Aluminum alloy composition and preparation process thereof

A composition and aluminum alloy technology, applied in the field of profiles, can solve the problems of reducing the service life and output power of high gear pumps, increasing the cost of use, etc., to improve service life and output power, solve leakage, and high wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

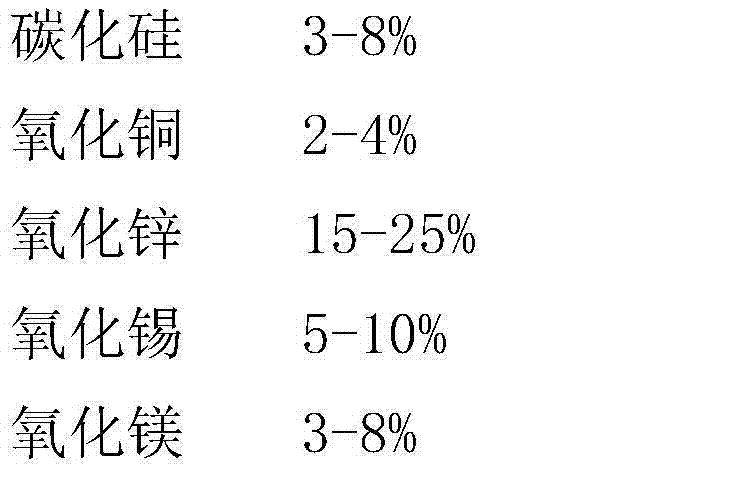

[0019] An aluminum alloy composition is composed of the following components in mass percentage:

[0020]

[0021] The balance is aluminum and unavoidable impurities.

[0022] 1) Put the aluminum into the furnace for smelting, when the melting temperature in the furnace reaches 680℃+10℃, add magnesium oxide and tin oxide and then smelt;

[0023] 2) When the melting temperature reaches 1600°C+10°C, add copper oxide, zinc oxide and silicon carbide, and when the temperature reaches 750°C+10°C, stop heating and keep warm for 1 hour;

[0024] 3) Spectral analysis is used to analyze the smelted materials. After the analysis is qualified, the refining treatment is carried out at a temperature of 740°C+10°C. If the analysis fails, the smelting is adjusted;

[0025] 4) After the refining is completed, let it stand for 10-20 minutes, put it into a heat preservation electric furnace at 720°C+10°C for heat preservation, and finally cast it into a billet.

Embodiment 2

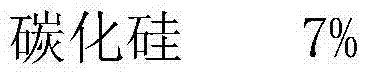

[0027] An aluminum alloy composition is composed of the following components in mass percentage:

[0028]

[0029] The balance is aluminum and unavoidable impurities.

[0030] 1) Put the aluminum into the furnace for smelting, when the melting temperature in the furnace reaches 680℃+10℃, add magnesium oxide and tin oxide and then smelt;

[0031] 2) When the melting temperature reaches 1600°C+10°C, add copper oxide, zinc oxide and silicon carbide, and when the temperature reaches 750°C+10°C, stop heating and keep warm for 1 hour;

[0032] 3) Spectral analysis is used to analyze the smelted materials. After the analysis is qualified, the refining treatment is carried out at a temperature of 740°C+10°C. If the analysis fails, the smelting is adjusted;

[0033] 4) After the refining is completed, let it stand for 10-20 minutes, put it into a heat preservation electric furnace at 720°C+10°C for heat preservation, and finally cast it into a billet.

Embodiment 3

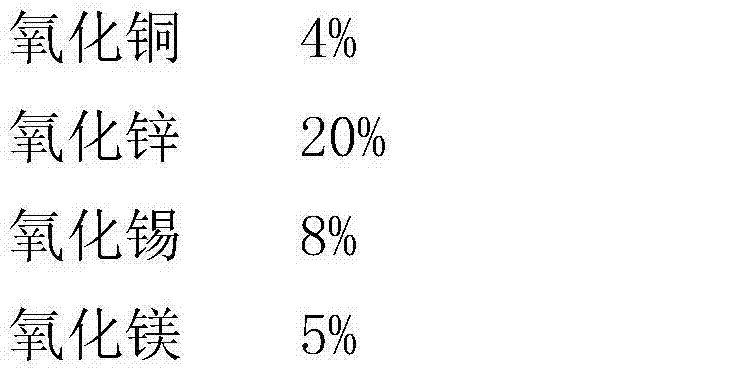

[0035] An aluminum alloy composition is composed of the following components in mass percentage:

[0036]

[0037]

[0038] The balance is aluminum and unavoidable impurities.

[0039] 1) Put the aluminum into the furnace for smelting, when the melting temperature in the furnace reaches 680℃+10℃, add magnesium oxide and tin oxide and then smelt;

[0040] 2) When the melting temperature reaches 1600°C+10°C, add copper oxide, zinc oxide and silicon carbide, and when the temperature reaches 750°C+10°C, stop heating and keep warm for 1 hour;

[0041] 3) Spectral analysis is used to analyze the smelted materials. After the analysis is qualified, the refining treatment is carried out at a temperature of 740°C+10°C. If the analysis fails, the smelting is adjusted;

[0042] 4) After the refining is completed, let it stand for 10-20 minutes, put it into a heat preservation electric furnace at 720°C+10°C for heat preservation, and finally cast it into a billet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com