Middle and low-vacuum magnetron sputtering target cathode

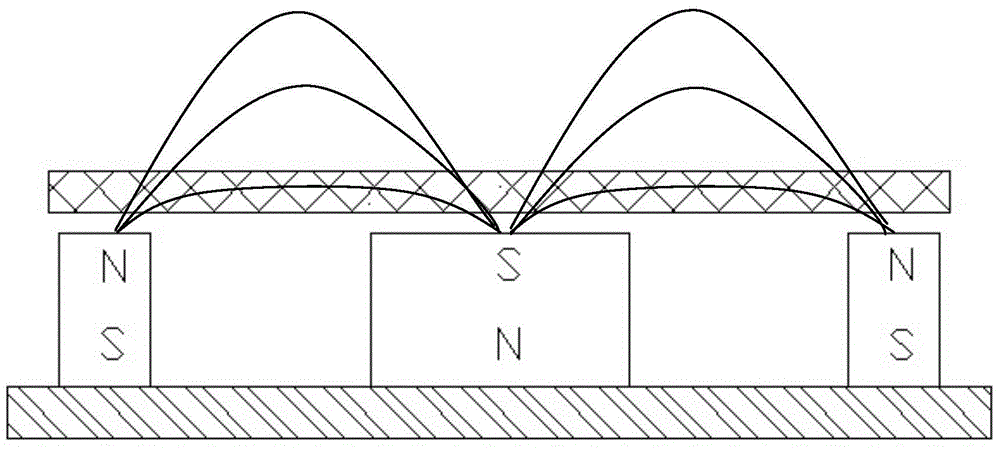

A magnetron sputtering, target cathode technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problem of high difficulty, high technical requirements for wire cutting and welding, and is not suitable for large-scale promotion, etc. problems, to achieve the effect of improving utilization and life, uniform and adjustable particle size, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

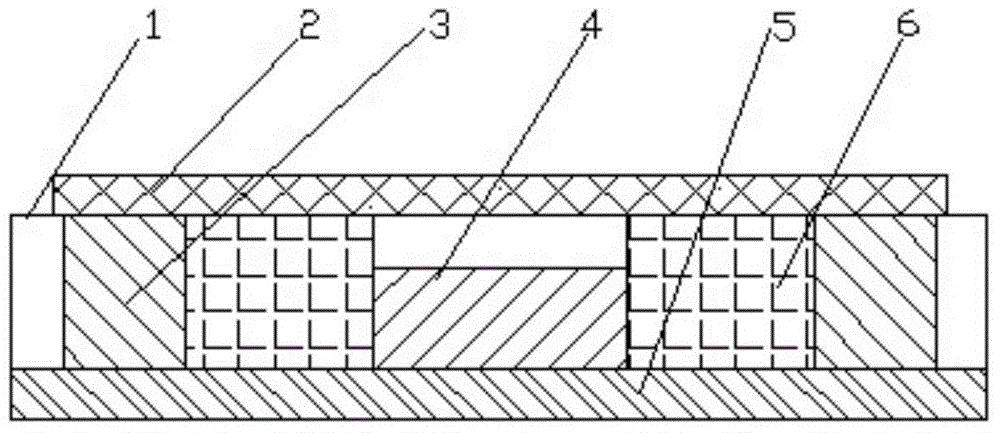

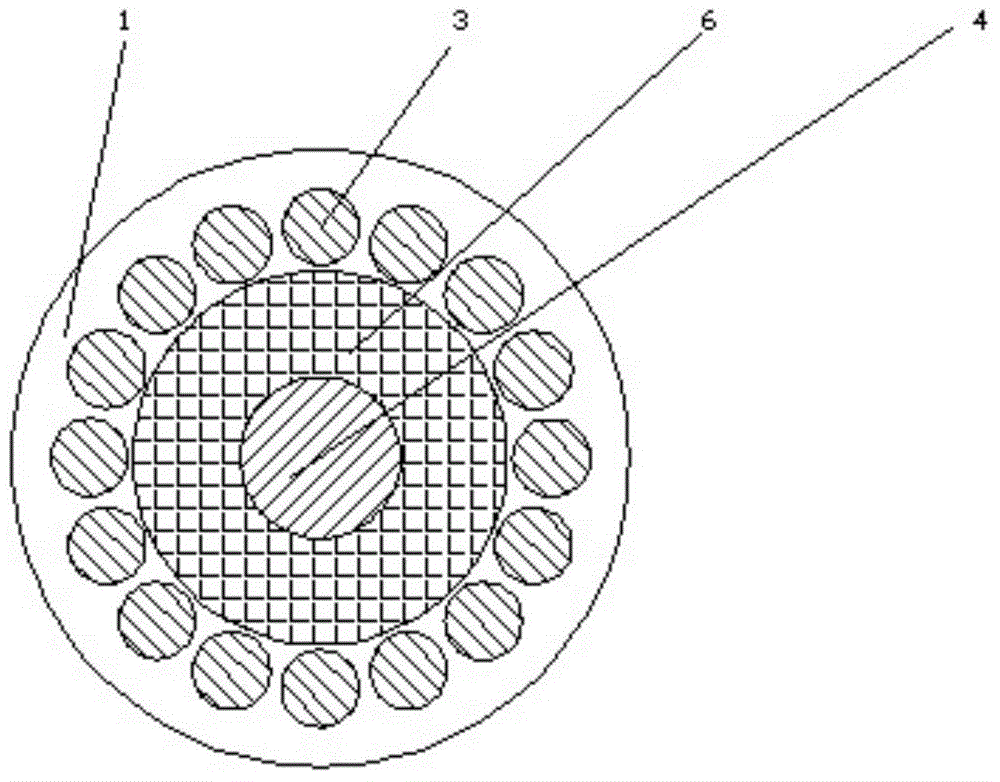

Embodiment 1

[0043] Embodiment 1 of the present invention uses the magnetron sputtering target cathode for medium and low vacuum designed by the present invention to carry out magnetron sputtering, wherein, the diameter of the outer magnet is 8mm, the height is 15mm, and the number of outer magnets is 20; The diameter of the magnet is 24mm, and the height is 14mm; the thickness of the target 2 is 5mm, and the composition is Al; the sputtering power is 80W, the working pressure is 80Pa, and the sputtering deposition time is 1.5h.

Embodiment 2

[0045] Embodiment 2 of the present invention adopts the magnetron sputtering target cathode for medium and low vacuum designed by the present invention to carry out magnetron sputtering, wherein, the diameter of the outer magnet is 14 mm, the height is 15 mm, and the number of outer magnets is 13; The diameter of the magnet 4 is 24mm, and the height is 5mm; the thickness of the target 2 is 0.5mm, and the composition is Fe 50 co 50 ; The sputtering power is 80W, the working pressure is 80Pa, and the sputtering deposition time is 1.5h.

Embodiment 3

[0047] Embodiment 3 of the present invention is to use the magnetron sputtering target cathode for medium and low vacuum designed by the present invention to carry out magnetron sputtering, wherein, the diameter of the outer magnet is 12 mm, the height is 15 mm, and the number of outer magnets is 16; The diameter of the magnet 4 is 24mm, and the height is 10mm; the thickness of the target 2 is 3mm, and the composition is Fe 50 Ni 50 ; The sputtering power is 80W, the working pressure is 80Pa, and the sputtering deposition time is 1.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com