Silver-copper alloy target material and preparation method thereof

A technology of silver-copper alloy and target material, which is applied in the field of sputtering target material, can solve the problem of uneven target grain size and achieve the effect of uniform thickness and fast sputtering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

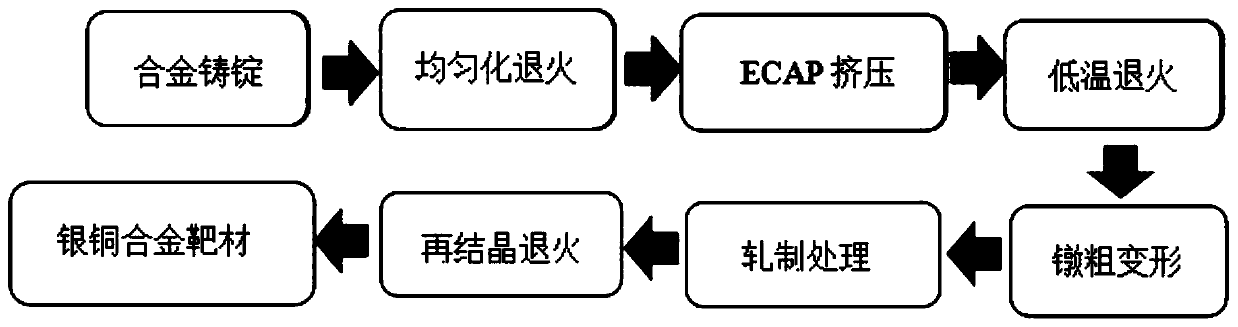

[0030] The invention provides a method for preparing a silver-copper alloy target, comprising the following steps:

[0031] Melting copper and silver under a protective atmosphere to obtain a liquid alloy;

[0032] performing spray deposition treatment on the liquid alloy to obtain a silver-copper alloy ingot;

[0033] The silver-copper alloy ingot is subjected to homogenization annealing, ECAP extrusion, low-temperature annealing, upsetting deformation and rolling in sequence to obtain a silver-copper alloy rough ingot;

[0034] The silver-copper alloy rough ingot is subjected to recrystallization annealing treatment to obtain a silver-copper alloy target material.

[0035] In the invention, copper and silver are smelted under a protective atmosphere to obtain a liquid alloy.

[0036] In the present invention, copper and silver are preferably added to the integrated smelting and spraying equipment, and the silver is loaded into the hopper. When the vacuum degree of the inte...

Embodiment 1

[0054] (1) Select copper with a purity of 99.999% and silver with a purity of 99.99%. According to the ratio of 99.0% by mass of copper and 1.0% by mass of silver, the two are added to the integrated smelting and spraying equipment, and the silver is first loaded In the hopper, when the vacuum degree is 0.8Pa, start to turn on the electricity and heat up, and when the temperature rises to 1190°C, then add silver to melt into a liquid alloy;

[0055] (2) In an inert atmosphere, the liquid alloy flows out through the guide tube, is crushed by high-speed argon at the outlet of the nozzle, atomized into dispersed liquid particles, and directly sprayed onto the substrate, solidified to form an ingot. At this time, the inert gas pressure is set to 0.8MPa, and the gas flow rate is 29L / s;

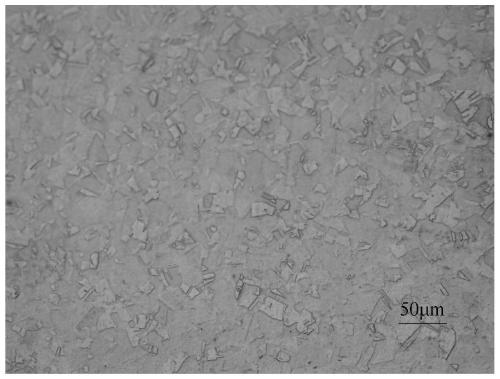

[0056] (3) Carry out high-temperature homogenization annealing on the ingot, the temperature is controlled at 700°C, and keep warm for 2 hours; carry out 5 passes of ECAP extrusion treatment on the...

Embodiment 2

[0062] (1) Select copper with a purity of 99.999% and silver with a purity of 99.99%. According to the ratio of 99.5% by mass of copper and 0.5% by mass of silver, the two are added to the integrated smelting and spraying equipment, and the silver is first loaded In the hopper, when the vacuum degree is 0.6Pa, the temperature is turned on, and when the temperature rises to 1180°C, silver is added to melt into a liquid alloy;

[0063] (2) In an inert atmosphere, the liquid alloy flows out through the guide tube, is crushed by high-speed argon at the outlet of the nozzle, atomized into dispersed liquid particles, and directly sprayed onto the substrate, solidified to form an ingot. At this time, the pressure of the inert gas is set to 0.9MPa, and the gas flow rate is 29L / s;

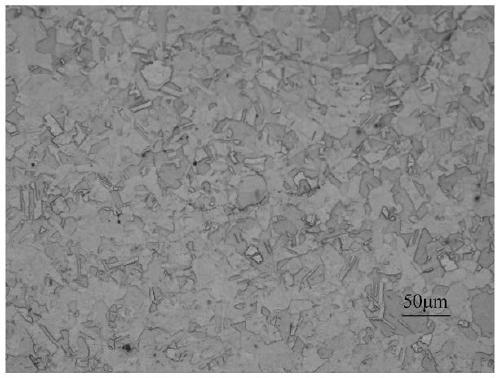

[0064] (3) Perform high-temperature homogenization annealing on the ingot, the temperature is controlled at 650°C, and keep warm for 2.5 hours; perform 4-pass ECAP extrusion treatment on the block ingot, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com