A round-toothed knife for a plastic pulverizer and its grinding tool

A pulverizer and scalloped technology, which is applied in the direction of grinding workpiece supports, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem that the scalloped scalloped cutter is not easy to fix, achieve small particle size, reduce damage rate, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

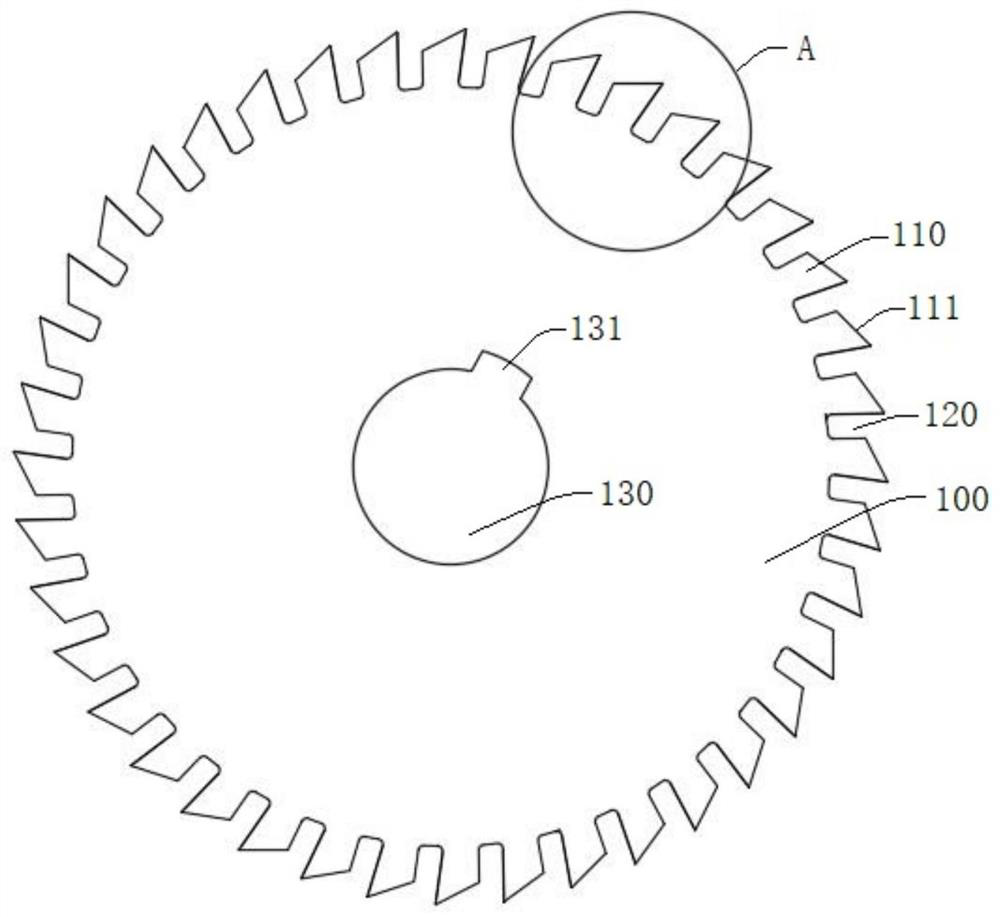

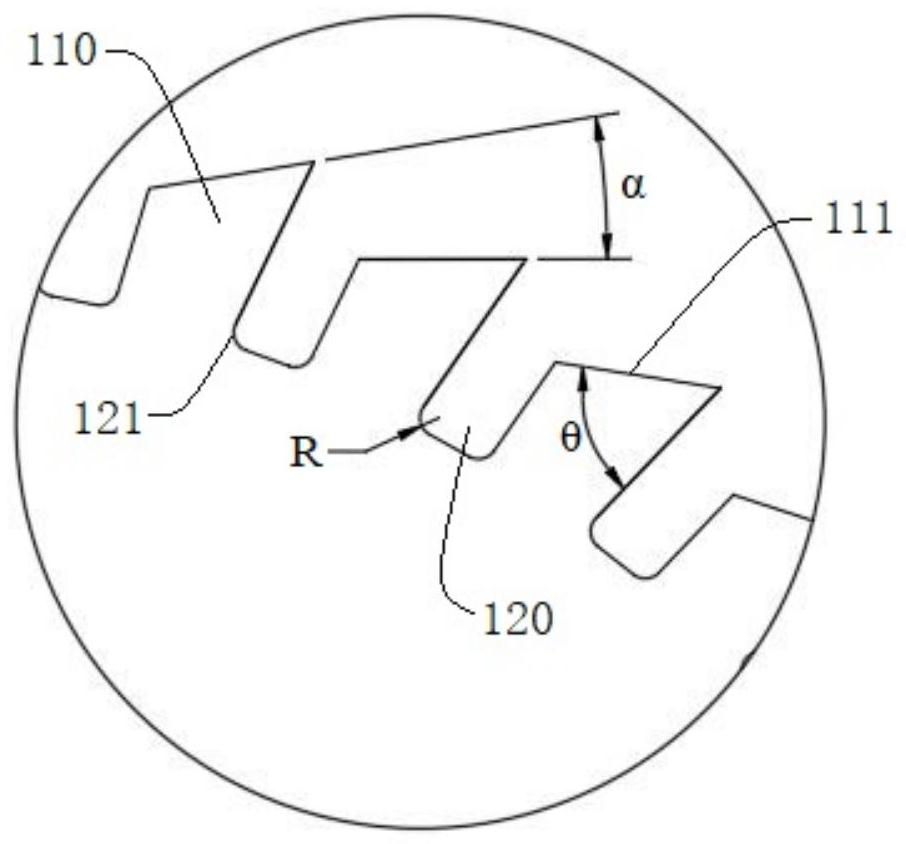

[0058] Such as figure 1 As shown, a circular tooth cutter for a plastic pulverizer includes a cylindrical cutter body 100, cutter teeth 110, tooth grooves 120 and mounting holes 130 are provided on the cutter body 100, and 40 cutter teeth 110 are evenly distributed In the peripheral length direction of the cutter body 100, the cutter tooth 110 is provided with a cutting edge surface 111, combined with figure 2 As shown, the blade angle formed by the cutting edge surface 111 is θ, θ=55°, and the angle α formed between the cutting edge surfaces 111 on two adjacent cutter teeth 110 is 9°; The space formed between two cutter teeth 110 is an arc angle square groove, that is, an arc surface 121 is provided on the edge of the slot bottom length direction of the tooth groove 120, wherein the radius of the arc surface 121 is 1 mm, preventing the teeth from The groove bottom of the groove 120 forms a sharp corner, and the sharp corner is in the process of crushing. When the material c...

Embodiment 2

[0073] A round-toothed cutter for a plastic pulverizer in this embodiment and its grinding tooling and processing technology are basically the same as in Embodiment 1, the difference being that there are 30 cutter teeth 110, that is, two adjacent cutter teeth 110 The angle α formed between the cutting edge surfaces 111 is 12°; the edge angle formed by the cutting edge surfaces 111 is θ, θ=50°; the radius of the arc surface 121 is 1.3 mm.

[0074] According to the above description of the grinding tooling structure of the circular tooth cutter for plastic pulverizers, the following is the method of using the grinding tooling, and the steps are as follows:

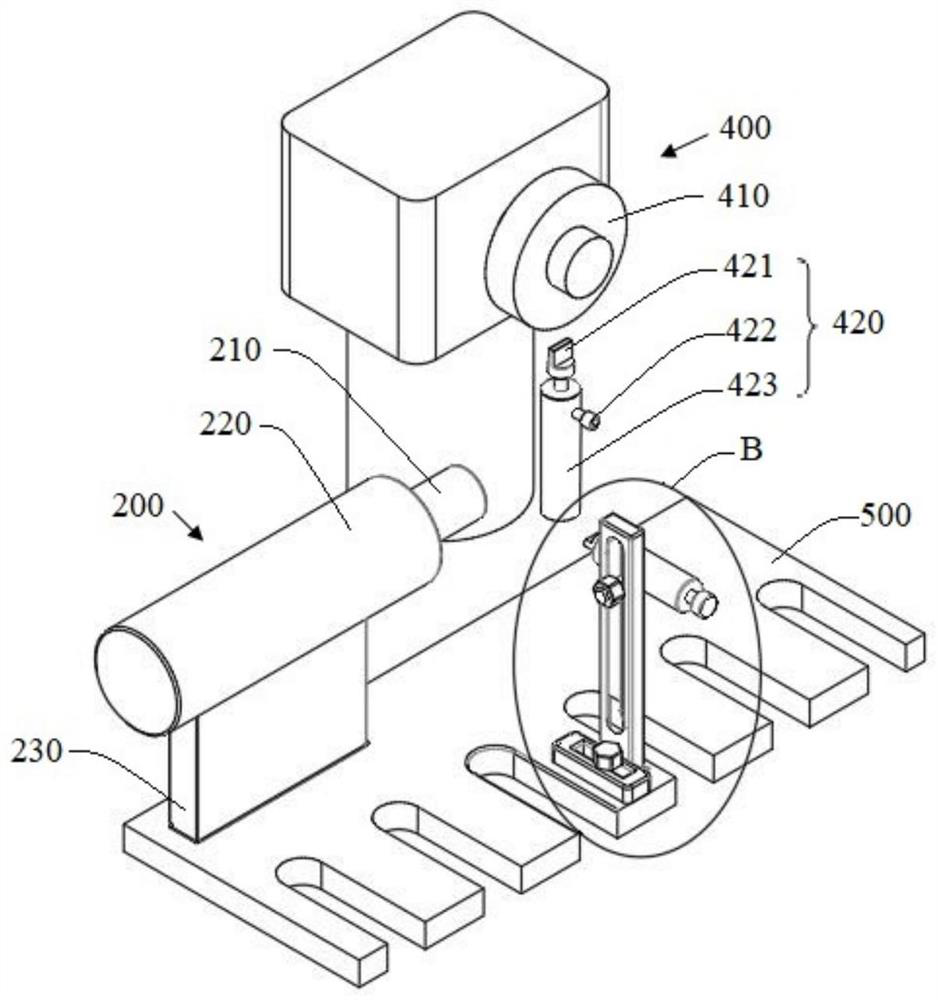

[0075] (1) The installation unit 200 is fixed on the mold base 500 through its support 230 , the positioning unit 300 is fixed on the mold base 500 through its fixing base 340 , and is located on one side of the installation part 210 on the installation unit 200 ;

[0076] (2) Fit the installation hole 130 of the tool body 1...

Embodiment 3

[0082] In this embodiment, a circular tooth cutter for a plastic pulverizer and its grinding tooling and processing technology are basically the same as in Embodiment 1, the difference being that there are 50 cutter teeth 110, that is, two adjacent cutter teeth 110 The angle α formed between the cutting edge surfaces 111 is 7.2°; the edge angle formed by the cutting edge surfaces 111 is θ, θ=60°; the radius of the arc surface 121 is 0.7 mm.

[0083] According to the above description of the grinding tooling structure of the circular tooth cutter for plastic pulverizers, the following is the method of using the grinding tooling, and the steps are as follows:

[0084] (1) The installation unit 200 is fixed on the mold base 500 through its support 230 , the positioning unit 300 is fixed on the mold base 500 through its fixing base 340 , and is located on one side of the installation part 210 on the installation unit 200 ;

[0085] (2) Fit the installation hole 130 of the tool bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com