Medium-and-high-temperature solar selective absorption coating and preparation method thereof

A technology for absorbing coating and solar energy, applied in the field of solar energy utilization, can solve the problems of the overall performance change of the coating, the damage of the coating structure, and the complex process, and achieve the effects of good high temperature stability, high absorption rate, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

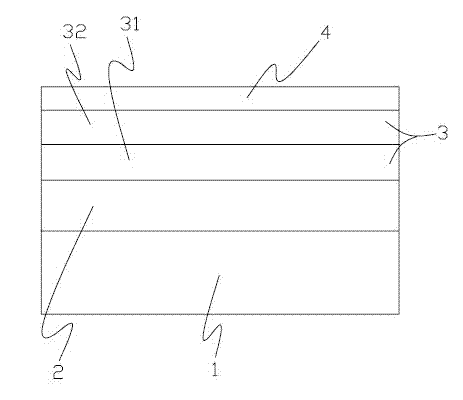

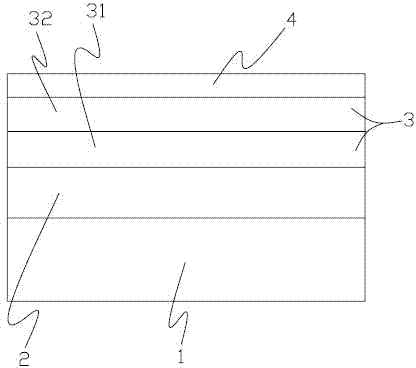

[0027] As shown in the drawings of the description, the selective absorption coating of the present invention includes three layers of film, from the substrate 1 to the surface are infrared reflection layer 2, absorption layer 3 and anti-reflection layer 4 in sequence. The bottom infrared reflective layer 2 is made of Mo film with a thickness of 50-200nm; the absorption layer 3 includes a first sublayer 31 and a second sublayer 32, and the first sublayer 31 and the second sublayer 32 are made of Composed of Mo+AlN films with a thickness of 30-150 nm; the anti-reflection lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com