Flexible circuit board gum inhibition release paper release layer hot-melt resin composition, gum inhibition release paper and production method of gum inhibition release paper

A resin composition, flexible circuit board technology, applied in coating, paper, papermaking and other directions, can solve the problems of difficult control, poor release and glue resistance, secondary pollution of circuit boards, etc., to improve the melting point and increase resistance. Glue function, the effect of easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

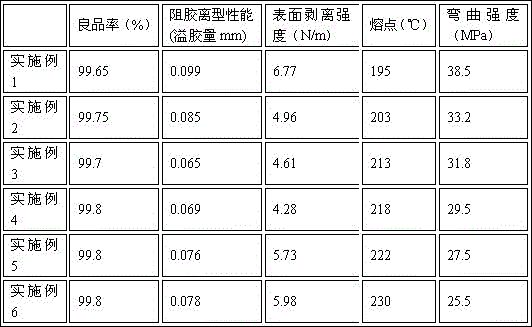

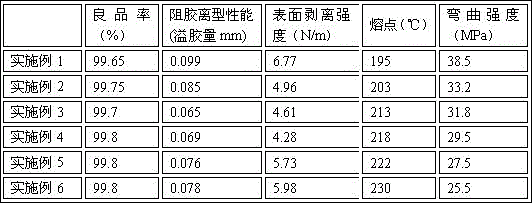

Embodiment 1

[0060] The modified resin coating formula is 30 parts by mass of polypropylene (PP) material, 60 parts of poly-4-methylpentene (TPX), 5 parts of polyethylene (PE) material, and 5 parts of polybutylene terephthalate Diester (PBT), 0.1 part by mass of 2,2′-methylene-bis-(4,6-di-tert-butylphenoxy)sodium phosphate, 0.2 part of tetrakis[β-(3,5-di-tert Butyl-4-hydroxyl base) propionate] pentaerythritol ester, 0.1 part of zinc glycerate, the resin mixing sequence is: first add polypropylene, poly-4-methylpentene, polyethylene, zinc glycerate and stir with a high-speed mixer After 4 minutes, add 2,2′-methylene-bis-(4,6-di-tert-butylphenoxy)sodium phosphate, tetrakis[β-(3,5-di-tert-butyl-4-hydroxy basic) propionate] pentaerythritol ester. Blend on high speed for 5 minutes. Stir evenly and enter the hot melt extruder to extrude and coat on the fiber base paper in a molten state at 280°C, with a coating weight of 20g / m 2 . Surface micropores are formed by high-frequency corona, the s...

Embodiment 2

[0062] The modified resin coating formula is 25 parts by mass of polypropylene (PP) material, 60 parts of poly-4-methylpentene (TPX), 3 parts of polyethylene (PE) material, 12 parts of polybutylene terephthalate Diester (PBT), 0.2 parts by mass of 2,2′-methylene-bis-(4,6-di-tert-butylphenoxy) sodium phosphate, 0.3 tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxy base) propionate] pentaerythritol ester, 0.2 parts of zinc glycerate, and the resin mixing sequence is as in Example 1. After stirring evenly, enter the hot melt extruder to extrude and coat on the fiber base paper in a molten state at 300°C, and the coating amount is 30g / m 2 . Surface micropores are formed by high-frequency corona, the surface peeling strength is 4.96N / m, the melting point temperature is 203°C, the bending strength is 33.2MPa, and the resistance to glue (overflow) is 0.075-0.094mm.

Embodiment 3

[0064] The modified resin coating formula is 15 parts by mass of polypropylene (PP) material, 68 parts of poly-4-methylpentene (TPX), 2 parts of polyethylene (PE) material, 15 parts of polybutylene terephthalate Diester, 0.3 parts by mass of 2,2′-methylene-bis-(4,6-di-tert-butylphenoxy)sodium phosphate, 0.3 parts of tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxy-based) propionate] pentaerythritol ester, 0.3 parts of zinc glycerate, the resin mixing sequence according to Example 1, stir evenly, enter the hot-melt extruder, extrude and coat on the fiber-based paper in a molten state at 300 ° C, coat The cloth weight is 40g / m 2 . Surface micropores are formed by high-frequency corona, the surface peeling strength is 4.61N / m, the melting point temperature is 213°C, the bending strength is 31.8MPa, and the resistance to glue (adhesive overflow) is 0.056-0.073mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com