Improved tin-phosphor bronze alloy manufacturing process

A tin-phosphorus bronze and manufacturing process technology, applied in the field of improved tin-phosphorus bronze alloy manufacturing process, can solve the problems of short service life, high production cost and high economic cost, and achieve high temperature resistance, anti-glue ability, and anti-glue. Ability breakthrough, obvious effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

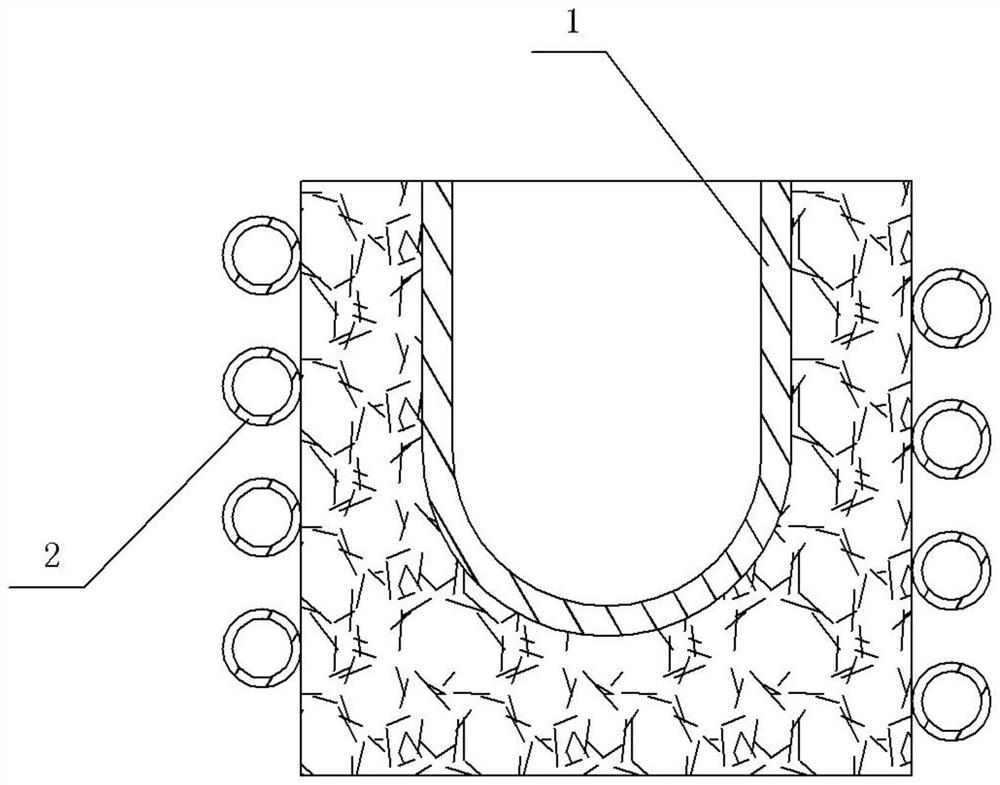

Image

Examples

Embodiment 1

[0025] The manufacturing process of tin phosphor bronze alloy comprises the following steps:

[0026] Step 1: Prepare an intermediate frequency melting furnace heated by electricity, that is, an electric heating furnace. The electric heating furnace includes a frequency conversion control cabinet modeled as KGPS, that is, a capacitor control cabinet. The control cabinet includes an MPU-2 type constant power thyristor intermediate frequency power supply control board; pour 100kg of red copper into an electric heating furnace and melt for 20 minutes.

[0027] Step 2: smelting 12 kg of refined tin by adding 12% of the mass of red copper into the electric heating furnace for 5 minutes, wherein the softness and purity of the refined tin are both 99.99%.

[0028] Step 3: Add 1% of the mass of copper into the electric heating furnace, that is, 1kg of red phosphorus, then add 100kg of red copper wire cut into the electric heating furnace, and continue smelting for 15 minutes, wherein ...

Embodiment 2

[0032] The difference from Example 1 is: in the step 2, more than 9% of the mass of red copper is added to the electric heating furnace, that is, 9.1kg (9.1%) of refined tin; in the step 3, more than 0.6% of the mass of red copper is added to the electric heating furnace , that is, 0.61kg (0.61%) of red phosphorus.

Embodiment 3

[0034] The difference from Example 1 is: in the step 2, 14% of the quality of red copper is mixed into the electric heating furnace, that is, 14kg of refined tin; in the step 3, 1.2% of the quality of red copper is mixed into the electric heating furnace, that is, red phosphorus .

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com