A gear modification method for reducing the contact temperature of gear tooth surfaces

A technology of surface contact and gear teeth, which is applied to components with teeth, gear lubrication/cooling, belts/chains/gears, etc., to achieve temperature reduction, improve anti-gluing performance, and reduce the maximum tooth surface contact temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

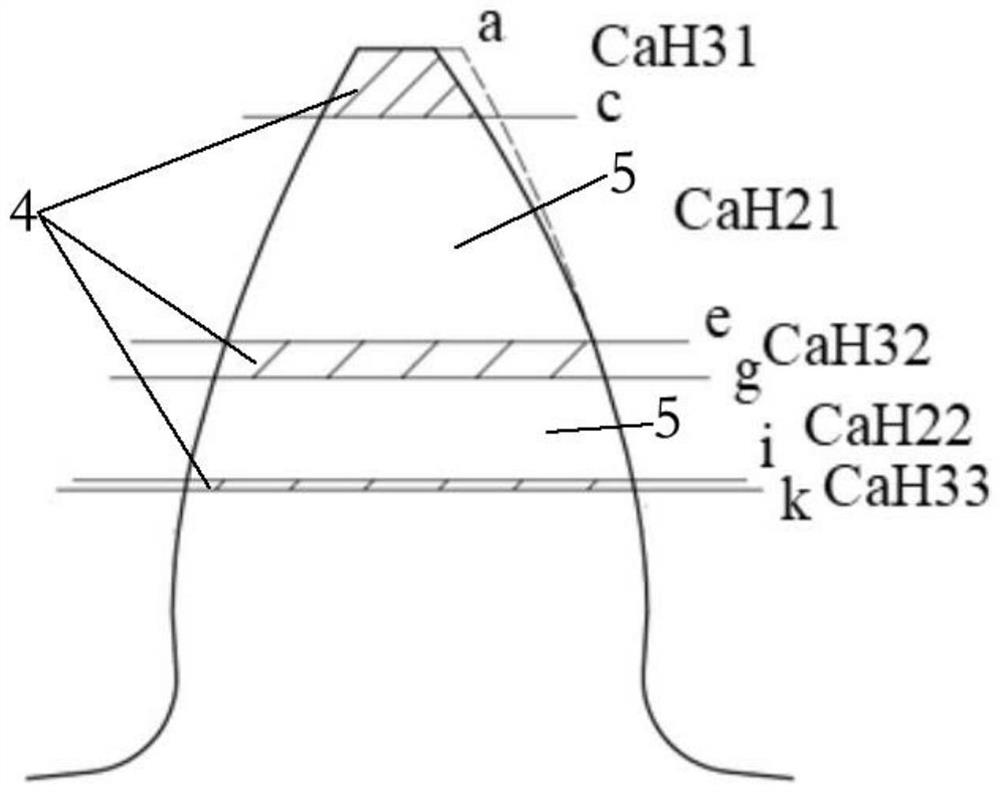

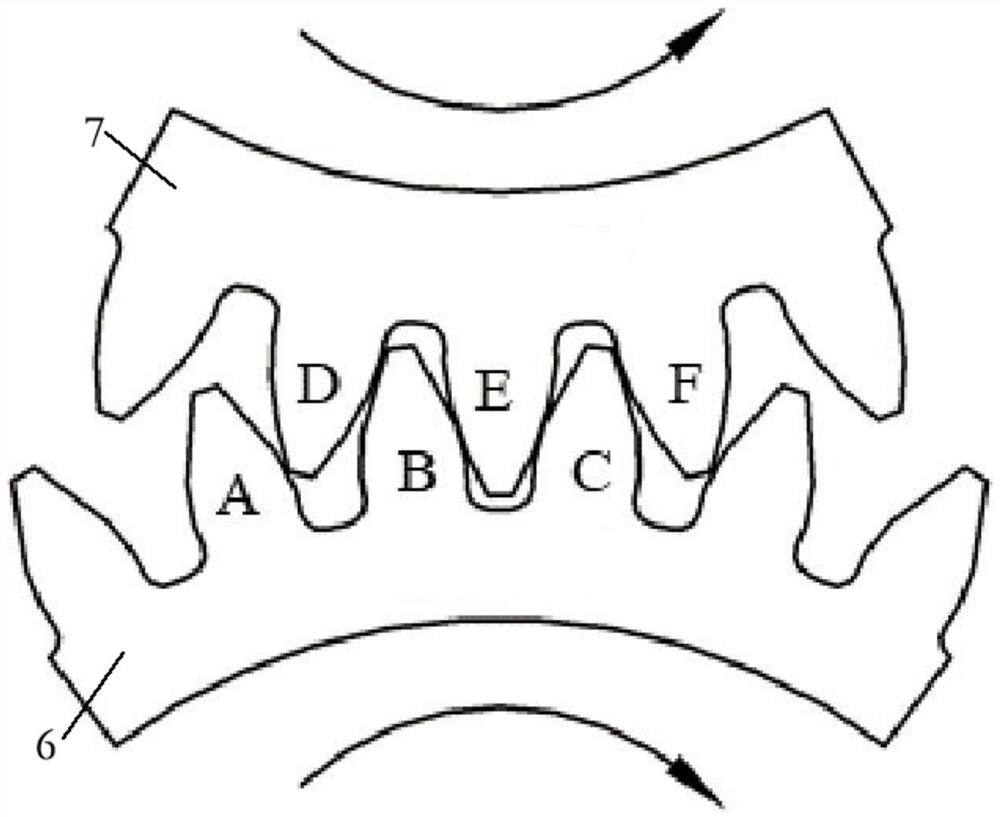

[0029] Figure 1-Figure 7 Embodiment 1 of the present invention is shown.

[0030] A gear modification method for reducing the contact temperature of gear tooth surfaces, comprising the following steps:

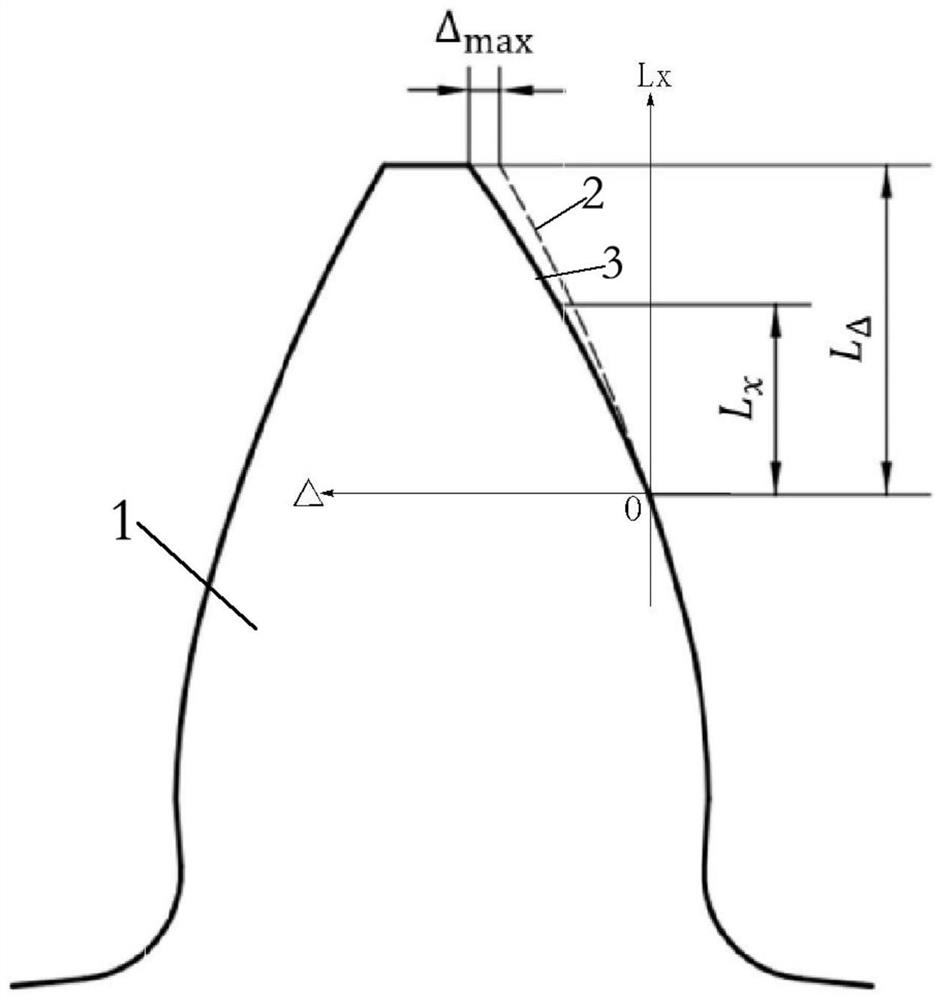

[0031] S1: Select the tooth profile corresponding to the three-tooth meshing area 4 and the two-tooth meshing area 5 closest to the tooth tip on the gear tooth 1 as the tooth profile 2 to be modified;

[0032] S2: Establish a plane rectangular coordinate system (O-L X Δ), the plane Cartesian coordinate system (O-L X Δ) of the ordinate axis L X Parallel to the radial direction of the gear, the abscissa axis of the plane rectangular coordinate system is the modification amount Δ;

[0033] S3: Calculate the maximum modification amount Δ of the end point relatively close to the tooth tip on the tooth profile 2 to be modified max ;

[0034] Δ max Determined according to the force deformation of gear tooth 1 and the base pitch deviation and tooth profile tolerance of gear to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com