Copper nanowire / copper film composite structure and preparation method thereof

A copper nanowire and composite structure technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of high substrate requirements, large deposition angle, high cost, etc., and achieve high deposition efficiency, The effect of fast sputtering rate and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take an ordinary glass piece and place it in absolute ethanol for ultrasonic cleaning for 8 minutes, then rinse it repeatedly with deionized water for more than 3 times, and then dry the glass piece in an oven at 80°C;

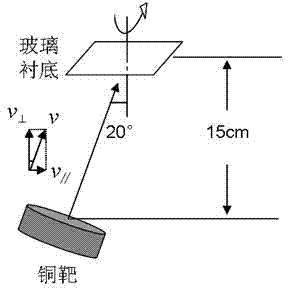

[0026] 2) Fix the prepared glass substrate on the sample tray, install a copper target with a purity of 99.99%, and adjust the copper target to the substrate at 20 ° , adjust the distance between the substrate and the copper target to be 15cm;

[0027] 3) Close the chamber door and vacuum the chamber to 5×10 -4 Pa, the substrate is not heated (about 20°C);

[0028] 4) High-purity Ar gas with a flow rate of 20sccm and a purity of 99.999%, keep the chamber pressure at 0.2Pa, turn on the DC sputtering source, adjust the sputtering power to DC 120W and pre-sputter for 5 minutes to remove possible oxidation on the surface of the copper target Floor;

[0029] 5) No bias was applied to the substrate, the rotation speed of the sample disc was adjusted to...

Embodiment 2

[0032] 1) Same as embodiment 1;

[0033] 2) Same as embodiment 1;

[0034] 3) Raise the substrate temperature to 200°C, and the rest are the same as in Example 1;

[0035] 4) Same as embodiment 1;

[0036] 5) Same as embodiment 1.

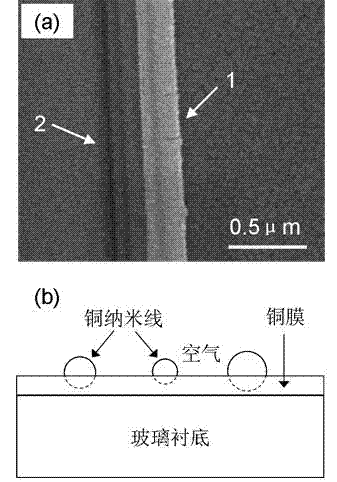

[0037] In the copper nanowire / copper film composite structure prepared in this example, the thickness of the copper film is 57 nm, the length of the copper nanowire is 0.5-4 mm, and the diameter is 100-400 nm. The density of the copper nanowire on the copper film is about 6.7×10 2 / mm 2 .

Embodiment 3

[0039] 1) Same as embodiment 1;

[0040] 2) Same as embodiment 1;

[0041] 3) Same as embodiment 1;

[0042] 4) Same as embodiment 1;

[0043] 5) The thickness of the copper film is 81nm, and the rest are the same as in Embodiment 1.

[0044] In the copper nanowire / copper film composite structure prepared in this example, the thickness of the copper film is 81 nm, the length of the copper nanowire is 0.1-3 mm, and the diameter is 100-450 nm. The density of the copper nanowire on the copper film is about 3.3×10 2 / mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com