Process for preparing lubricating oil containing cholesterol

A technology for lubricating oil and cholesterol is applied in the field of preparation of lubricating oil containing cholesterol, which can solve the problems of low anti-adhesion ability of mechanical oil and achieve the effect of improving the anti-adhesion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention adds 0.05% to 4.0% cholesterol in lubricating oil as an additive, heats to 80°C to 90°C, stirs evenly, and then cools to normal temperature for use. Described lubricating oil is machine oil.

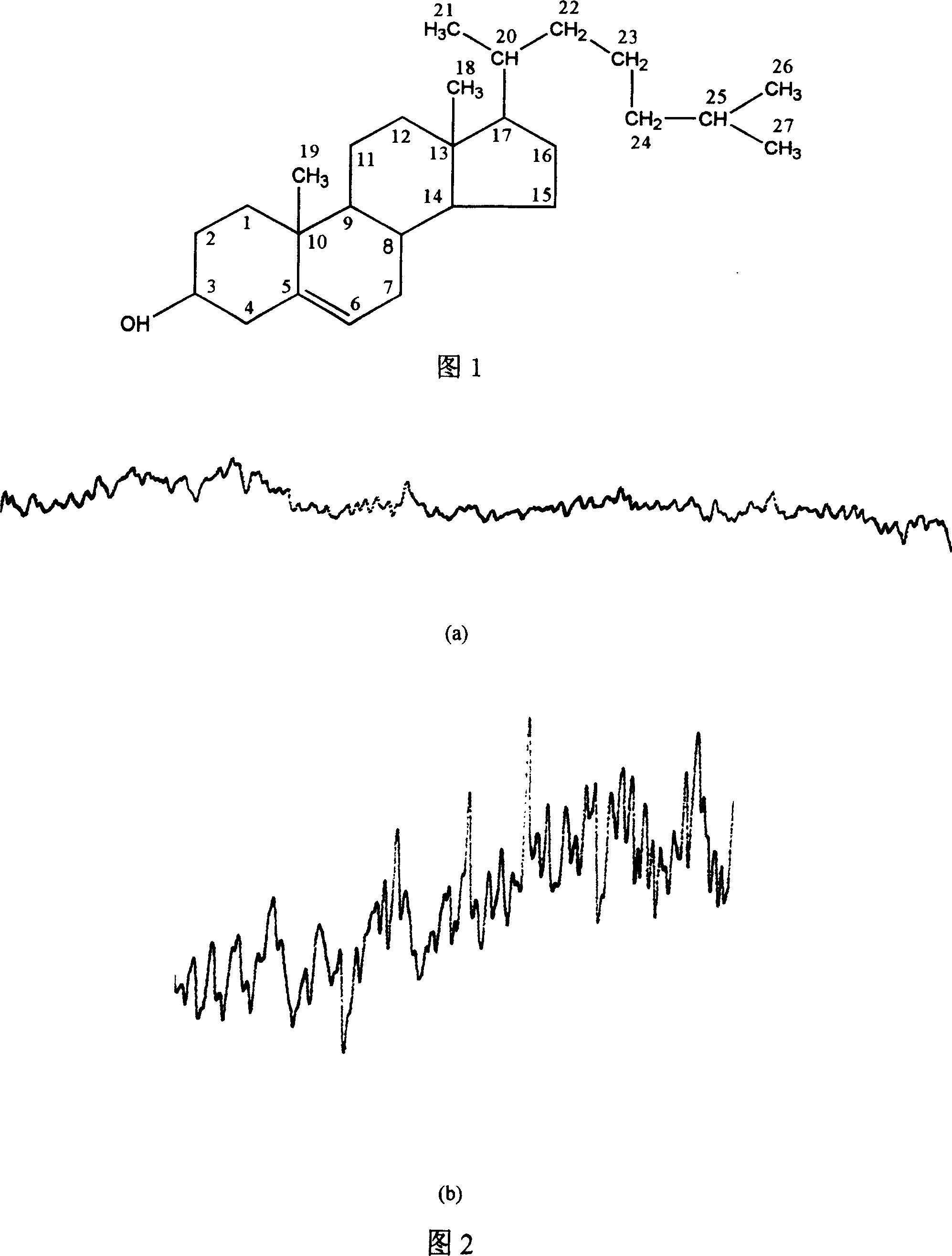

[0013] The molecular formula of cholesterol is shown in Figure 1. The structure of cholesterol is characterized by a β-configured hydroxyl group on C-3, a double bond between C-5 and C-6, and a A hydrocarbyl side chain of 8 carbon atoms.

[0014] Adding 0.05%-4.0% (weight) of cholesterol to the lubricating oil, then heating the lubricating oil and stirring the lubricating oil, the cholesterol is evenly dispersed in the lubricating oil. After the lubricating oil cools down, it can be used.

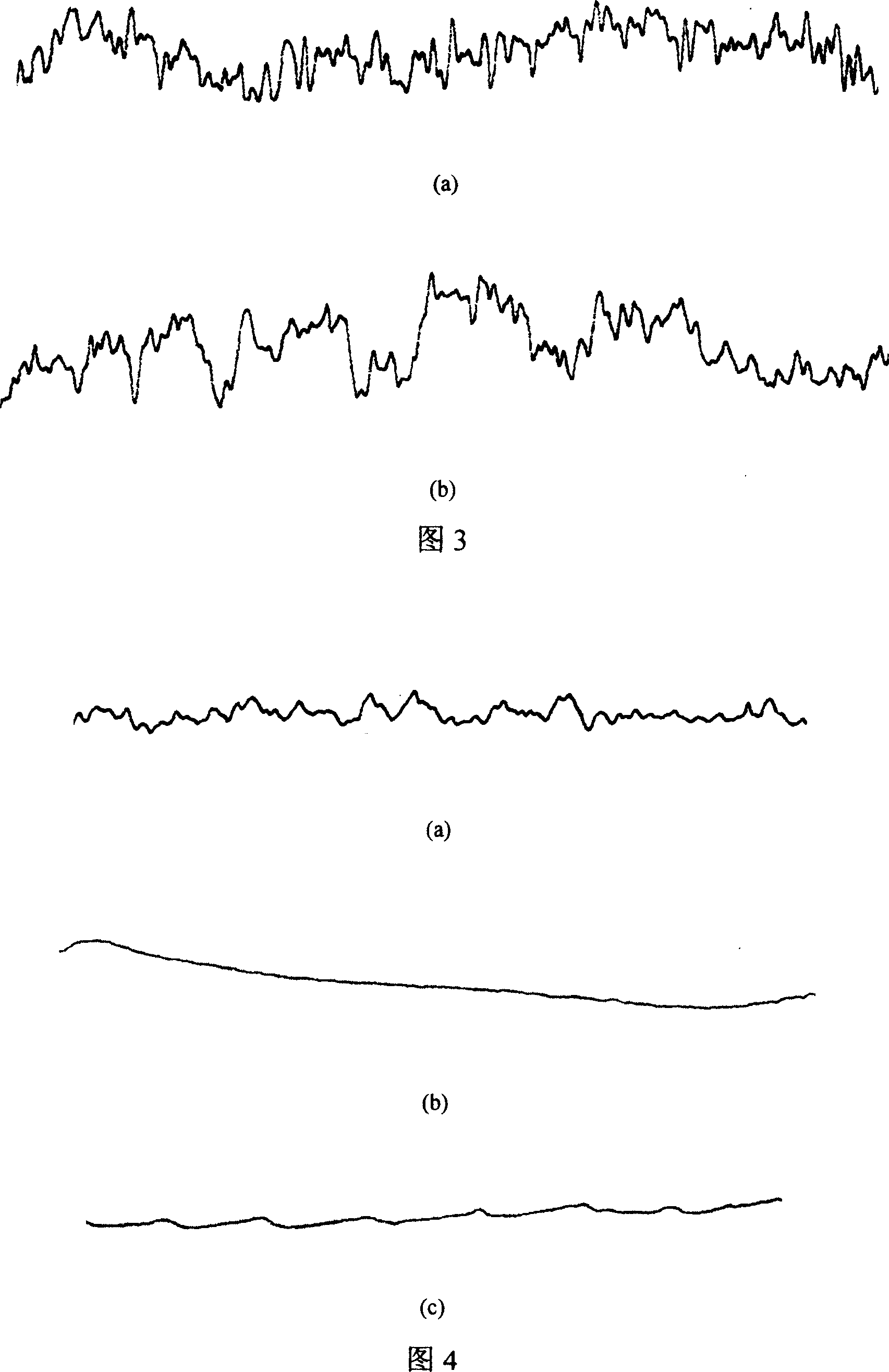

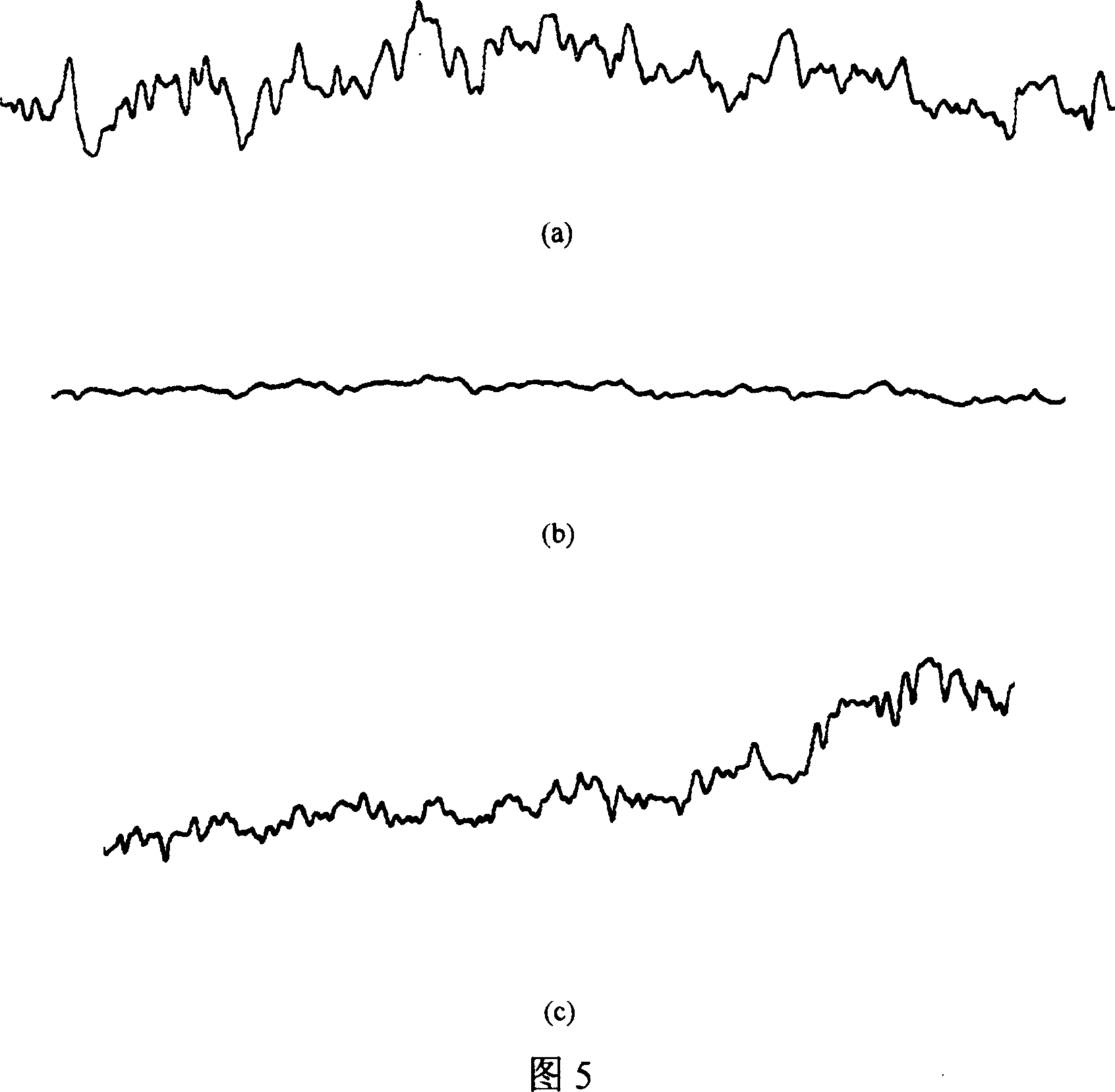

[0015] Fig. 2, Fig. 3, Fig. 4, Fig. 5 are typical case experiment results of the present invention, evaluate the tribological mechanical property of lubricating oil with the four-ball test of MMW-1 type vertical universal friction and wear testing machine.

[0016] Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com