Special aluminum alloy preparation technology

An aluminum alloy and special technology, applied in the field of special aluminum alloy preparation process, can solve the problems of reducing the service life and output power of high gear pumps, increasing the cost of use, etc., to improve the service life and output power, solve leakage, high The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0012] A special aluminum alloy preparation process, its process steps are as follows,

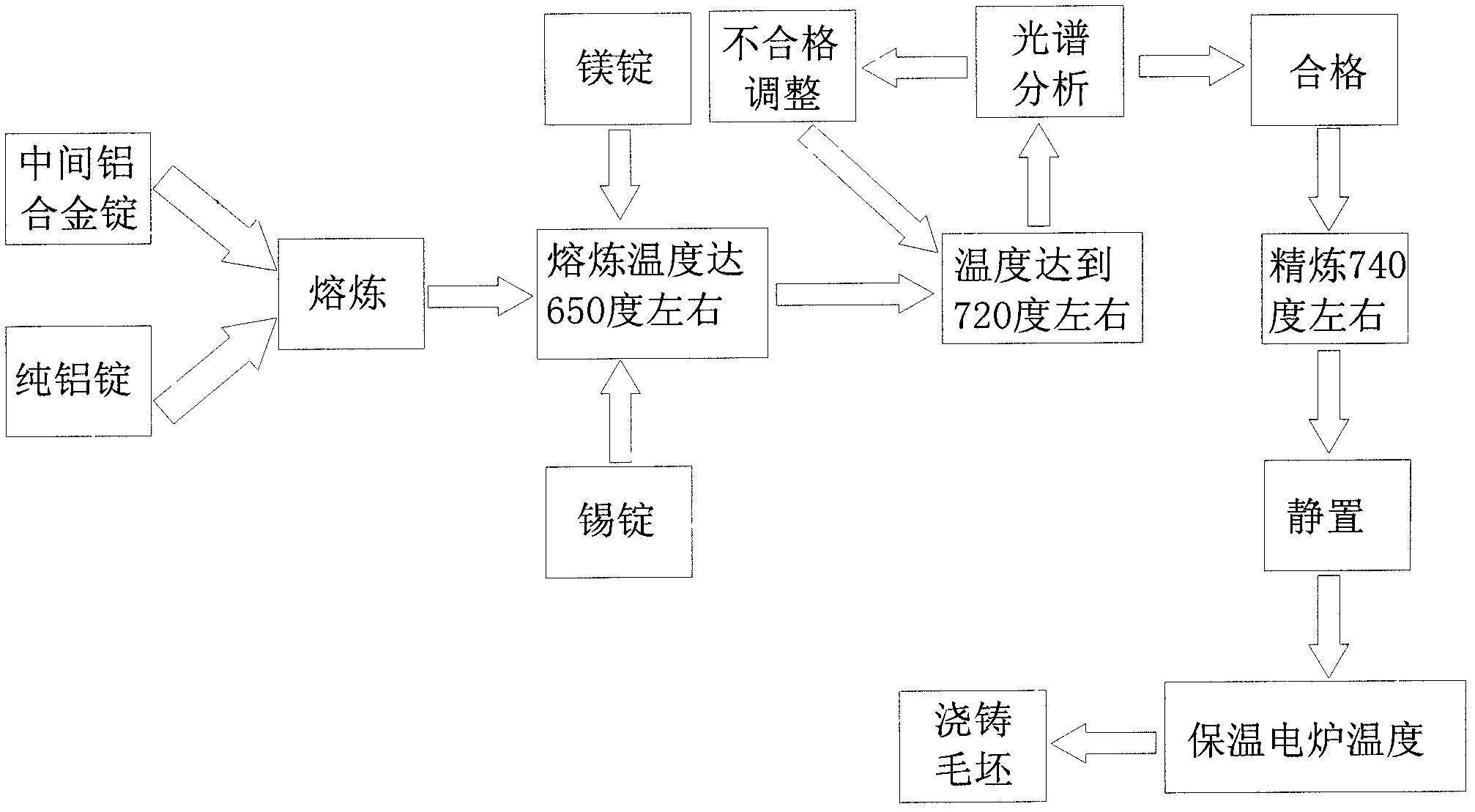

[0013] Such as figure 1 As shown, first put pure aluminum ingots and intermediate aluminum alloy ingots into the furnace for smelting, when the melting temperature in the furnace reaches 650°C±10°C, add magnesium ingots and tin ingots and then smelt, when the melting temperature reaches 720°C±10°C ℃, use spectral analysis to analyze the smelted material, and then carry out refining treatment at a temperature of 740°C±10°C after the analysis is qualified. If the analysis is unqualified, adjust the smelting. The heat preservation electric furnace is used for heat preservation, and the temperature of the heat preservation electric furnace is controlled at 720°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com