Machining method for worm gear tooth part

A processing method and worm gear technology, applied in the field of mechanical parts processing, can solve problems such as time-consuming, low production efficiency, and production difficulties, and achieve improved anti-gluing ability and wear resistance, good force bearing, and high bending strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the invention content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

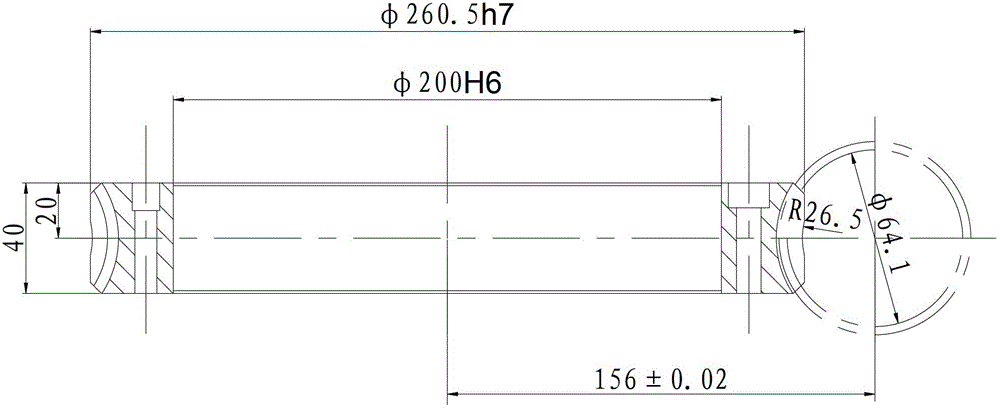

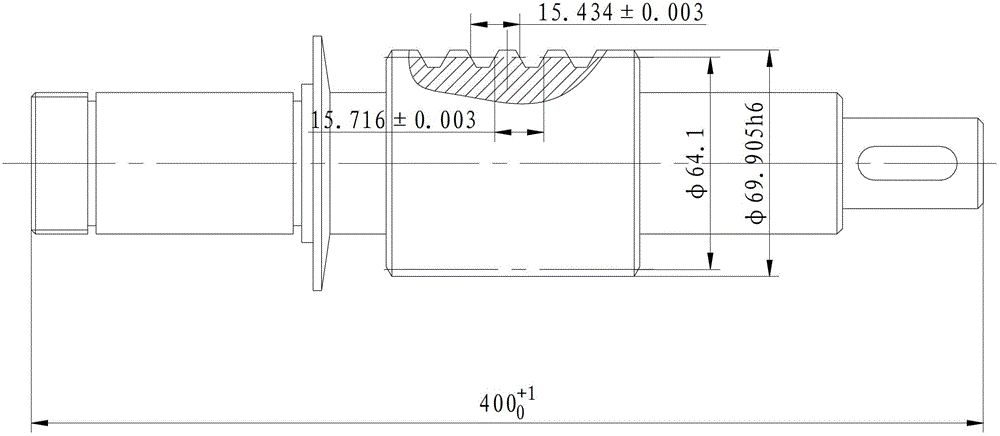

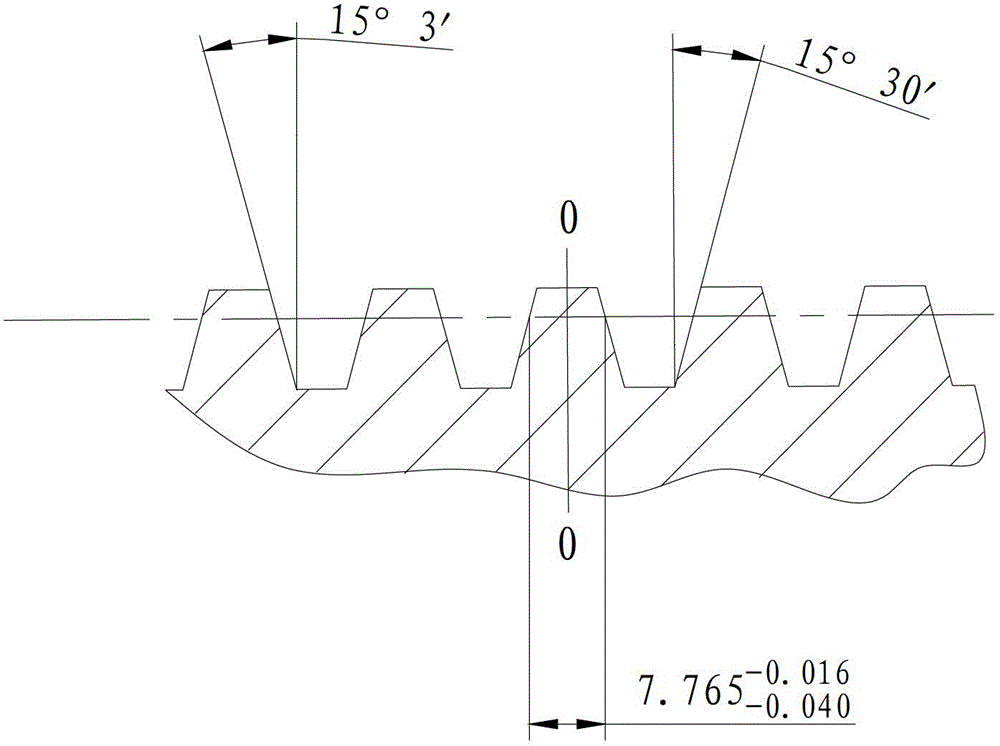

[0044] see Figure 1 to Figure 5 ,in figure 2 The arrow to the left indicates the thickening direction of the tooth thickness, the arrow to the right indicates the direction of thinning the tooth thickness, the vertical line at the root of the arrow to the left and the arrow to the right indicates the meshing center during assembly, Figure 5 The tooth shape in is the reference tooth shape for measurement.

[0045] figure 1 The parameters and technical requirements of the processed worm gear shown are: 1. Main parameters: center distance of worm gear pair: 156±0.02, axial modulus 4.958, number of teeth 50, nominal pitch circle helix angle 4°25′22″, helix direction Left, pressure angle 15°, meshing worm pitch circle diameter φ64.1, number of meshing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com