Tin oxide target and preparation method thereof

A tin oxide and target technology, applied in the field of tin oxide target and its preparation, can solve the problems of slow sputtering rate, low compaction rate of SnO target, poor thermal stability of SnO powder, etc., and improve the sputtering rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

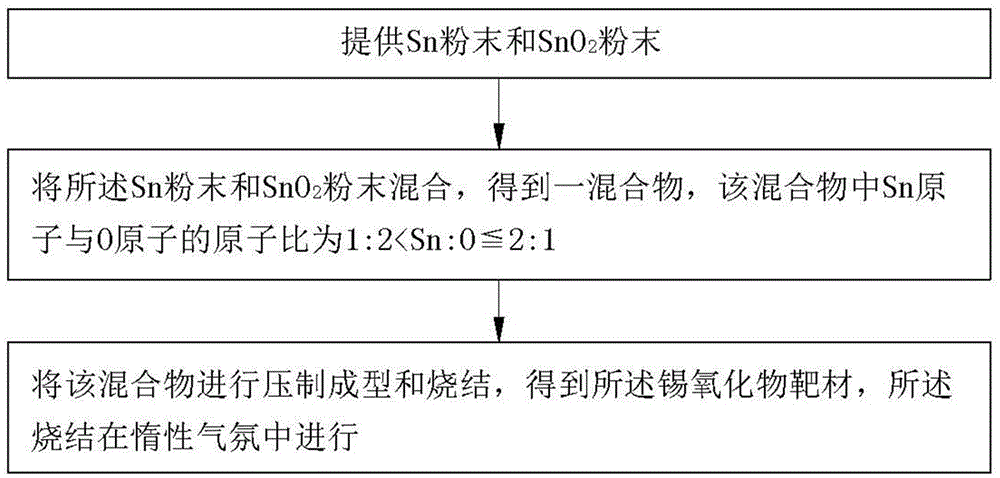

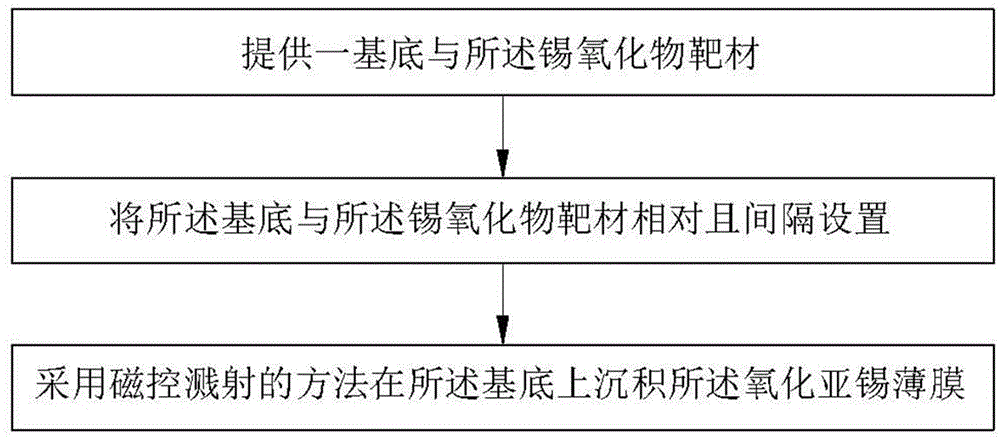

[0025] The embodiment of the present invention further provides a method for preparing the tin oxide target, including:

[0026] S11, provide Sn powder and SnO 2 powder;

[0027] S12, the Sn powder and SnO 2 Mixing the powders to obtain a mixture, the atomic ratio of Sn atoms to O atoms in the mixture is 1:2<Sn:O≦2:1; and

[0028] S13, performing press molding and sintering on the mixture to obtain the tin oxide target, and the sintering is performed in an inert atmosphere.

[0029] In step S11, the Sn powder and SnO 2 The purity of the powder is preferably 3N (99.9% by mass) to 5N (99.999% by mass). The Sn powder and SnO 2 The mass ratio of the powders is regulated according to the atomic ratio of Sn atoms to O atoms in the mixture. In one embodiment, the Sn powder and SnO 2 The mass ratio of the powder is 0.4~1.2. At this time, the atomic ratio of Sn atoms to O atoms in the tin oxide target is 1.5:2≦Sn:O≦2.5:2.

[0030] In step S12, the Sn powder and SnO 2 The metho...

Embodiment 1

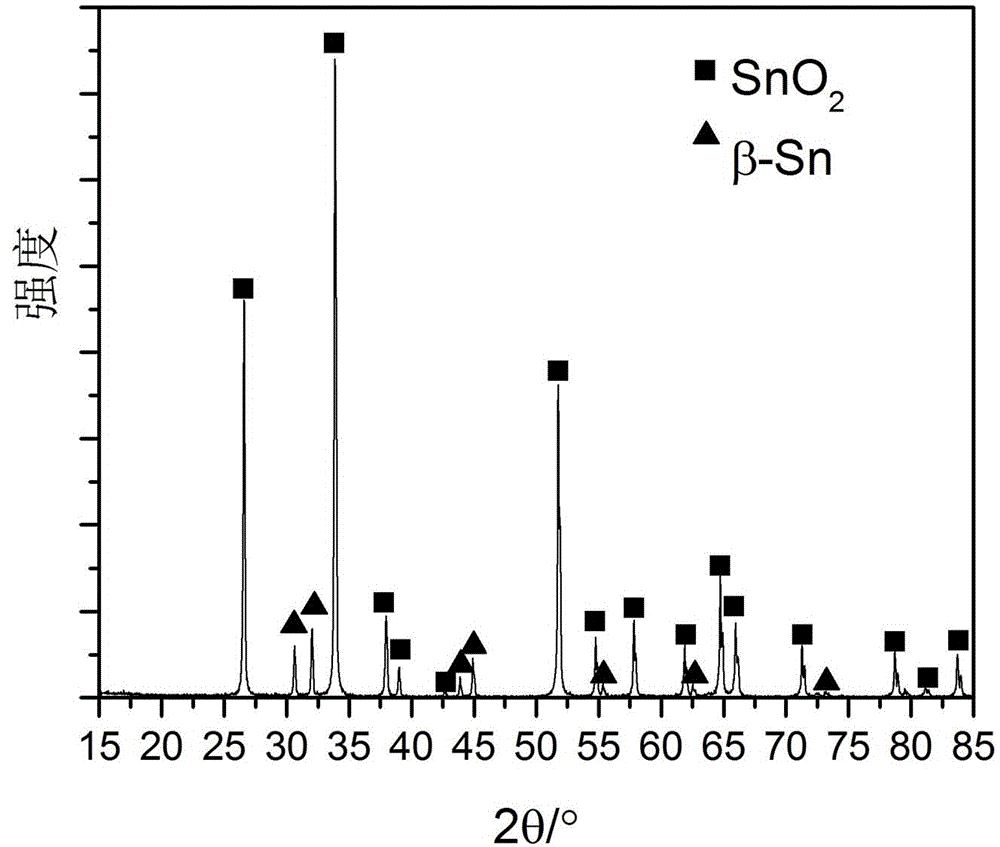

[0051] Weigh 240g of Sn powder with a purity of 5N, SnO 2 Powder 250g, put into the ball mill jar and mix. The ball milling medium is selected as absolute ethanol, the ball milling speed is 200 rpm, and the ball milling time is 10 h. After ball milling, dry under the protection of Ar gas with a pressure of 1 atm and a purity of 5N for 1 h. After sintering, the powder was put into a hot-pressed sintering furnace, and sintered in a high-purity Ar gas atmosphere with a sintering pressure of 50 MPa, a sintering temperature of 300 °C, a heating rate of 15 °C / min, and a sintering time of 4 h. After the sintering is completed, the tin oxide target is obtained by cooling to room temperature with the furnace. The density ratio of the tin oxide target is greater than 85%. The tin oxide target is used for magnetron sputtering, which has easy arc starting and stable sputtering. image 3 Shown is the XRD spectrum of the obtained target sample.

Embodiment 2

[0053] Weigh 160g of Sn powder with a purity of 5N, SnO 2 Powder 160g, put into ball mill jar and mix. The ball milling medium is selected as absolute ethanol, the ball milling speed is 400rpm, and the ball milling time is 20h. After ball milling, the powder was dried under atmospheric pressure for 1 h. The tin oxide target was prepared by constant pressure sintering, and the powder was put into a common press with a pressure of 70MPa and a holding time of 30min. Put it into the sintering furnace after demoulding, in high-purity N 2 The sintering was carried out in an air atmosphere, the sintering temperature was 400°C, the heating rate was 10ºC / min, and the sintering time was 8h. After sintering, the furnace was cooled to room temperature for sampling. The target density rate is greater than 80%. The tin oxide target is used for medium-frequency AC magnetron sputtering, and the arc is easy to start and the sputtering is stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com