A face gear with layered structure and its realization method

A technology of layered structure and realization method, applied in belts/chains/gears, coatings, components with teeth, etc., can solve problems such as difficulty and increase in material cost, and achieve good wear resistance and high tooth surface hardness. , the effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

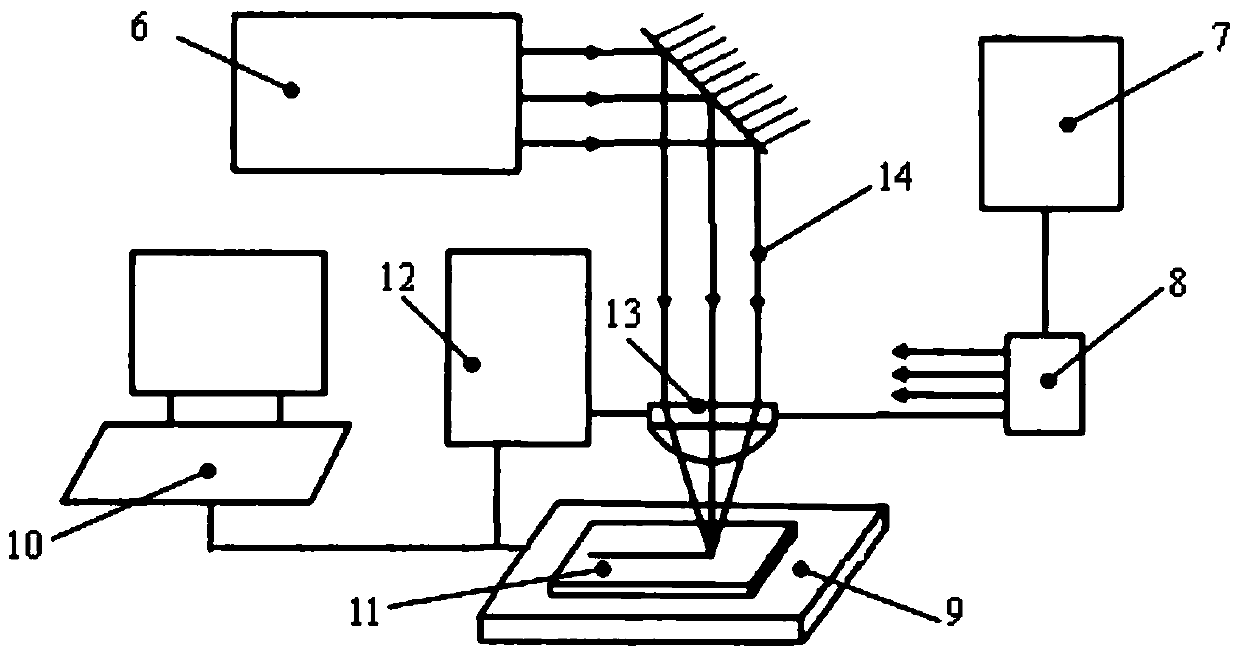

[0036] The embodiment of the present invention uses the laser cladding processing technology to realize the layered structure of the orthogonal offset face gear.

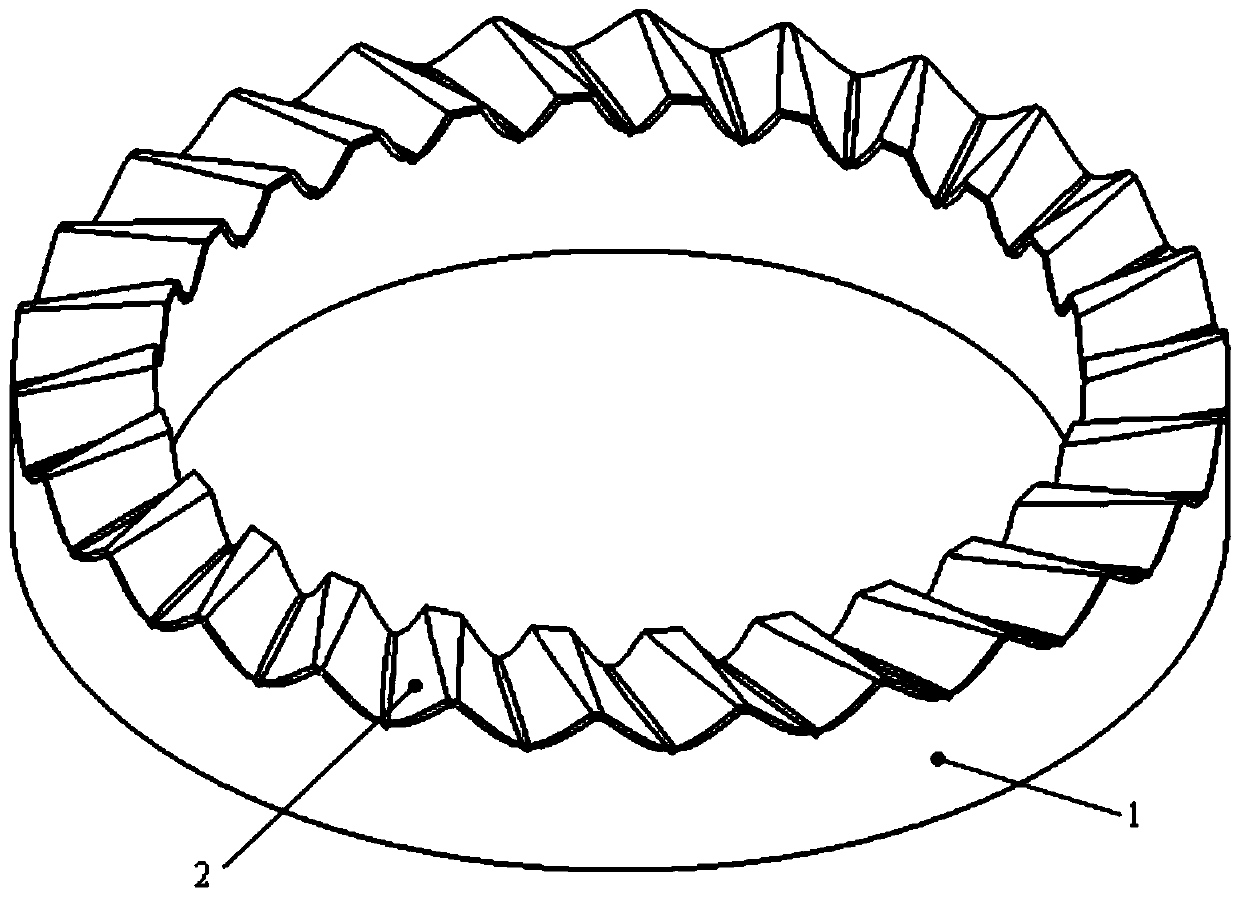

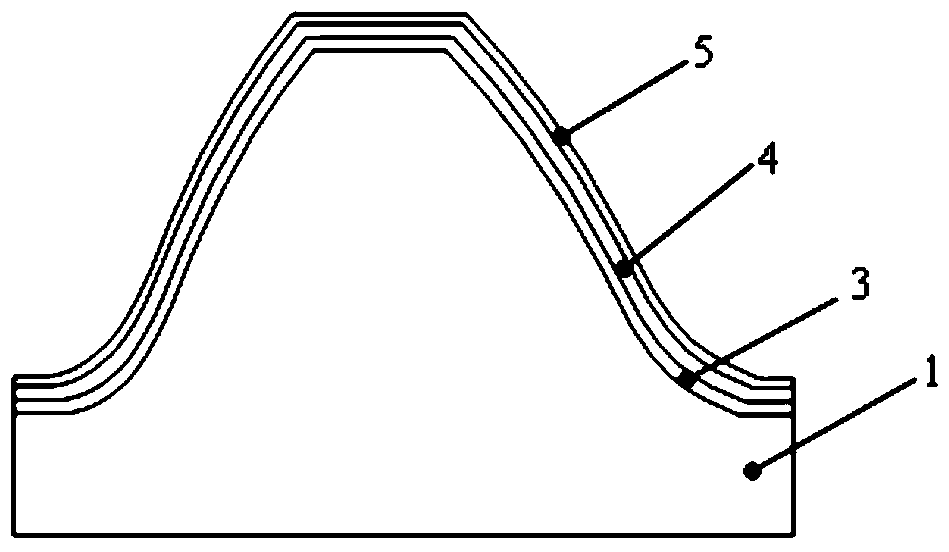

[0037] figure 1 It is a schematic diagram of the layered structure of the orthogonal offset face gear. The face gear tooth matrix 1 is processed on a special milling machine for face gears. According to the meshing size requirements of the face gear transmission and the thickness design of the cladding layer 2 on the tooth surface of the gear tooth, when the face gear tooth base 1 is milled, a certain thickness is reserved for the cladding layer 2 on the tooth surface of the gear tooth. The gear tooth surface cladding layer 2 can be a single-layer or multi-layer structure. When it is a single-layer structure, it should be ensured that the cladding layer material and the gear tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com