Method for preparing tantalum oxide film by direct current magnetron sputtering method

A technology of DC magnetron sputtering and tantalum oxide, which is applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of insufficient response speed, low cycle life of devices, and research on fast ion thin films. few questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

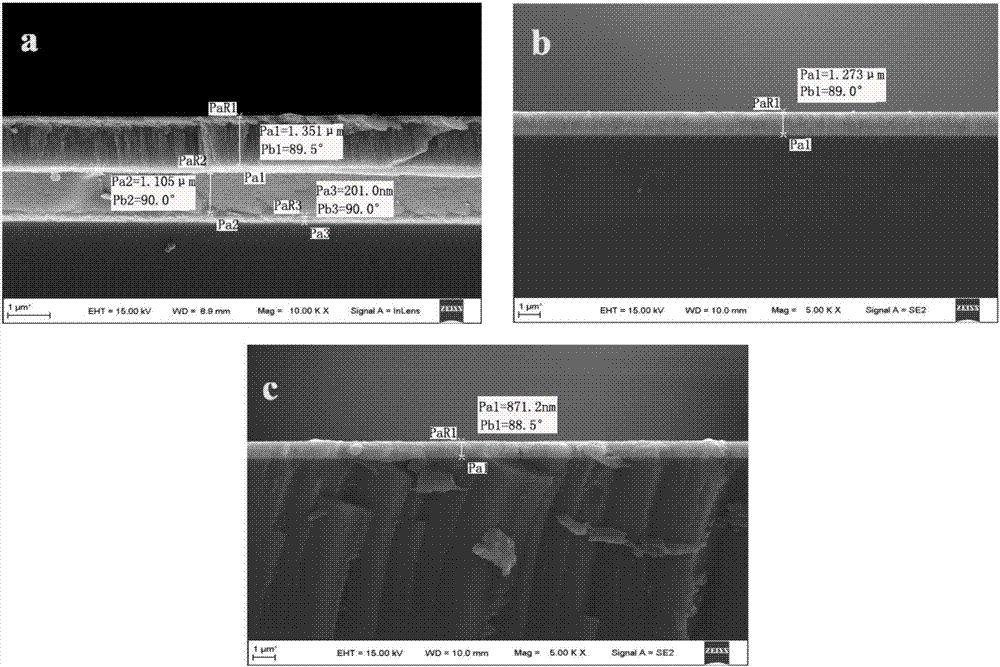

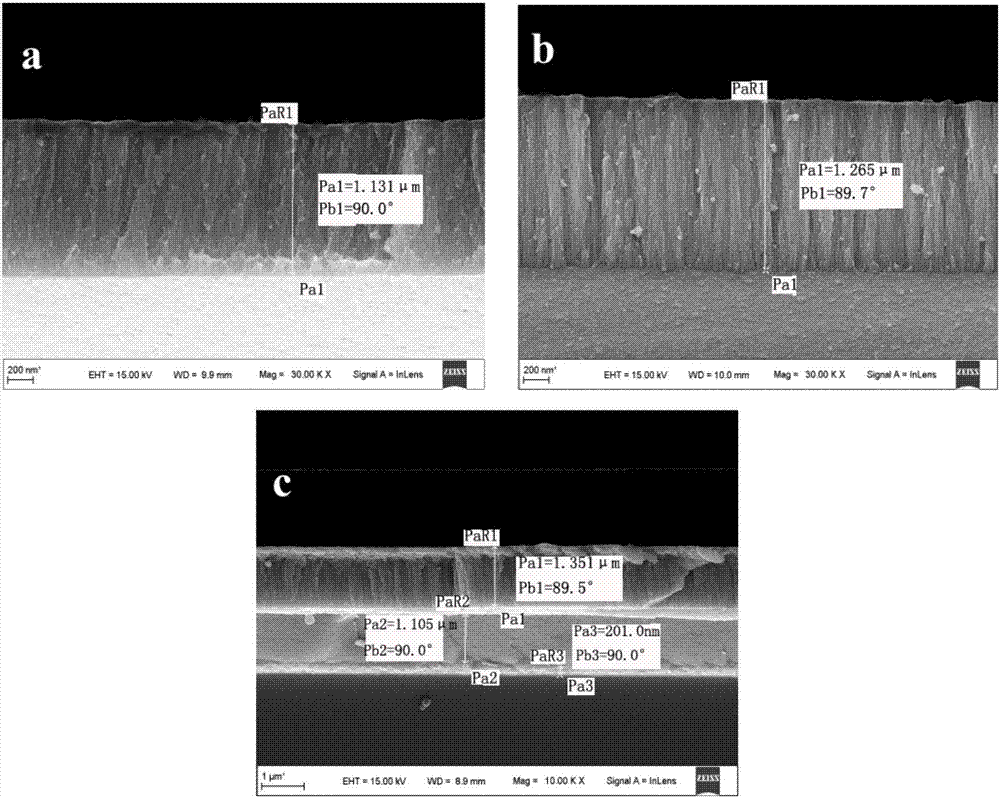

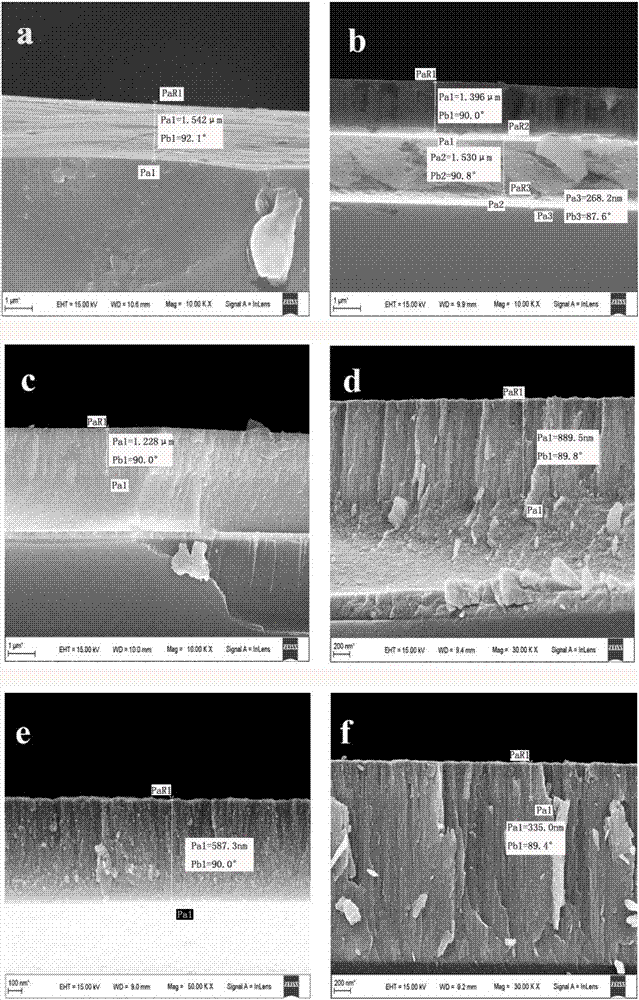

[0113] A method for preparing a tantalum oxide film by DC magnetron sputtering, comprising the following steps: taking a pretreated substrate glass slide and putting it into a reaction chamber of a magnetron sputtering apparatus; 99.95% pure Ar as working gas and 99.95% pure O 2 As a reactive gas, the volume ratio of the working gas to the reactive gas is 14:6; adjust the sputtering working pressure to 2.3Pa, set the sputtering power to 60W, and sputter the Ta target, which is high-purity tantalum with a purity of 99.95%. , the sputtering time was 5min, and a TaOx film was obtained on the substrate.

Embodiment 2

[0115] A method for preparing a tantalum oxide film by a DC magnetron sputtering method, comprising the following steps: taking a pretreated substrate ITO glass and putting it into a reaction chamber of a magnetron sputtering apparatus; after the reaction chamber is evacuated, it is filled with pure 99.95% Ar as working gas and 99.95% O 2 As a reactive gas, the volume ratio of the working gas to the reactive gas is 16:2; adjust the sputtering working pressure to 2.3Pa, set the sputtering power to 70W, and sputter the Ta target, which is high-purity tantalum with a purity of 99.95%. , the sputtering time is 20min, and a TaOx film is obtained on the substrate.

Embodiment 3

[0117]A method for preparing a tantalum oxide film by a DC magnetron sputtering method, comprising the following steps: taking the base material ITO glass and washing away the attached coarse impurities with deionized water, then immersing the base material in acetone, and ultrasonicating the base material at 70 Hz After drying for 10 minutes, put it into a UV cleaning machine and run it for 18 minutes; then immerse the substrate in absolute ethanol, ultrasonicate at 70 Hz for 10 minutes, and dry it. Take the pretreated substrate and put it into the reaction chamber of the magnetron sputtering apparatus. After the reaction chamber is evacuated, it is filled with Ar with a purity of 99.95% as the working gas and O with a purity of 99.95%. 2 As a reactive gas, the volume ratio of the working gas to the reactive gas is 16:4; adjust the sputtering working pressure to 2.3Pa, set the sputtering power to 80W, and sputter the Ta target, which is high-purity tantalum with a purity of 99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com