Full automatic cigarette conveying device

A conveying device and fully automatic technology, applied in the field of tobacco, can solve problems such as easy fatigue and affecting judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

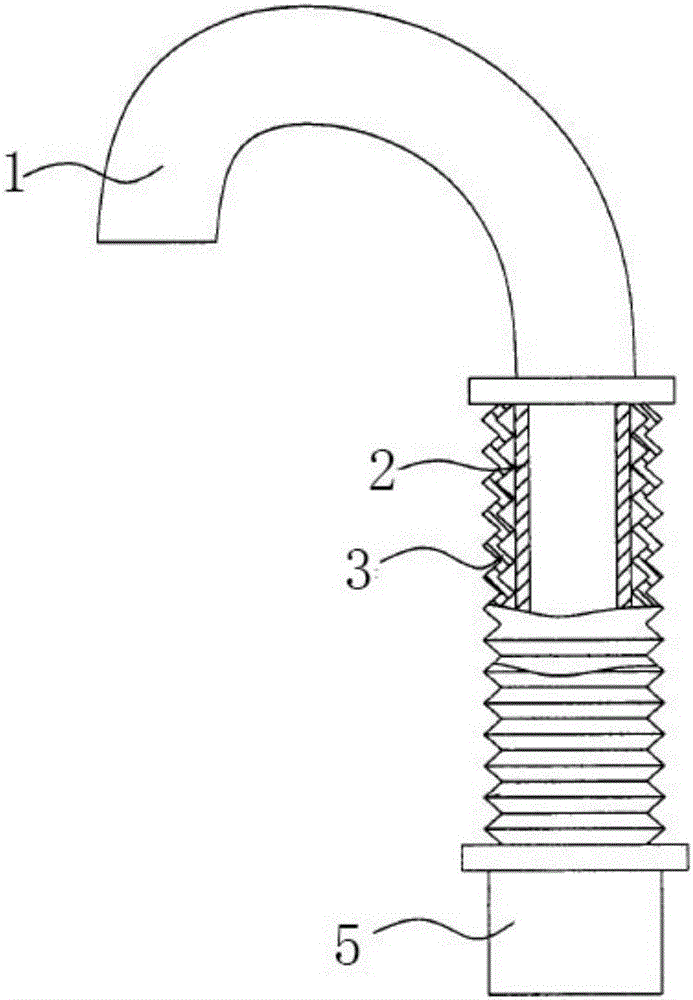

[0038] The device of the present invention comprises an inspection device body 1, a general inspection device base 5 and a plurality of detachable sub-inspection device bases, such as figure 1 As shown, the inspection device body 1 is detachably arranged on the base 5 of the general inspection device, while the sub-inspection device bases are installed in different positions, which is convenient for users to use. The base 5 of the general inspection device is connected with a cigarette conveying roller. The base 5 of the general inspection device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-inspection devices are respectively provided with laser emitting components 6 .

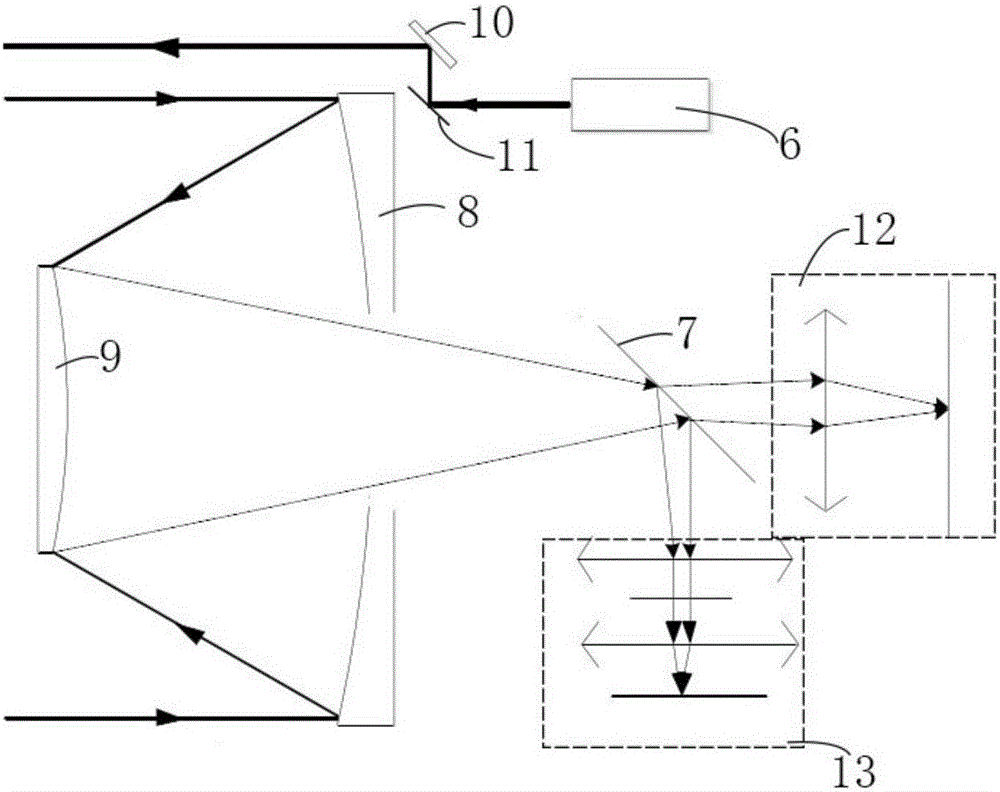

[0039] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alo...

Embodiment 2

[0075] The device of the present invention comprises an inspection device body 1, a general inspection device base 5 and a plurality of detachable sub-inspection device bases, such as figure 1 As shown, the inspection device body 1 is detachably arranged on the base 5 of the general inspection device, while the sub-inspection device bases are installed in different positions, which is convenient for users to use. The base 5 of the general inspection device is connected with a cigarette conveying roller. The base 5 of the general inspection device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-inspection devices are respectively provided with laser emitting components 6 .

[0076] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alo...

Embodiment 3

[0112] The device of the present invention comprises an inspection device body 1, a general inspection device base 5 and a plurality of detachable sub-inspection device bases, such as figure 1 As shown, the inspection device body 1 is detachably arranged on the base 5 of the general inspection device, while the sub-inspection device bases are installed in different positions, which is convenient for users to use. The base 5 of the general inspection device is connected with a cigarette conveying roller. The base 5 of the general inspection device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-inspection devices are respectively provided with laser emitting components 6 .

[0113] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com