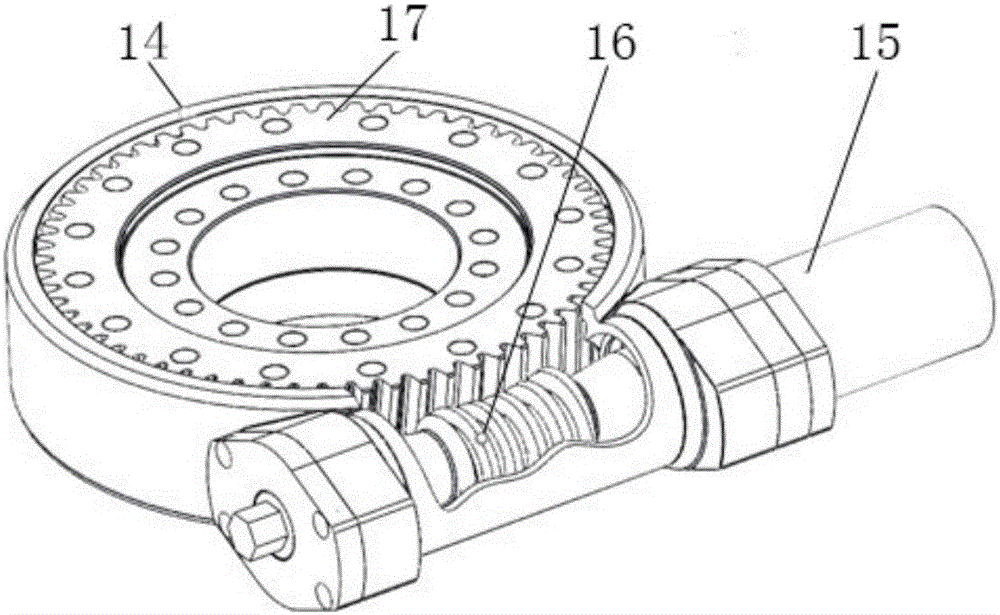

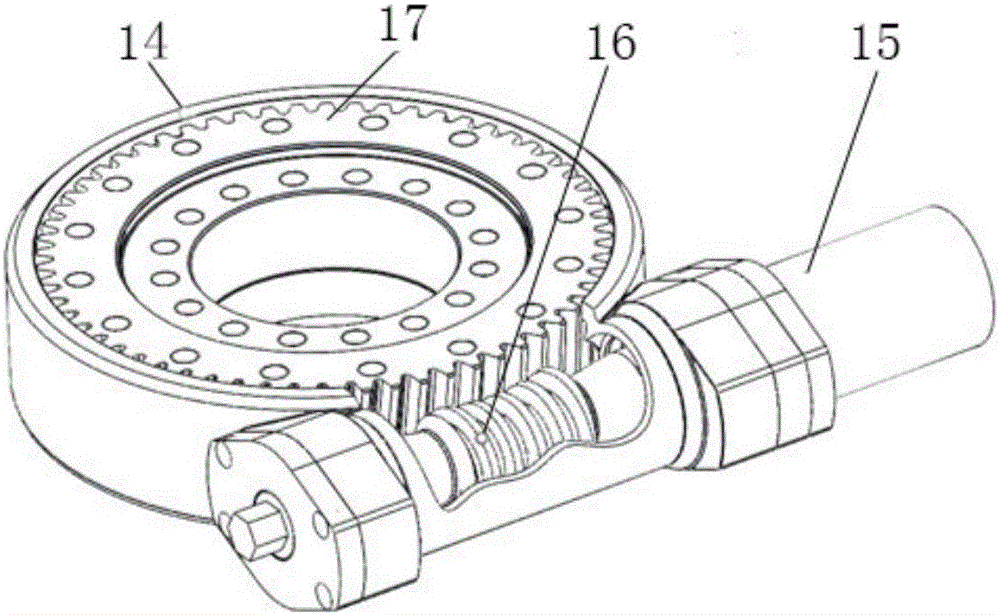

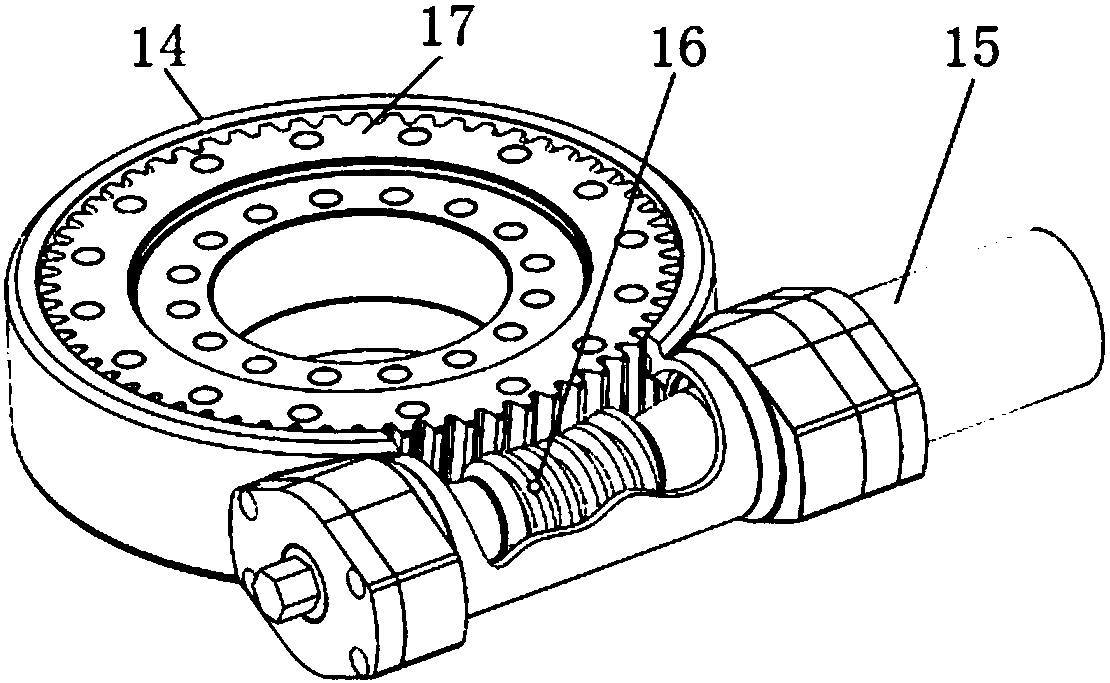

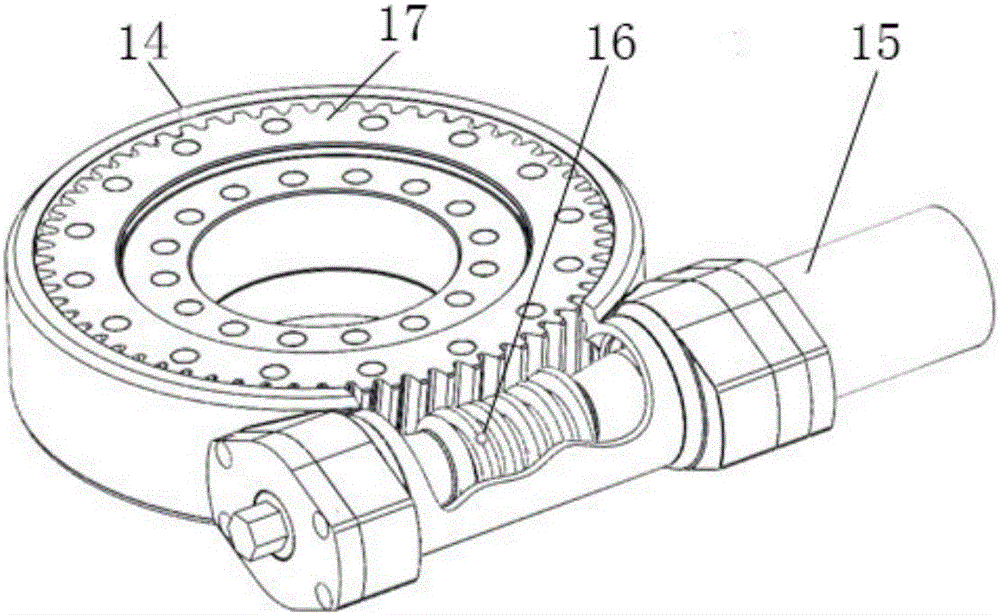

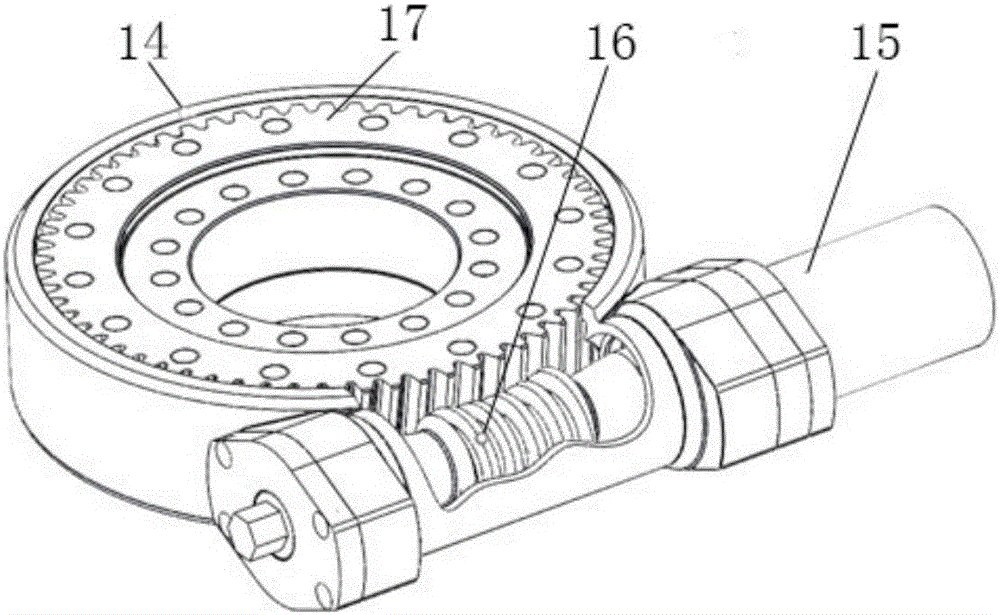

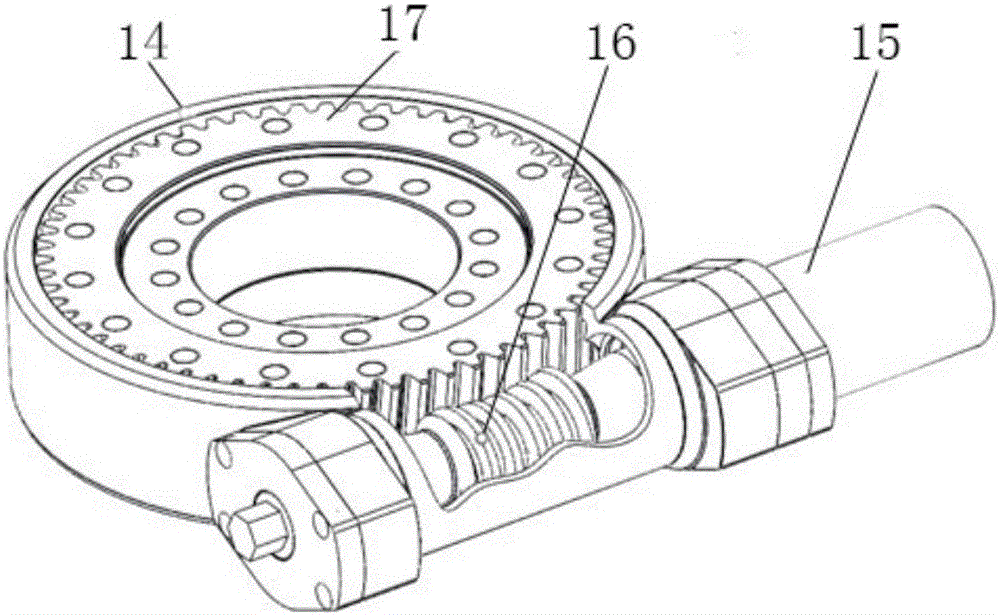

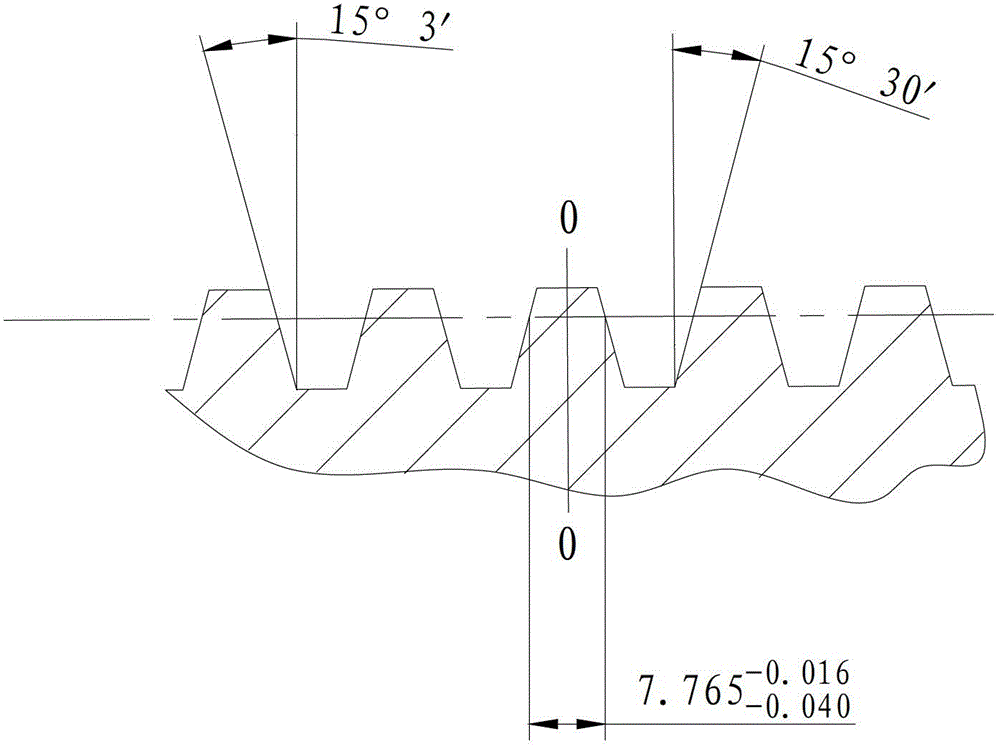

Machining method for worm gear tooth part

The invention relates to a machining method for a worm gear tooth part. The machining method comprises the steps that S1, arc machining is conducted on the worm gear tooth part; S2, the half angles of hobs and the center distance between the center of each hob and the center of a worm gear are calculated; S3, rough hobbing is conducted on the worm gear tooth part; S4, semi-finish hobbing is conducted on the worm gear tooth part; S5, finish hobbing is conducted on the worm gear tooth part; S6, grinding is conducted on the worm gear tooth part. The step S3, the step S4, the step S5 and the step S6 are all performed on a gear hobbing machine, and the same datum plane is utilized; the worm gear hubs used for gear hobbing conducted on the worm gear tooth part in the step S3, the step S4 and the step S5 are large-diameter worm gear hobs. The machining method has the advantages that a machined worm gear is high in accuracy and stable in transmission, contacting surfaces are easy to match, gear teeth are good in abrasion resistance, and bending strength is high.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

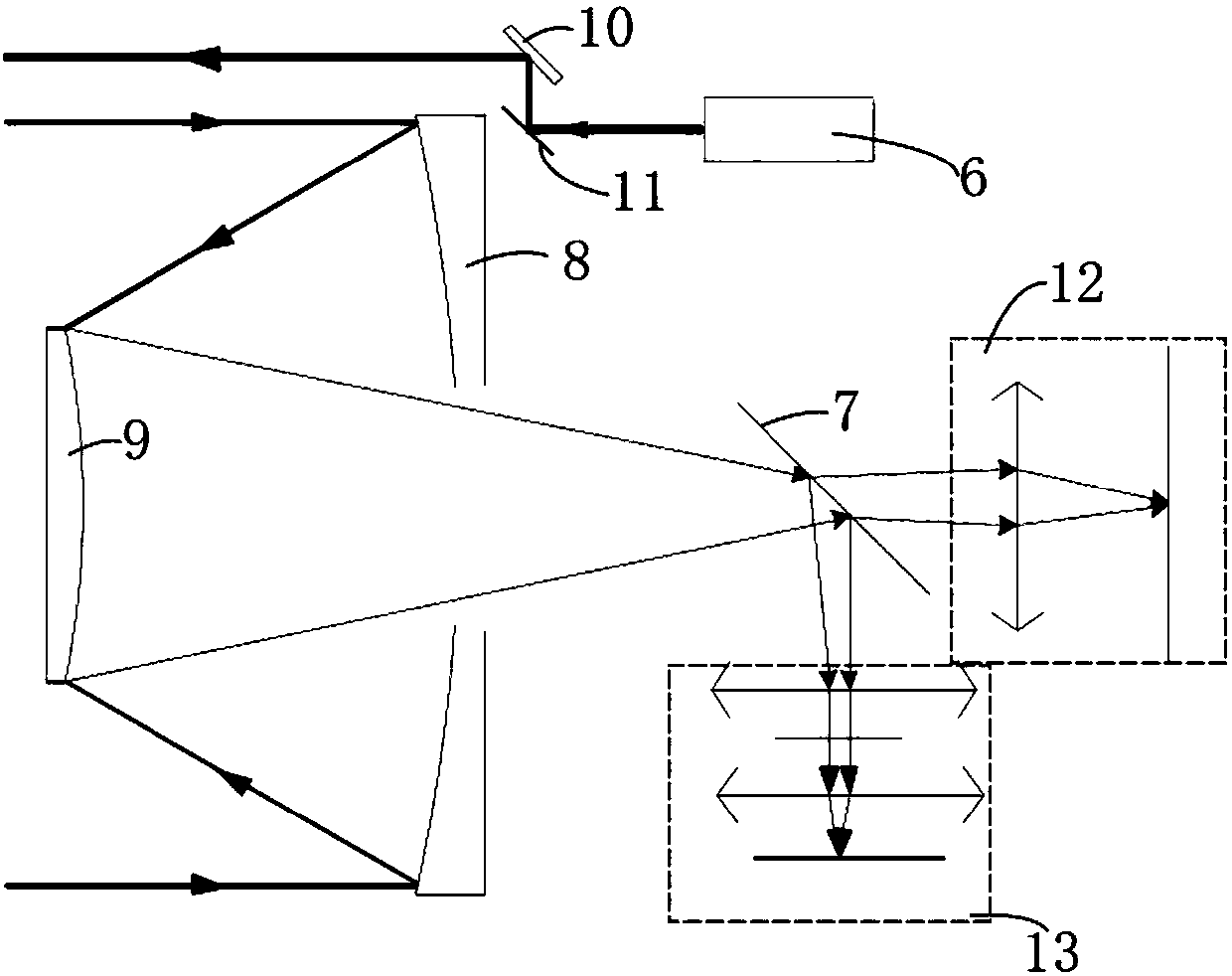

Full automatic cigarette conveying device

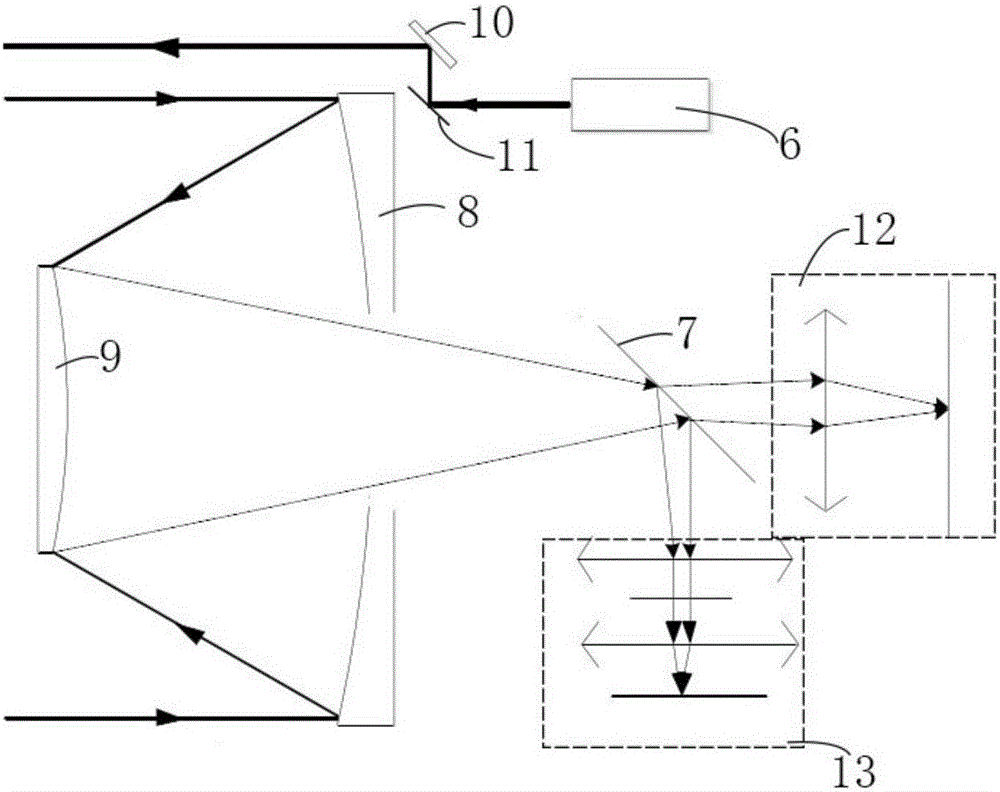

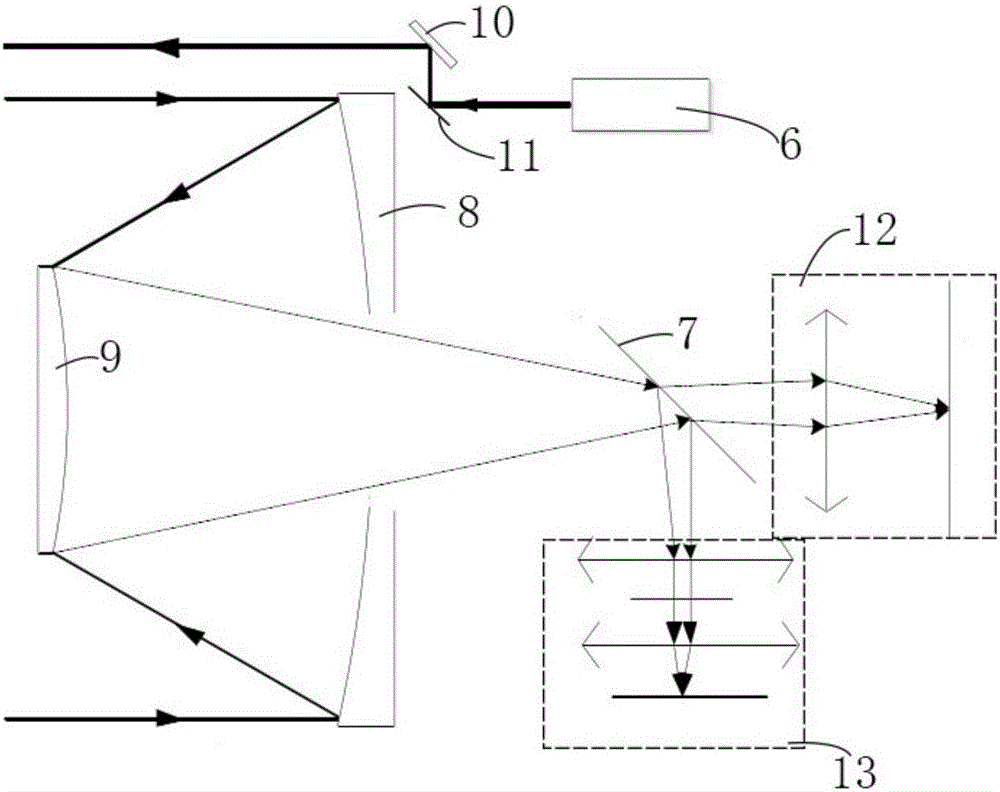

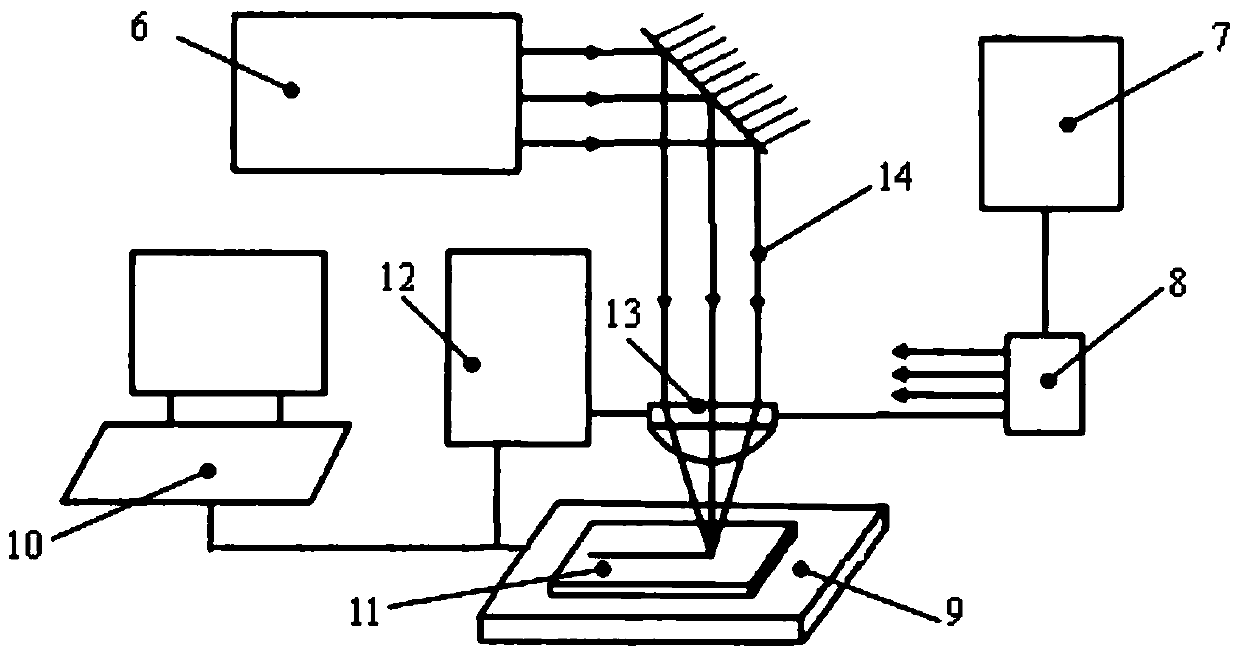

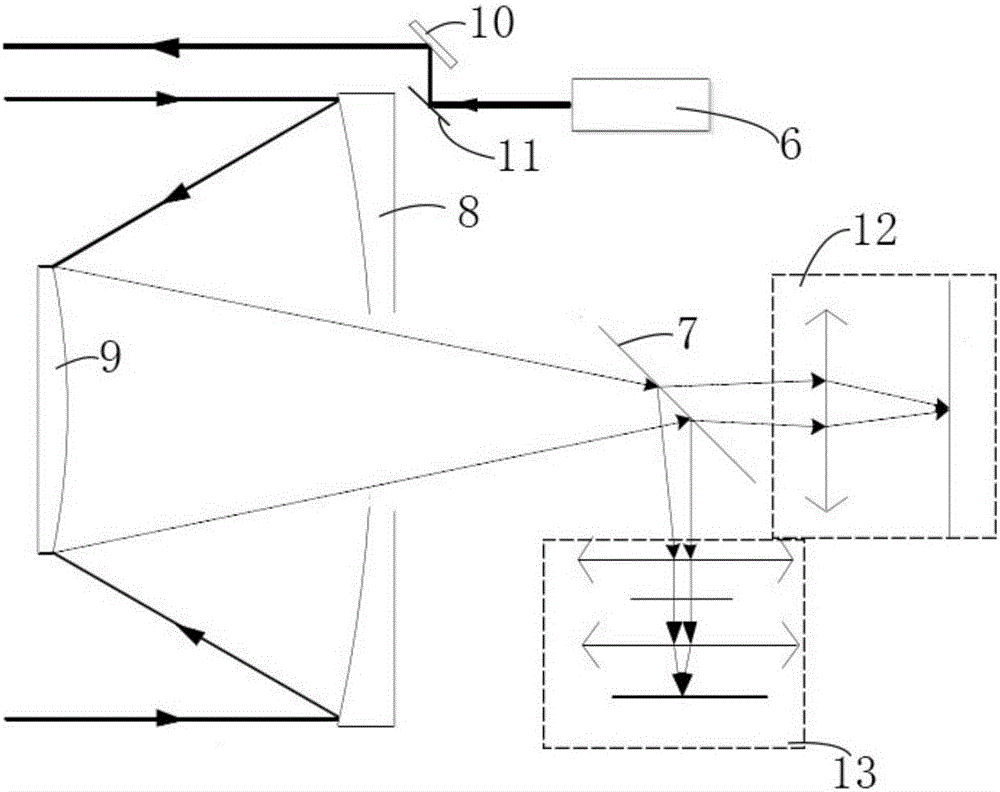

InactiveCN106257272AAdapt to different needsReduce volumeOptical rangefindersOptically investigating flaws/contaminationPackaging machineEngineering

The invention discloses a full automatic cigarette conveying device. The full automatic cigarette conveying device comprises a frame, the frame is provided with a conveyer belt, front and rear sides of the conveyer belt along a forward direction are respectively provided with an inlet blocking device and an outlet blocking device, a cigarette pushing device is arranged above the conveyer belt between the inlet blocking device and the outlet blocking device, a movement direction of the cigarette pushing device is perpendicular to a movement direction of the conveyer belt, the frame at the side of the conveyer belt is provided with a lifting-type cigarette receiving platform and the cigarette pushing device moves between the conveyer belt and the lifting-type cigarette receiving platform. The full automatic cigarette conveying device is a full automatic cigarette conveying and buffer storage device which has a compact structure, improves production efficiency, is installed between a packaging machine and a lifting machine and realizes automatic storage and release of cigarettes. The full automatic cigarette conveying device is used for cigarette automatic buffer storage and release.

Owner:吴桂广

Infrared remote control device realized based on Android system

InactiveCN106169238AAdjustable positionAdapt to different needsTelevision system detailsNon-electrical signal transmission systemsRemote controlEmbedded system

The invention discloses an infrared remote control device realized based on an Android system. The device comprises a processor and an infrared emission diode. The processor includes a plurality of pins, the pins are connected to the infrared emission diode, the processor is used for placing the pins at high level or low level successively according to a plurality of predetermined encoding ways respectively when receiving a test instruction so as to generate a series of encoded infrared remote control signals in one-to-one correspondence with the encoding ways, and emits the series of encoded infrared remote control signals continuously to the electronic device through the infrared emission diode, and the series of encoded infrared remote control signals include remote control signals that control the electronic device in terms of carrying out a plurality of different operations. The infrared remote control device provided by the invention is conducive to realizing automation of electronic device infrared performance testing.

Owner:吴桂广

Automatic package feeding machine for food film packing material packages

InactiveCN106428835AAdjustable positionAdapt to different needsPackagingControl systemEconomic benefits

The invention discloses an automatic package feeding machine for food film packing material packages. The machine comprises a feeding hopper set controlled by a photoelectric control system and capable of realizing adjustment of bulk material packages to single package conveying in sequence and automatically feeding to a preset station, a linear conveying device adjacent to a discharge port of the feeding hopper set, and a turntable disc, a synchronous arrangement set and an automatic package feeding set arranged below an output end of the linear conveying device from top to bottom. As the automatic bulk package feeding unit consisting of the feeding hopper set, the linear conveying device, the turntable set, the synchronous arrangement set and the automatic package feeding set is adopted, a traditional connected material package feeding mode is changed to single bulk package automatic feeding, the difficulties of feeding quality and efficiency caused by uncertainty of specifications, variety diversity and shape sizes of film packing material packages in industrial food production are solved, the production efficiency is improved by above 20% when guaranteeing the material package feeding quality, and the social and economic benefits are better.

Owner:吴桂广

Automatic control device using infrared sensing

InactiveCN106444851AAdjustable positionAdapt to different needsOptical detectionControl using feedbackAutomatic controlPower saving

The invention discloses an automatic control device using infrared sensing. The automatic control device includes a screen unit for controlling a screen switch, an infrared temperature sensing unit for detecting the temperature in front of the screen and sending the detected result as an electronic signal, and a control unit for receiving the electronic signal sent by the infrared temperature sensing unit and for performing the determination based on the electronic signal. According to the invention, before the user leaves the screen, the screen can automatically enter the screen protection state or screen standby state, therefore, the power-saving effect can be achieved, and the protection of the content displayed by the user screen is effectively guaranteed.

Owner:吴桂广

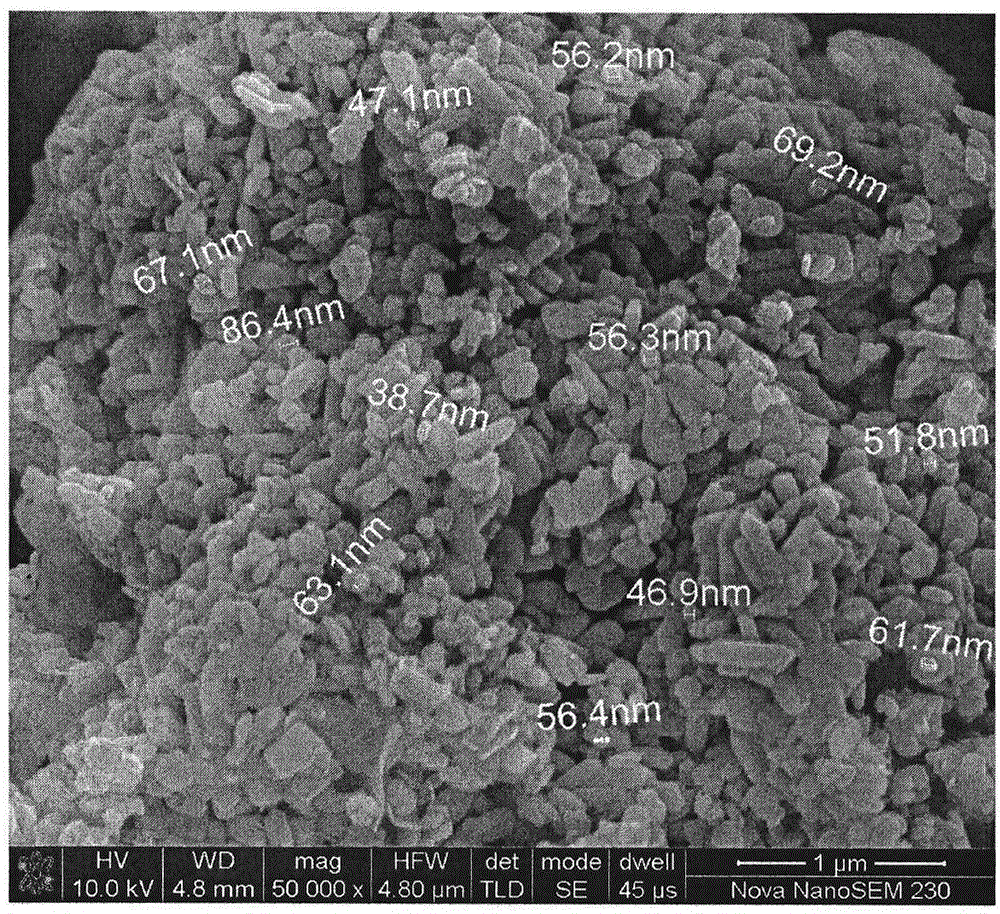

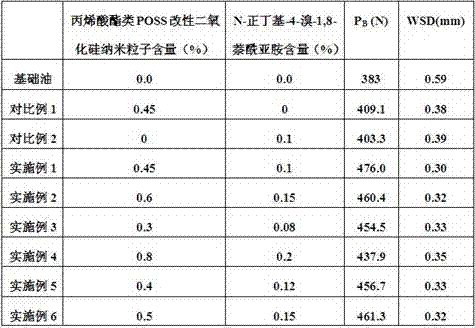

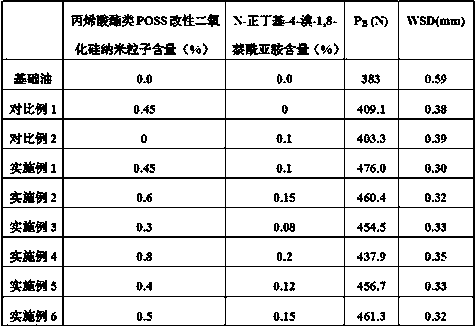

Acrylics POSS-modified silicon dioxide nanoparticle-containing lubricating oil and preparation method thereof

ActiveCN107164032AImprove carrying capacityImprove glue resistanceLubricant compositionBromineBase oil

The invention discloses acrylics POSS-modified silicon dioxide nanoparticle-containing lubricating oil and a preparation method thereof, and belongs to the technical field of lubricating oil. The acrylics POSS-modified silicon dioxide nanoparticle-containing lubricating oil is prepared from basic oil and an additive, wherein the additive is prepared from acrylics POSS-modified silicon dioxide nanoparticles and N-normal-butyl-4-bromine-1,8-naphthalimide. After the acrylics POSS-modified silicon dioxide nanoparticles and N-normal-butyl-4-bromine-1,8-naphthalimide are added into the basic oil, the anti-wear and friction-reducing performance is greatly improved, and the bearing performance of the lubricating oil is also improved. Furthermore, the acrylics POSS-modified silicon dioxide nanoparticles and N-normal-butyl-4-bromine-1,8-naphthalimide are easily dispersed in the basic oil, and no agglomeration phenomenon is caused.

Owner:山东沾化莱斯特石油化工有限公司

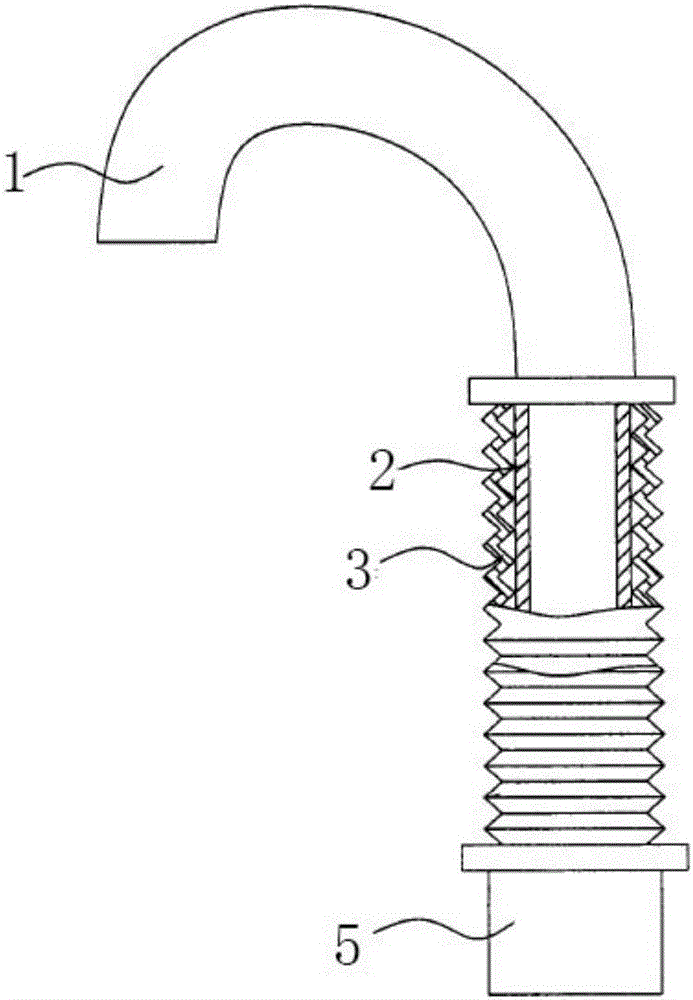

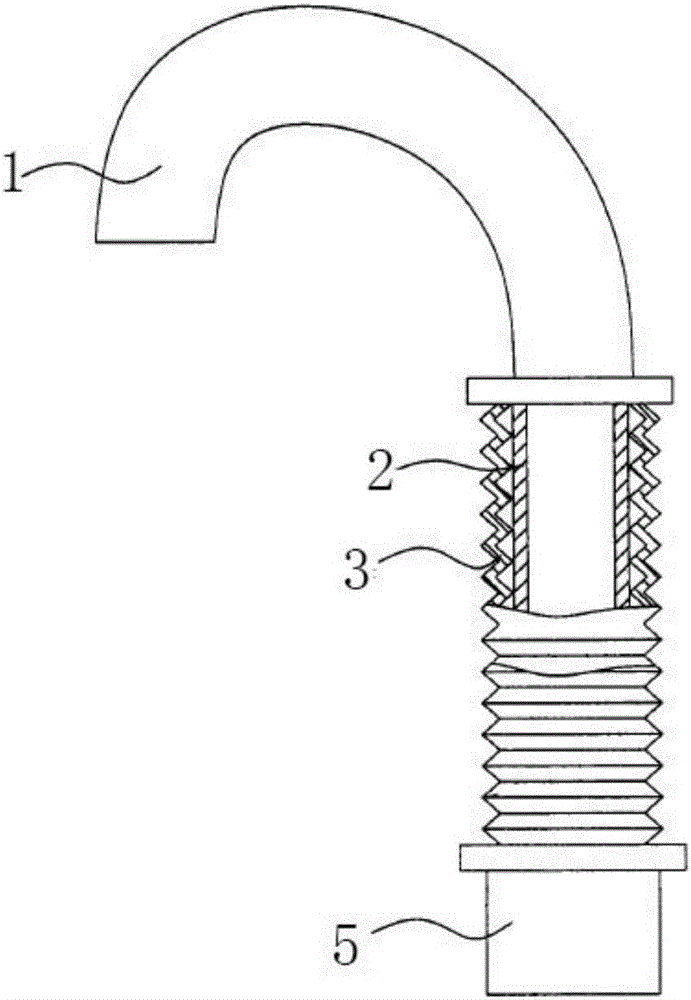

Automatic spraying device

The invention discloses an automatic spraying device. The automatic spraying device comprises a tank body, an emptying valve, a water spraying valve, a ball valve, a pressure gage, a water inlet valve, an air inlet valve and a safety valve; a connecting pipe of a water spraying pipe is installed in the bottom of the tank body, the emptying valve is installed below the tank body, and a connecting pipe of the emptying valve is welded to the tank body; the ball valve, the water inlet valve, the air inlet valve and the safety valve are welded to the tank body through connecting pipes respectively; the pressure gage is connected with the ball valve. The automatic spraying device is simple and reasonable in structure; pressure is applied to the tank body through an air compressor, the air pressure forces clear water to flow out of the water spraying valve, and the effect of automatic spraying is achieved; the ball valve and the pressure gage are mainly used for observing the pressure of the tank body, and the safety valve is used for relieving the pressure of the tank body under abnormal conditions. After use of the automatic spraying device is completed every time, remaining clear water can be drained off by switching on the emptying valve, and corrosion of the tank body can be prevented.

Owner:吴桂广

Manufacturing method of tin-phosphor-bronze alloy part with high wear resistance, temperature resistance and gluing resistance

InactiveCN110468302AImprove high temperature resistanceImprove glue resistanceElectric heatingBronze

The invention discloses a manufacturing method of a tin-phosphor-bronze alloy part with high wear resistance, temperature resistance and gluing resistance. The manufacturing method is characterized bypouring 100 kg of red copper into a furnace liner of an electric heating type "medium-frequency induction melting furnace" for melting for about 20 minutes; then adding fine tin in a ratio of 8-9%; then wrapping red phosphorus with tin foil paper and putting the wrapped red phosphorus into a copper solution in a ratio of 0.5-0.6% in five minutes; then putting the prepared pieces cut from 100 kg of red copper wires into the copper solution; and tightly compressing the red phosphorus and continuously smelting for 15 minutes, and then putting 100 kg of the red copper. The complete melting process only takes 48 minutes, and the pouring is finished through three centrifuges within 25 minutes. The tin-phosphor-bronze alloy part with high wear resistance, temperature resistance and gluing resistance has excellent mechanical and physical comprehensive properties and can resist high temperature of 800 DEG C or higher, the friction coefficient can exceed 0.00965, and the anti-gluing capabilityhas great breakthrough since no gluing phenomenon occurs at high speed and high temperature for 24 hours.

Owner:封安钰

Intelligent container system

InactiveCN106395229AAdjustable positionAdapt to different needsStorage devicesLogistics managementEngineering

The invention discloses an intelligent container system. An intelligent container comprises an intensive shuttle type belt conveyor conveying and storing zone in the overlook direction, a delivery-out temporary storing zone and a warehousing temporary storing zone are arranged on the two sides of the intensive shuttle type belt conveyor conveying and storing zone correspondingly, and a delivery-out opening and a warehousing opening are formed in the front side of the delivery-out temporary storing zone and the front side of the warehousing temporary storing zone correspondingly. A roadway machine shuttle road and a cargo handling and delivery-out zone are sequentially arranged in the front side of the intensive shuttle type belt conveyor conveying and storing zone. According to the intelligent container system, different measures are taken according to judgment of information including packet storing information of addressees, the sizes of packets, storage cabinet storing space conditions, user credit rating and the like, express packet storing and taking efficiency is improved by analyzing packet taking awareness of users, the express logistics process management level of a logistics company is improved, residents can get express packets rapidly and accurately, and the more successful express terminal receiving and dispatching service is achieved.

Owner:吴桂广

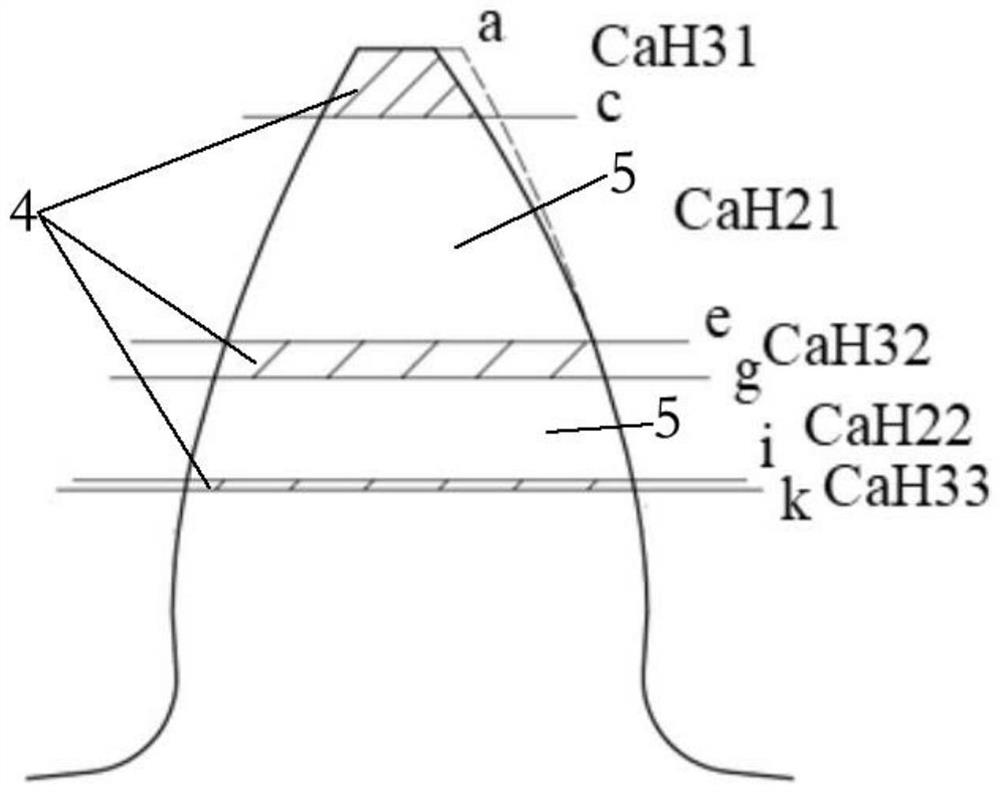

A face gear with layered structure and its realization method

ActiveCN104864067BHigh hardnessImprove wear resistancePortable liftingMetallic material coating processesDistribution characteristicEngineering

Owner:刘晓雁

Automatic cloth delivering and collecting device

InactiveCN106167191AAdjustable positionAdapt to different needsWebs handlingMechanical engineeringAutomatic tuning

Owner:吴桂广

Improved tin-phosphor bronze alloy manufacturing process

The invention relates to the field of tin-phosphor bronze alloy production, in particular to an improved tin-phosphor bronze alloy manufacturing process which comprises the following steps: step 1, red copper is poured into an electric heating furnace to be melted for a period of time; secondly, refined tin with the mass larger than 9% of the mass of the red copper and smaller than or equal to 14% of the mass of the red copper is doped into the electric heating furnace for smelting for a period of time; thirdly, red phosphorus with the mass larger than 0.6% of the mass of the red copper and smaller than or equal to 1.2% of the mass of the red copper is doped into the electric heating furnace, and smelting continues for a period of time; 4, red copper is poured into the electric heating furnace, smelting is conducted for a period of time, and then a blank is formed through pouring; and fifthly, the blank is extruded to form the compact tin-phosphor bronze alloy. When the technical scheme is adopted, the wear resistance, the high temperature resistance and the bonding resistance of the tin-phosphor bronze alloy can be improved.

Owner:封安钰

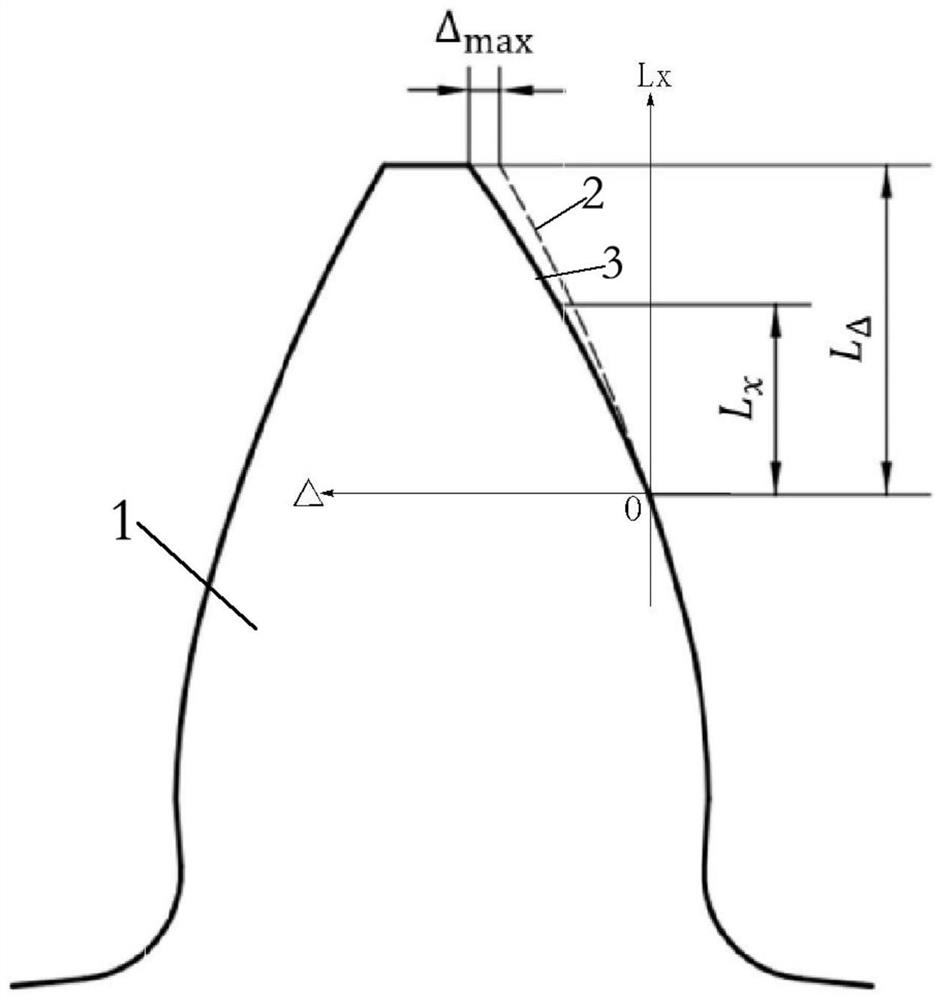

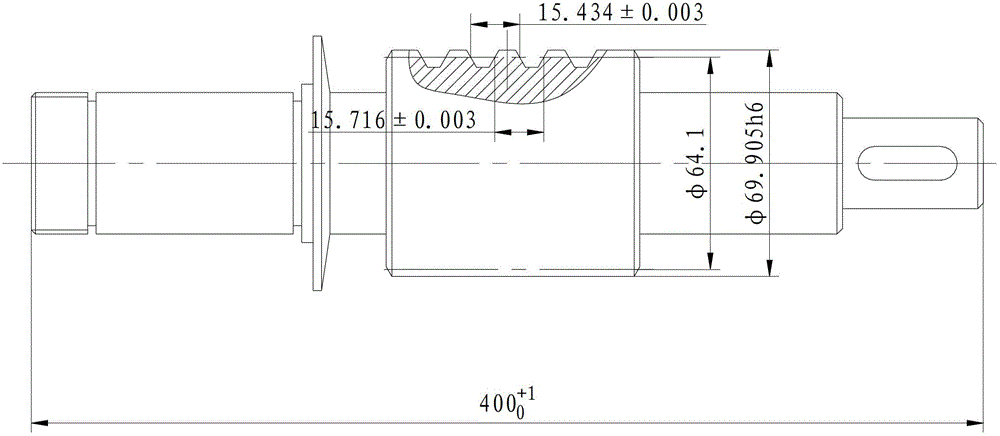

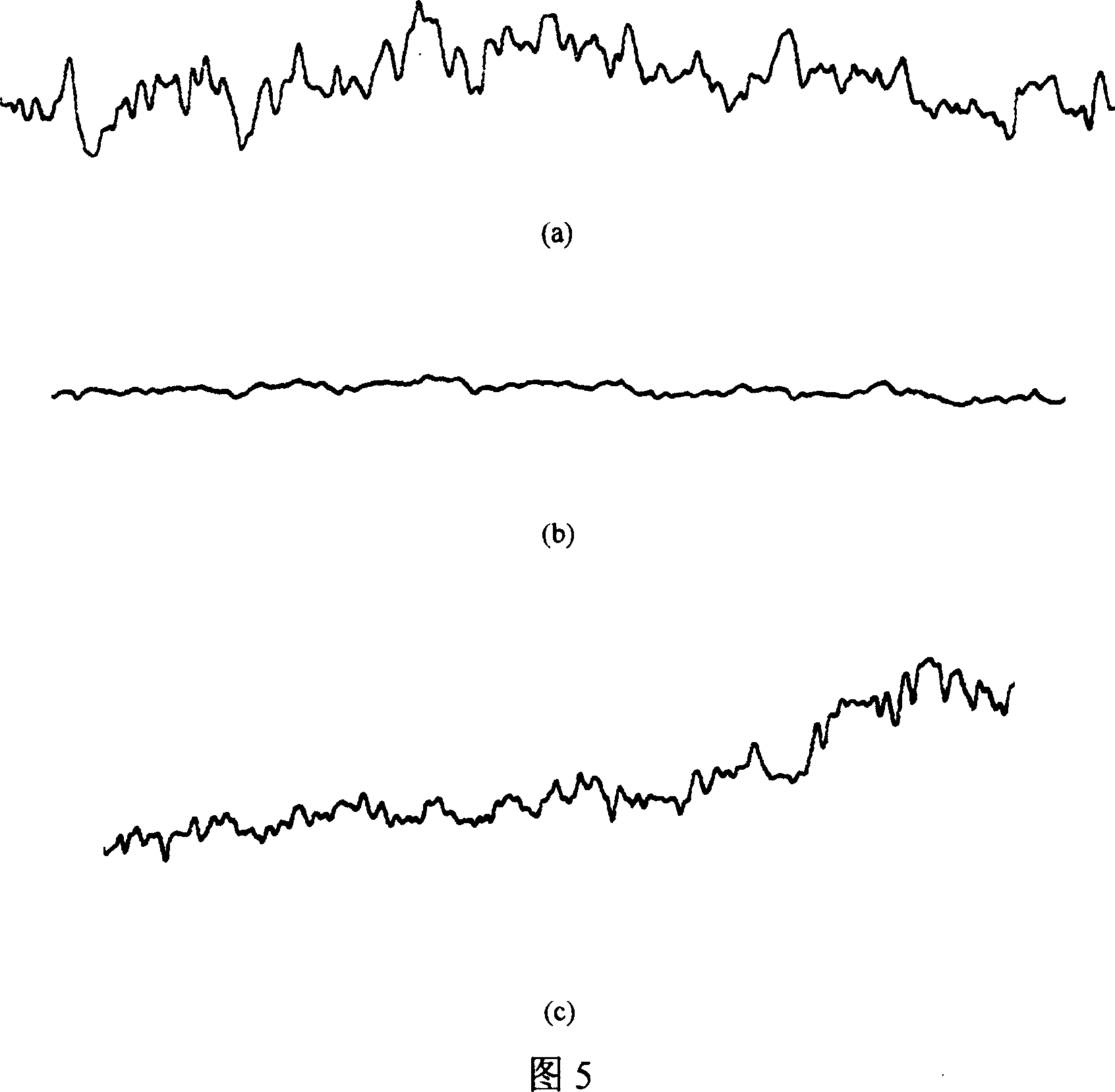

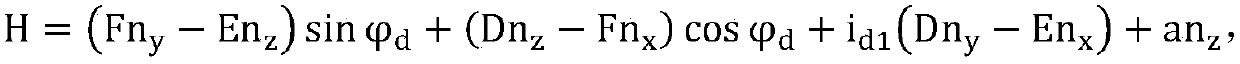

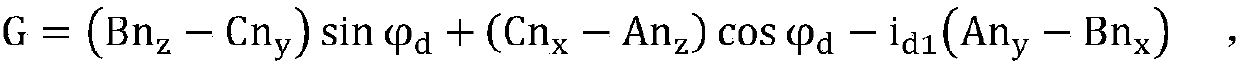

A gear modification method for reducing the contact temperature of gear tooth surfaces

ActiveCN113464624BImprove glue resistanceReduce mutationGeometric CADPortable liftingRectangular coordinatesGear wheel

The invention relates to the technical field of gear modification, in particular to a gear modification method for reducing the contact temperature of the gear tooth surface, comprising the following steps: S1: selecting the three-tooth meshing area closest to the tooth tip and the corresponding two-tooth meshing area The tooth profile of the tooth profile to be modified is used as the tooth profile to be modified; S2: The plane rectangular coordinate system (O-L X Δ), the plane Cartesian coordinate system (O-L X Δ) of the ordinate axis L X Parallel to the radial direction of the gear, the abscissa axis of the plane rectangular coordinate system is the modification amount Δ; S3: Calculate the maximum modification amount Δ of the end point relatively close to the tooth tip on the tooth profile to be modified max ; S4: Select a modification curve, the equation of the modification curve is: In the above formula, L Δ It is the ordinate of the end point relatively close to the tooth tip on the tooth profile to be modified. The invention can reduce the maximum tooth surface contact temperature when the gear teeth are meshed, and reduce or even eliminate the sudden change of the load in each meshing area of the meshing gear.

Owner:UNIV OF JINAN +1

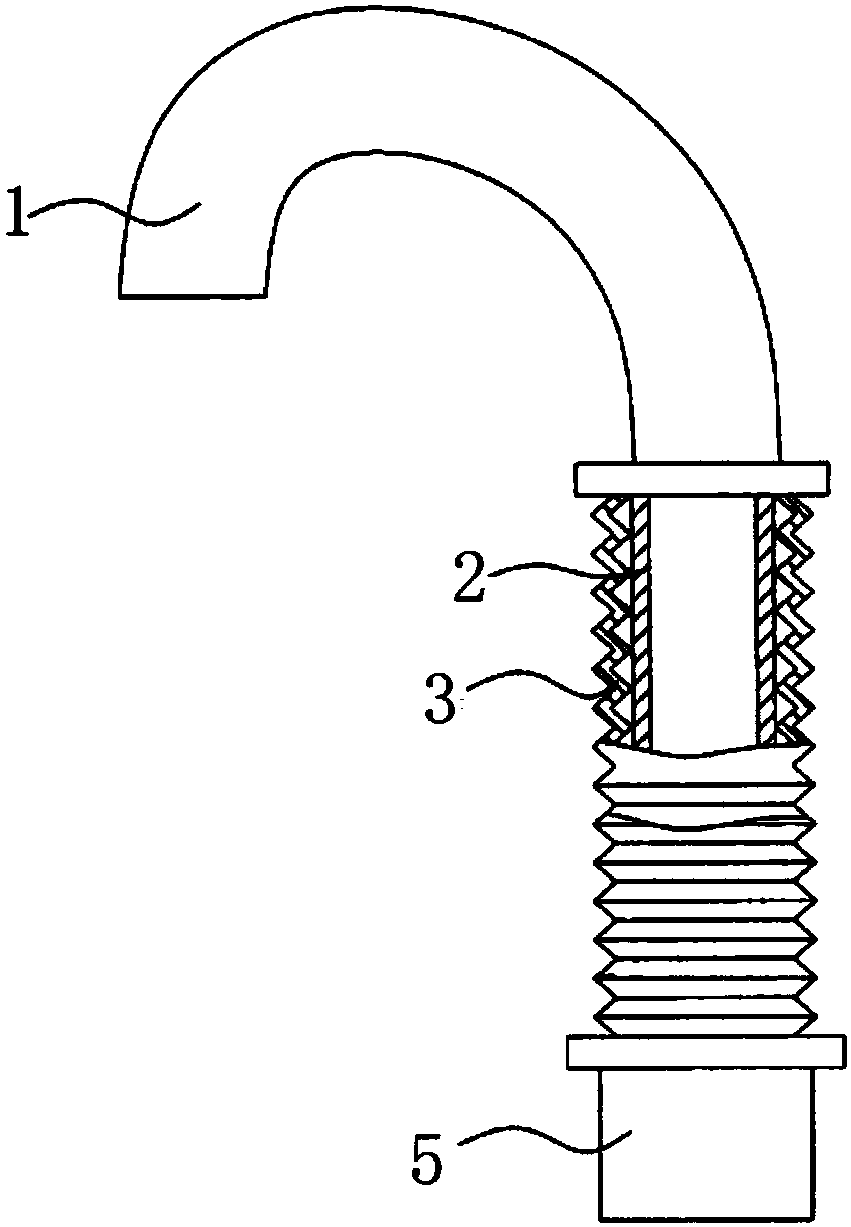

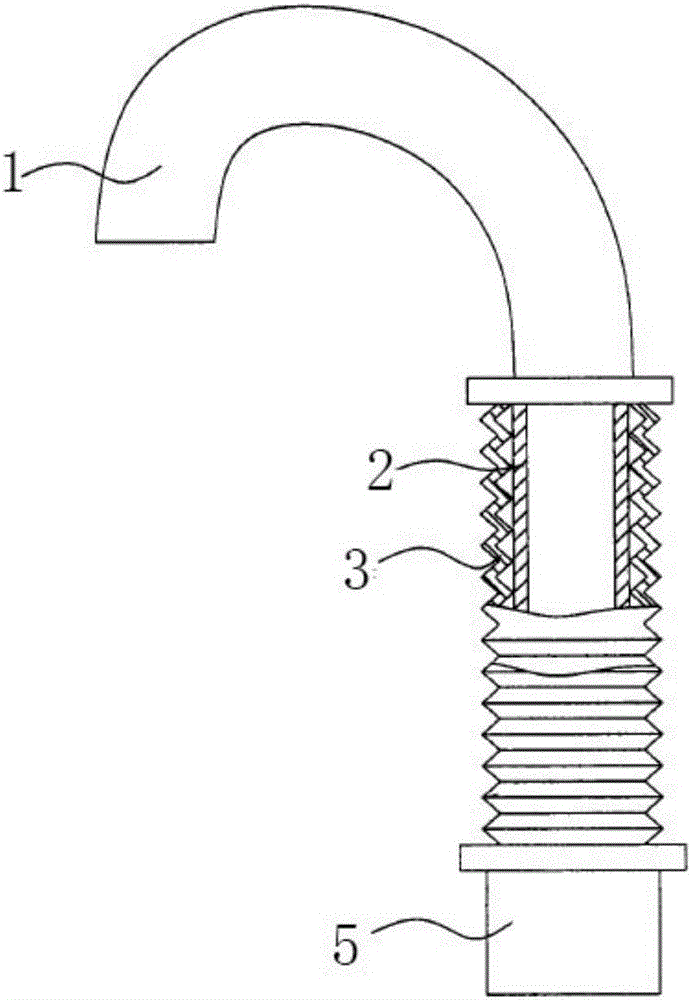

Medical automatic cleaning machine

InactiveCN106180034AAdapt to different needsAdjustable positionUsing reradiationCleaning using liquidsEngineeringCleansing Agents

The invention discloses a medical automatic cleaning machine. The machine comprises an outer casing, an upper cover, a material basket and a water inlet system, wherein the material basket is arranged in the outer casing; the upper cover is arranged above the material basket; and the water inlet system is connected with the outer casing and is used for supplying water to the inside of the outer casing so as to clean components. With the machine, the problem of secondary pollution caused by the fact that materials are taken by the aid of clamping tools for cleaning machines is solved. Liquids are supplied to the inside of the cleaning machine by the aid of an automatic liquid supply system. The liquids can be discharged automatically, conveniently and quickly.

Owner:吴桂广

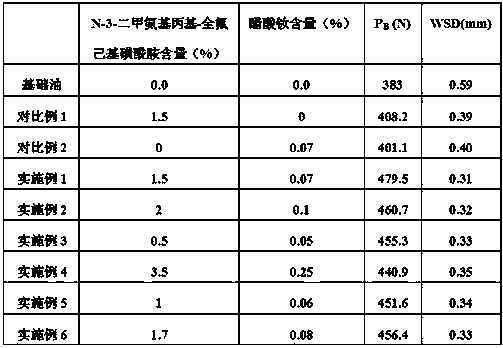

A kind of lubricating oil containing n-3-dimethylaminopropyl-perfluorohexylsulfonamide and its preparation method

ActiveCN107164033BImprove carrying capacityImprove glue resistanceLubricant compositionBase oilOrganic chemistry

The invention discloses N-3-dimethylamino propyl-perfluorocarbon sulfonamide-containing lubricating oil and a preparation method thereof, and belongs to the technical field of lubricating oil. The N-3-dimethylamino propyl-perfluorocarbon sulfonamide-containing lubricating oil is prepared from basic oil and an additive, wherein the additive is prepared from N-3-dimethylamino propyl-perfluorocarbon sulfonamide and neodymium acetate. After the N-3-dimethylamino propyl-perfluorocarbon sulfonamide and neodymium acetate are added into the basic oil, the anti-wear and friction-reducing performance is greatly improved, the antiscuffing capacity of a friction pair is enhanced, and the bearing performance of the lubricating oil is also improved. Furthermore, N-3-dimethylamino propyl-perfluorocarbon sulfonamide and neodymium acetate are easily dispersed in the basic oil, and no agglomeration phenomenon is caused.

Owner:山东沾化莱斯特石油化工有限公司

Manufacturing method for mine vehicle axle wheel reductor planetary gear

ActiveCN102979884BGood contact fatigue strengthImprove reliabilityGear lubrication/coolingPortable liftingGear wheelReduction drive

The invention relates to a mine vehicle axle wheel reductor planetary gear and a manufacture method thereof. The manufacture method comprises the following processing steps of: (1) forging to obtain a gear ring; (2) roughly turning; (3) carrying out preheat treatment; (4) finely turning; (5) carrying out ultrasonic flaw detection; (6) hobbing; (7) boring a plurality of oilholes in the wall of a planet wheel inner hole in the middle of the gear ring along the radial direction of the planet wheel inner hole; (8) carburizing for heat treatment; (9) performing plain grinding on two end faces of the gear ring to the required size and then grinding the planet wheel inner hole of the gear ring to the required size; (10) grinding the gear; (11) carrying out magnetic powder inspection; (12) strengthening shot peening at gear root; and (13) carrying out manganese phosphating. The planetary gear produced by adopting the manufacture method, disclosed by the invention has the advantages that the contact fatigue strength is better, the reliability is greatly enhanced and the service life is greatly prolonged; and according to the manufacture method provided by the invention, shot peening strengthening is adopted in processing the gear root, and the stress state of the gear root is changed, so that the gear root bending strength of the planetary gear is remarkably enhanced, the strength of the planetary gear is enhanced and the service life of the planetary gear is prolonged.

Owner:WUXI WEIFU CHINA ITAL GEAR

Machining method of worm gear tooth

The invention relates to a machining method for a worm gear tooth part. The machining method comprises the steps that S1, arc machining is conducted on the worm gear tooth part; S2, the half angles of hobs and the center distance between the center of each hob and the center of a worm gear are calculated; S3, rough hobbing is conducted on the worm gear tooth part; S4, semi-finish hobbing is conducted on the worm gear tooth part; S5, finish hobbing is conducted on the worm gear tooth part; S6, grinding is conducted on the worm gear tooth part. The step S3, the step S4, the step S5 and the step S6 are all performed on a gear hobbing machine, and the same datum plane is utilized; the worm gear hubs used for gear hobbing conducted on the worm gear tooth part in the step S3, the step S4 and the step S5 are large-diameter worm gear hobs. The machining method has the advantages that a machined worm gear is high in accuracy and stable in transmission, contacting surfaces are easy to match, gear teeth are good in abrasion resistance, and bending strength is high.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

A kind of lubricating oil containing perfluorooctanesulfonyl fluoride and its preparation method

The invention discloses lubricating oil containing perfluoro-1-octanesulfonyl fluoride and a preparation method thereof, and belongs to the technical field of lubricating oil. The lubricating oil containing perfluoro-1-octanesulfonyl fluoride is composed of base oil and additives. The additives are composed of perfluoro-1-octanesulfonyl fluoride and bismuth iso-octoate. After perfluoro-1-octanesulfonyl fluoride and bismuth iso-octoate are added into base oil, antiwear and antifriction performance is greatly enhanced, antiscuffing capacity of friction pairs is raised, and load-carrying capacity of the lubricating oil is also improved. In addition, perfluoro-1-octanesulfonyl fluoride and bismuth iso-octoate are easy to disperse in base oil and there will be no coagulation phenomenon.

Owner:山东沾化莱斯特石油化工有限公司

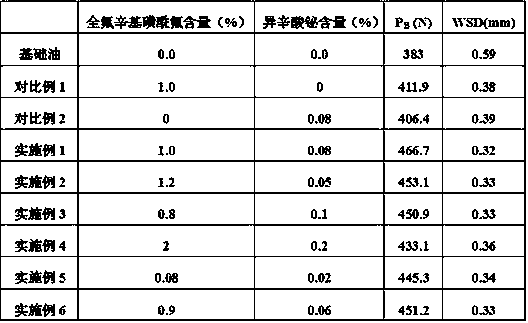

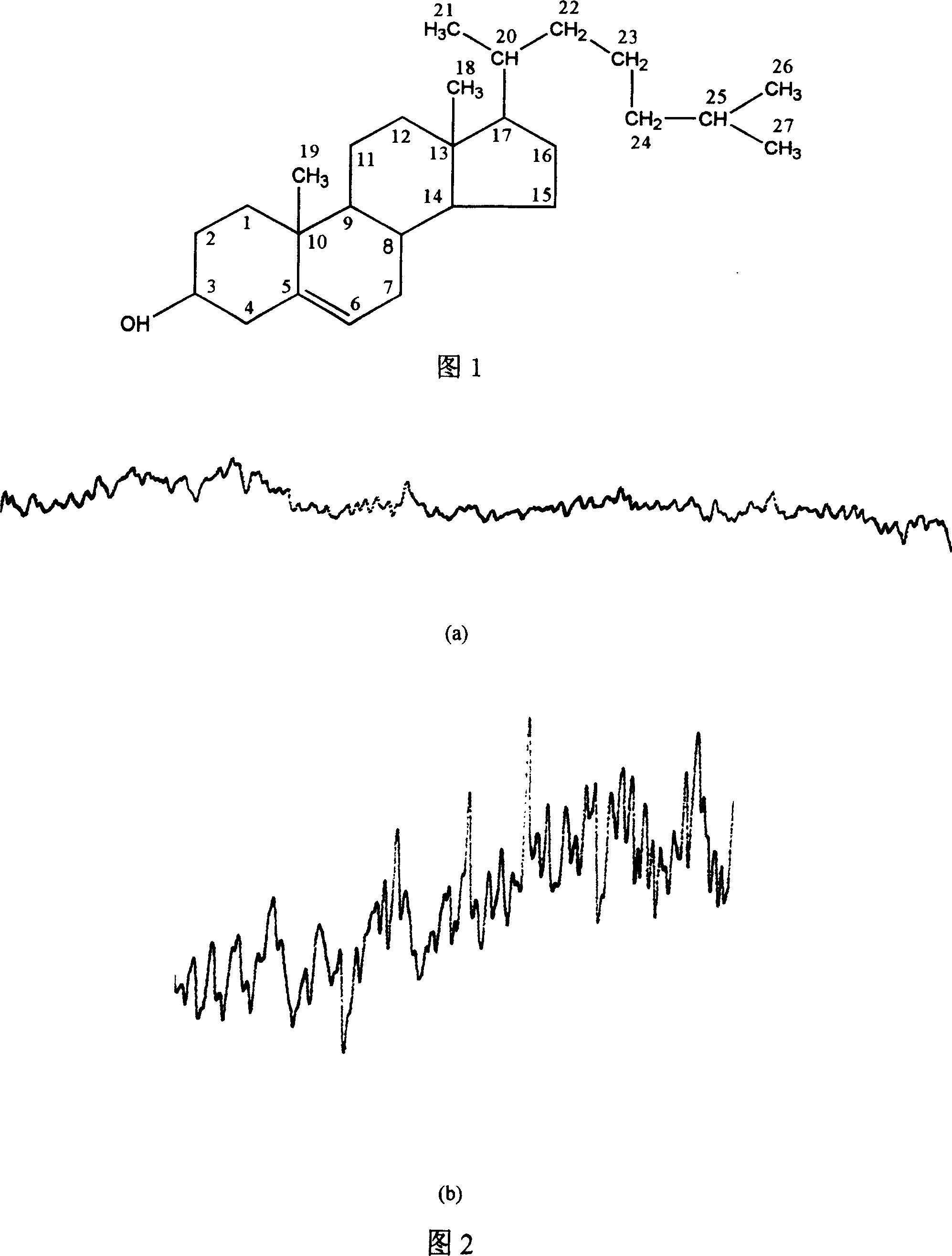

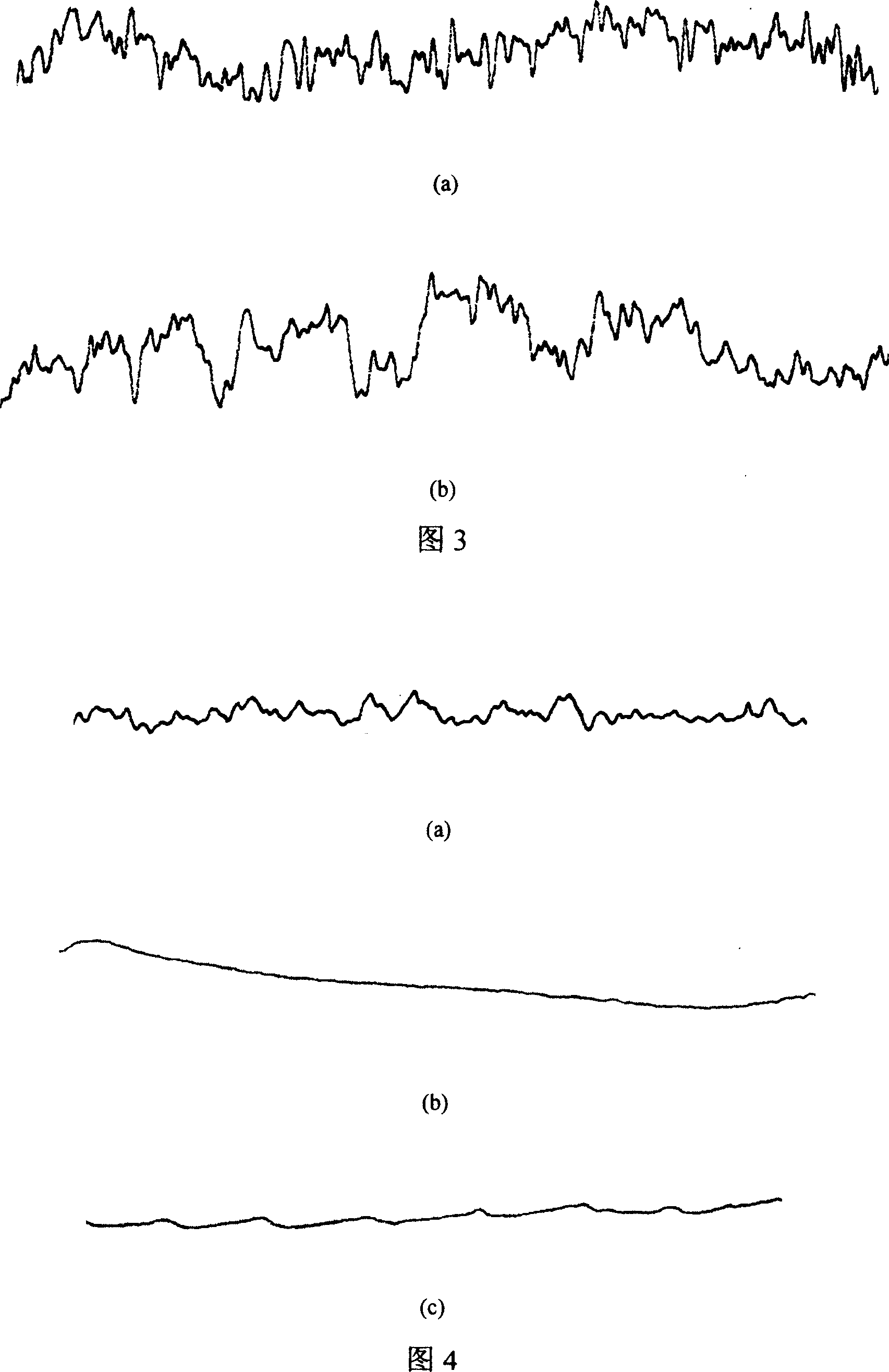

Process for preparing lubricating oil containing cholesterol

InactiveCN1321171CImprove glue resistanceImprove friction and wear resistanceAdditivesCholesterolWear resistance

The present invention discloses preparation process of lubricating oil containing cholesterol. Cholesterol in 0.05-4.0 wt% as additive is added into lubricating oil through heating to 80-90 deg c and stirring, before being cooled to normal temperature. Cholesterol may be added into lubricating oil easily without pollution to reduce friction and raise wear resistance of gears, worms, rolling bearings, sliding bearing and other mechanical parts, and raise the gluing resistance of the friction pair.

Owner:ZHEJIANG UNIV

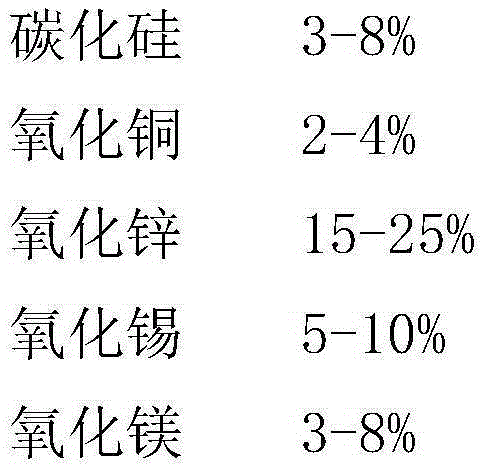

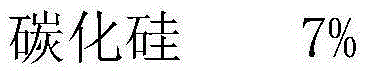

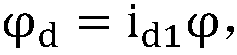

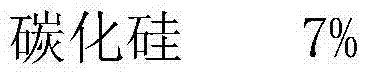

Aluminum alloy composition and its preparation process

The invention discloses an aluminum alloy composition and a preparation process thereof, and relates to the technical field of profiles. The preparation process comprises the following steps: 1) putting aluminum into a smelting furnace for smelting, and when the smelting temperature inside the smelting furnace is 680+10 DEG C, adding magnesium oxide and stannic oxide for further smelting; 2) when the smelting temperature is 1600+10 DEG C, adding copper oxide, zinc oxide and silicon carbide, when the temperature is 750+10 DEG C, stopping heating, and preserving heat for 1 hour; 3) analyzing the smelted material by adopting spectral analysis, performing refining treatment at 740+10 DEG C after the material is qualified in the analysis, and further adjusting the smelting if the material is not qualified in the analysis; and 4) standing for 10-20 minutes after the refining is accomplished, putting the material into a heat preservation electric furnace of 720+10 DEG C for heat preservation, and finally casting to form blanks. Due to addition of the silicon carbide component, the problem of leakage caused by directional gap increase as a gear pump shaft sleeve is excessively abraded is effectively solved, and the service life and the output power of a gear pump are prolonged and improved, that is, the service life is 1-3 times longer than that of a conventional pump.

Owner:ANHUI HUAXING METAL

Packaging assembly control system

InactiveCN106200690AAdjustable positionAdapt to different needsOptical detectionPackaging automatic controlControl systemManufacturing engineering

The invention discloses a packaging assembly control system. The system comprises a pack, an external surface and a removable outer packaging component, wherein the pack possesses a main body of a container limitedly used for receiving a candy product; the external surface is used for displaying a non-character class design; the removable outer packaging component is arranged surrounding the main body of the pack; and the outer packaging component is mainly non-transparent and includes character class product information.

Owner:吴桂广

Aluminum alloy composition and preparation process thereof

The invention discloses an aluminum alloy composition and a preparation process thereof, and relates to the technical field of profiles. The preparation process comprises the following steps: 1) putting aluminum into a smelting furnace for smelting, and when the smelting temperature inside the smelting furnace is 680+10 DEG C, adding magnesium oxide and stannic oxide for further smelting; 2) when the smelting temperature is 1600+10 DEG C, adding copper oxide, zinc oxide and silicon carbide, when the temperature is 750+10 DEG C, stopping heating, and preserving heat for 1 hour; 3) analyzing the smelted material by adopting spectral analysis, performing refining treatment at 740+10 DEG C after the material is qualified in the analysis, and further adjusting the smelting if the material is not qualified in the analysis; and 4) standing for 10-20 minutes after the refining is accomplished, putting the material into a heat preservation electric furnace of 720+10 DEG C for heat preservation, and finally casting to form blanks. Due to addition of the silicon carbide component, the problem of leakage caused by directional gap increase as a gear pump shaft sleeve is excessively abraded is effectively solved, and the service life and the output power of a gear pump are prolonged and improved, that is, the service life is 1-3 times longer than that of a conventional pump.

Owner:ANHUI HUAXING METAL

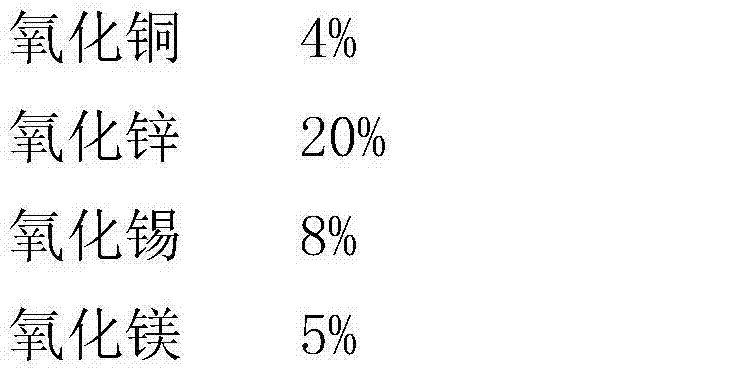

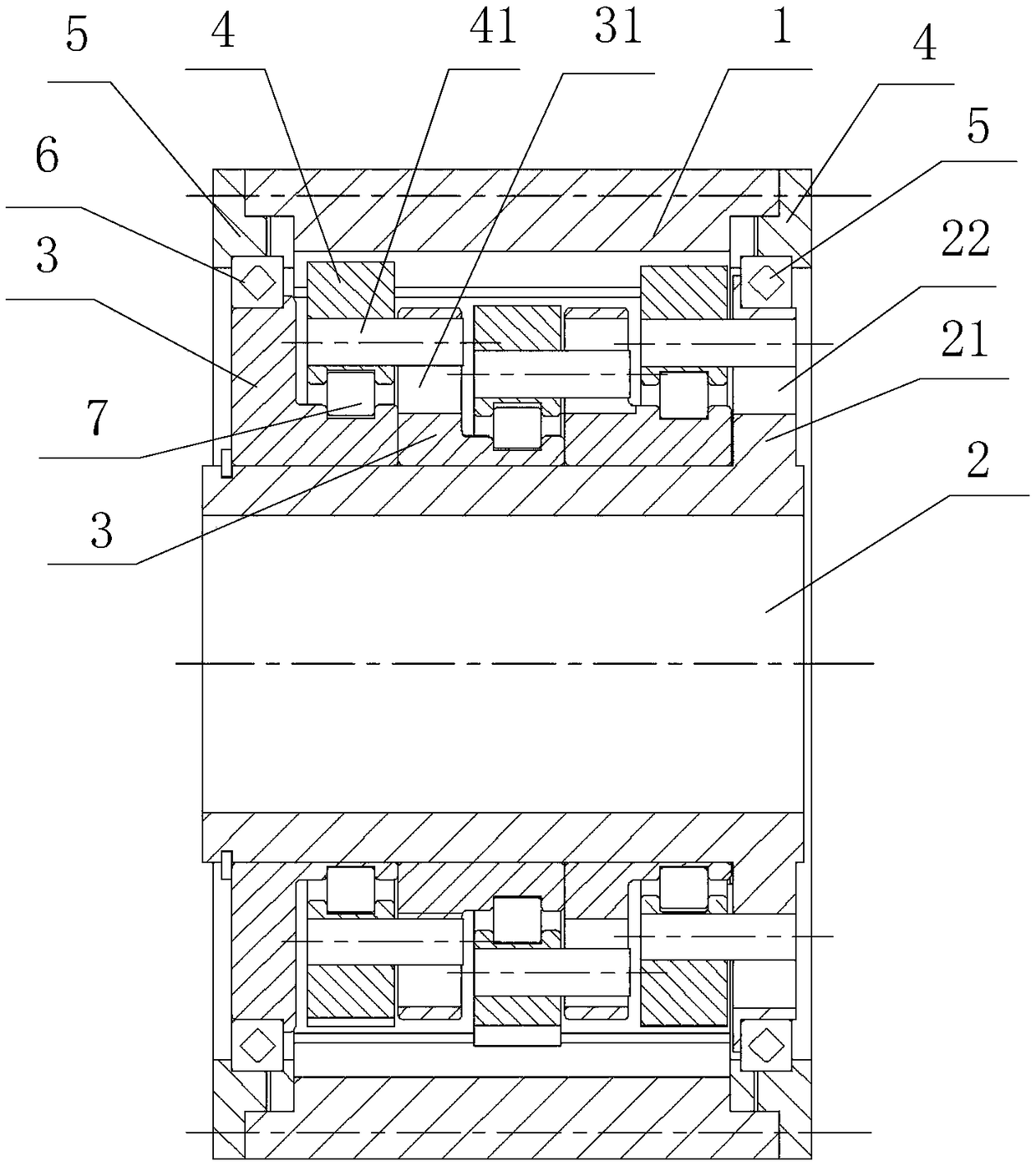

Multi-tooth-difference annular plate cascading speed reducer

The invention provides a multi-tooth-difference annular plate cascading speed reducer. The multi-tooth-difference annular plate cascading speed reducer comprises a central shaft, an inner gear and atleast two stages of transmission units connected in series; each stage of the transmission unit comprises a bearing force taking frame and an annular plate swinging wheel, the central shaft is sleevedwith the bearing force taking frames of the all stages of the transmission units, each stage of the annular plate swinging wheel is provided with an outer gear and multiple pin shafts, and the all stages of the annular plate swinging wheels mesh with the same inner gear; multi-tooth-difference cycloidal gear meshing is adopted as the meshing mode; power is transferred to the bearing force takingframe of the next-stage transmission unit through the pin shafts of the last-stage transmission unit, and the current-stage bearing force taking frame acquires rotating power from the last-stage transmission unit and drives the current-stage annular plate swinging wheel to eccentrically rotate; and the final-stage annular plate swinging wheel transfers power to the central shaft through the pin shafts. According to the multi-tooth-difference annular plate cascading speed reducer, assembling is easy, the structural rigidity is high, the multiple stages of the annular plate swinging wheels sharethe inner gear, and the movement transferring precision is higher; and structural arrangement is compact, the rigidity is higher than that of a general cycloidal-pin wheel speed reducer, and the impact resistance and the overload capacity are both improved.

Owner:CISDI RES & DEV CO LTD

A method for strengthening the super-lubricating surface of high-speed gear-like graphite carbon film

ActiveCN103469217BImprove friction and wear performanceImprove transmission efficiencySurface finishCarbon film

The invention relates to a super-lubricated surface strengthening method of a graphite-like carbon film for a high-speed gear. The method comprises the following steps: firstly, sequentially carrying out shot blasting, micro-jetting and fluid polishing pre-treatment on the surface of the gear to enable the surface smoothness of the gear to be less than 0.2 micron; then, by adopting an unbalanced magnetron sputtering composite target technology, introducing elements such as Y and Ta into a graphite-like carbon film preparation technology to prepare a graphite-like carbon film with ultralow friction coefficient on the surface of the gear, namely carrying out sputter cleaning on the surface of a base metal 1; and sequentially preparing a Cr transitional layer 3, a Cr / C gradient layer 4 and a graphite-like composite work layer 5 with ultralow friction coefficient on a fluid polishing surface layer 2. The method provided by the invention solves the problem that a solid lubricating film of the high-speed gear is short in service life, and the vibrating noise of the high-speed gear is effectively reduced. The vibrating noise of a transmission gear by adopting the technology is reduced by 10-15%, so that the method provides a novel technical path for reducing the vibrating noise of the gear.

Owner:CSIC NO 12 RES INST

A kind of lubricating oil containing acrylate poss modified silica nanoparticles and preparation method thereof

ActiveCN107164032BImprove carrying capacityImprove glue resistanceLubricant compositionImideAcrylate ester

The invention discloses acrylics POSS-modified silicon dioxide nanoparticle-containing lubricating oil and a preparation method thereof, and belongs to the technical field of lubricating oil. The acrylics POSS-modified silicon dioxide nanoparticle-containing lubricating oil is prepared from basic oil and an additive, wherein the additive is prepared from acrylics POSS-modified silicon dioxide nanoparticles and N-normal-butyl-4-bromine-1,8-naphthalimide. After the acrylics POSS-modified silicon dioxide nanoparticles and N-normal-butyl-4-bromine-1,8-naphthalimide are added into the basic oil, the anti-wear and friction-reducing performance is greatly improved, and the bearing performance of the lubricating oil is also improved. Furthermore, the acrylics POSS-modified silicon dioxide nanoparticles and N-normal-butyl-4-bromine-1,8-naphthalimide are easily dispersed in the basic oil, and no agglomeration phenomenon is caused.

Owner:山东沾化莱斯特石油化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com