Low-emissivity film-coated glass high in infrared reflection and sandwich glass product thereof

A technology of low-radiation coating and infrared reflection layer, which is applied in the field of glass coating, can solve problems such as inappropriate diffusion of oxygen atoms, and achieve the effects of improved mechanical durability, qualified optical quality, and improved chemical durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

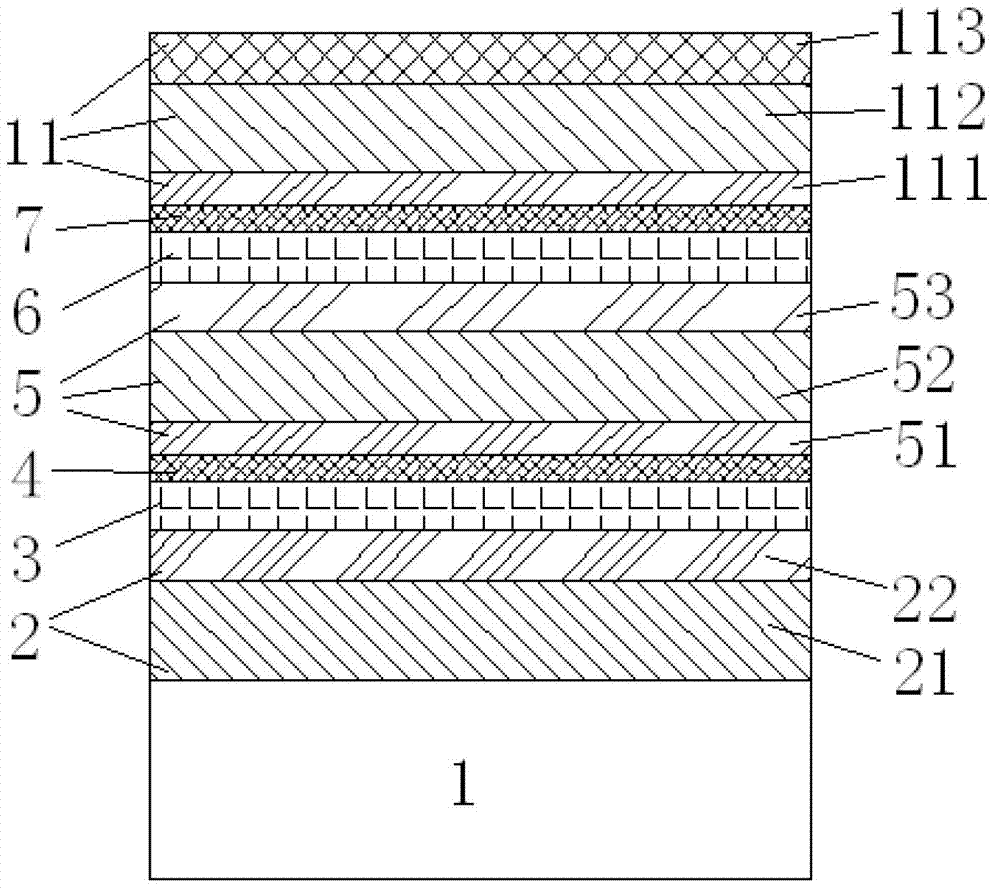

[0045] Sodium calcium silicate float green glass with a thickness of 2.1 mm is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for deposition. The background vacuum is higher than 9× 10 -4 Pa. According to the different film structures shown in Table 2, they were sequentially deposited on the glass. where ZrO 2 Using Zr metal target in Ar / O 2 Intermediate Frequency Reactive Sputtering Deposition in a Mixed Atmosphere with a Flow Ratio of 3 / 1, TiO 2 Using TiOx ceramic target in Ar and containing trace O 2 (O 2 Medium frequency sputtering deposition in an atmosphere with a flow ratio of 5%. The film materials and thicknesses of the other layers are shown in Table 2, and the sputtering process is also well known to those skilled in the art, so they will not be described in detail here.

[0046] Table 2: Comparative Examples 1-3 and Examples 1-6 Film Structure and Comparison of Appearance and Key Technical In...

Embodiment 7~10

[0056] Sodium calcium silicate float green glass with a thickness of 2.1 mm is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for deposition. The background vacuum is higher than 9× 10 -4 Pa. According to the different film structures shown in Table 4, they were sequentially deposited on the glass. where ZrO 2 Using Zr metal target in Ar / O 2 Intermediate frequency reactive sputtering deposition under mixed atmosphere with flow ratio of 3 / 1. The film materials and thicknesses of the other layers are shown in Table 4, and the sputtering process is also well known to those skilled in the art, so they will not be detailed here.

[0057] Table 4: Comparison of the film structure of Examples 7-10 and the appearance and key technical indicators before and after high-temperature heat treatment

[0058]

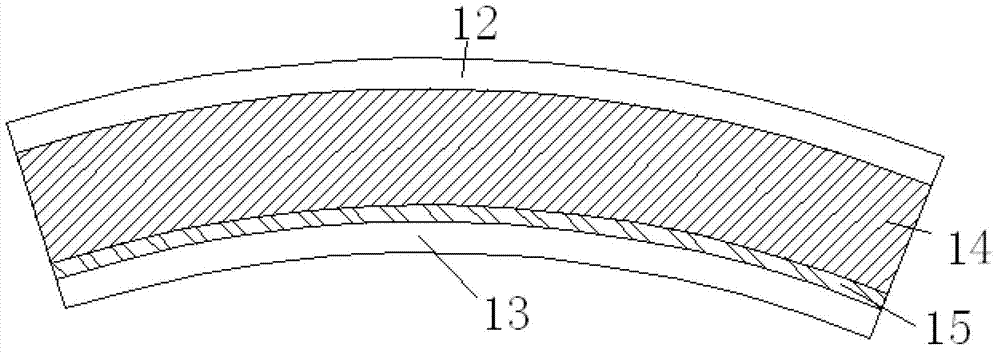

[0059] After the vacuum coating is completed, according to the auto glass baking and bending process, carry ...

Embodiment 11~12

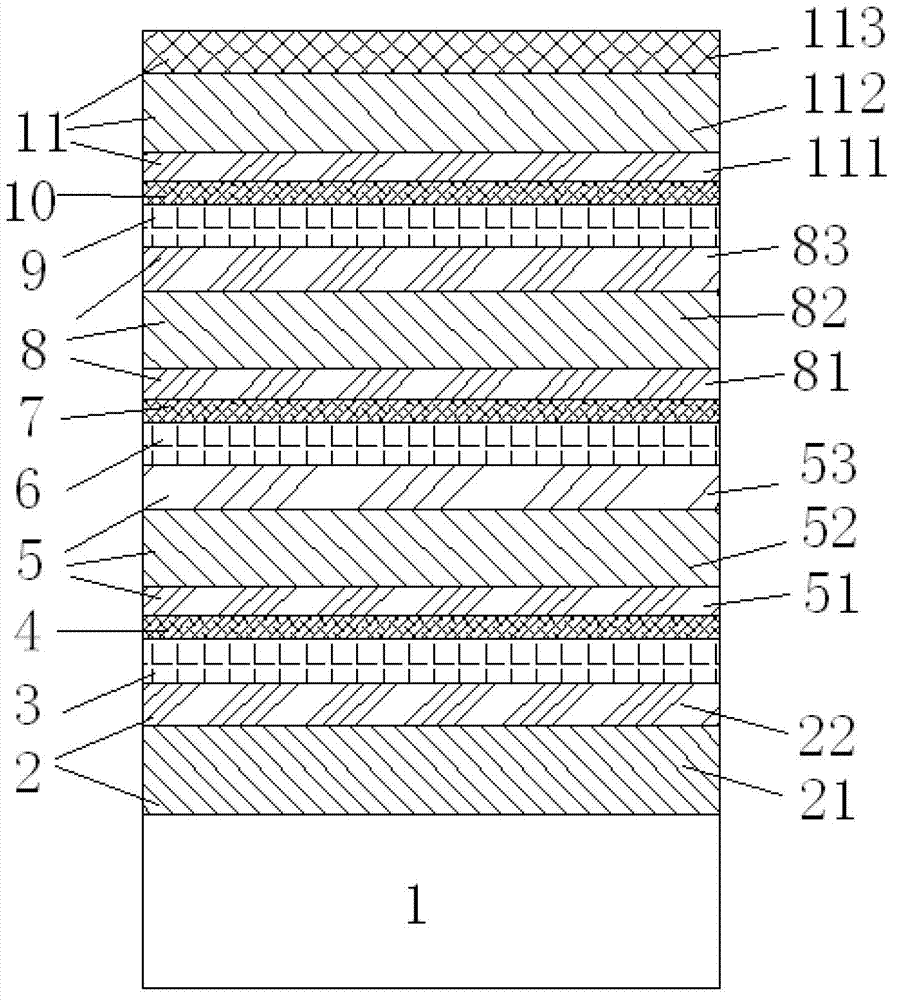

[0061] Sodium calcium silicate float white glass with a thickness of 2.1 mm is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for deposition. The background vacuum is higher than 9× 10 -4 Pa. Low-emissivity films containing three infrared reflective layers were sequentially deposited on glass as shown in Table 5. where ZrO 2 Using Zr metal target in Ar / O 2 Medium frequency reactive sputtering deposition under the mixed atmosphere with flow ratio of 3 / 1, and ZrOxNy using Zr metal target in Ar / O 2 / N 2 Intermediate frequency reactive sputtering deposition in a mixed atmosphere with a flow ratio of 6 / 2 / 1. The film materials and thicknesses of the other layers are shown in Table 5, and the sputtering process is also well known to those skilled in the art, so they will not be detailed here.

[0062] Table 5: Comparative Example 4 and Examples 11-12 film structure and appearance and key technical indicators com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com