Method for preparing metal ion-doped titanium dioxide target material and target material thereby

A technology of titanium dioxide and metal ions, which is applied in the preparation of metal ion-doped titanium dioxide targets and the field of targets obtained therefrom, can solve the problem that the amount of metal ion doping is difficult to control accurately, the amount of metal ion doping is difficult to accurately control, Limiting the wide application of magnetron sputtering technology and other issues, to achieve the effects of easy mass production, high uniformity, and good sol stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

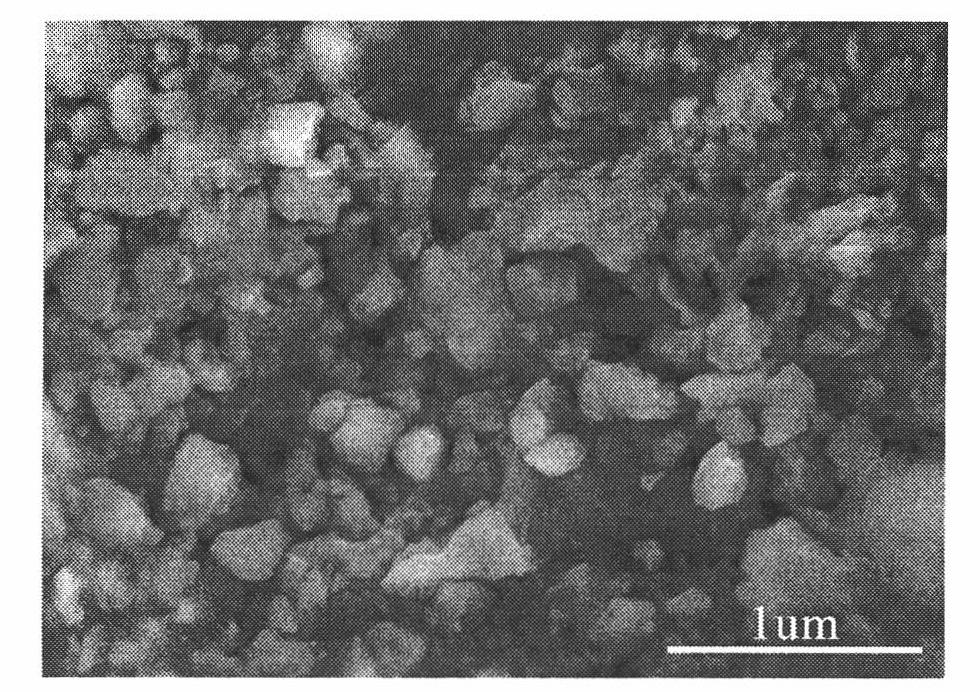

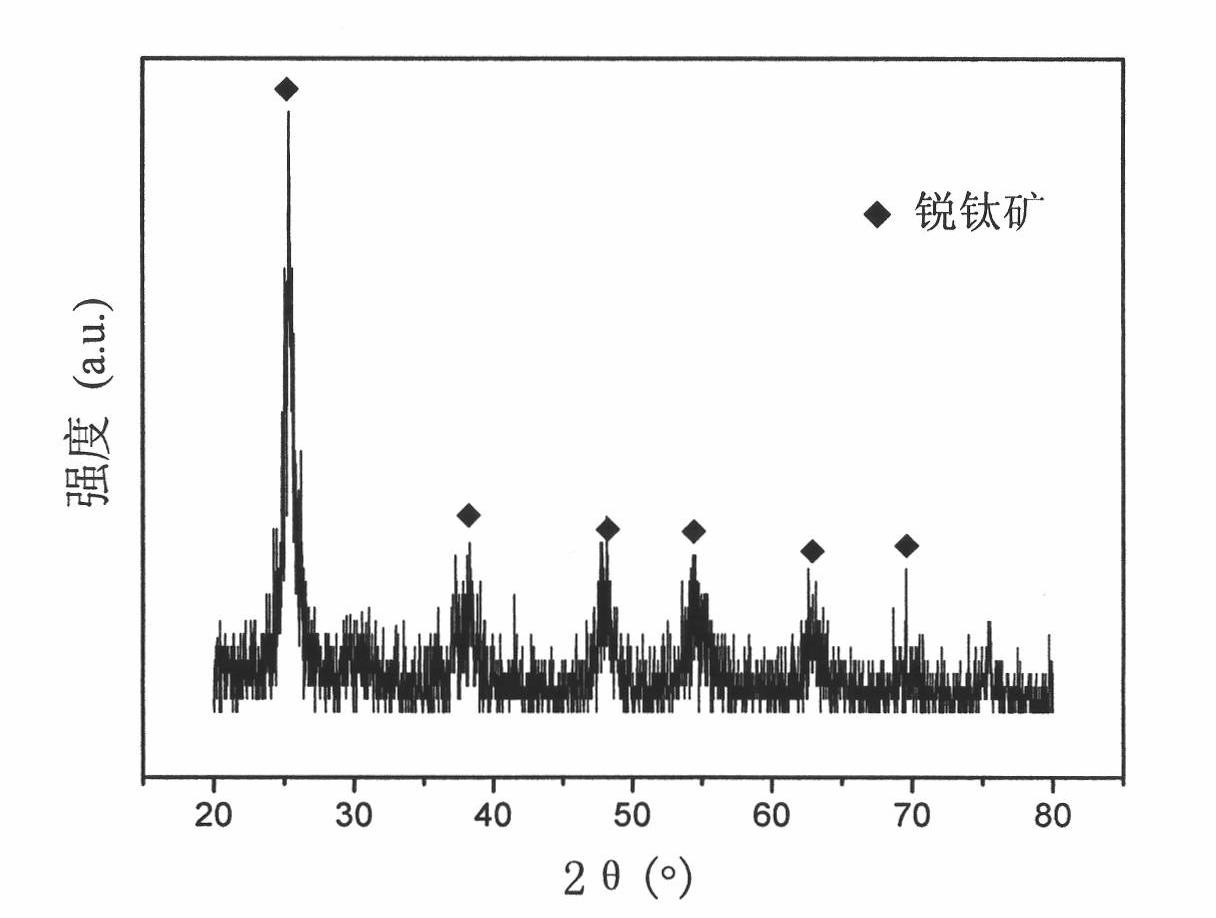

[0031] Example 1: First, mix n-butyl titanate with absolute ethanol and deionized water in a volume ratio of 1:2:0.1, and stir at room temperature at a speed of 1000 rpm; then add zinc nitrate-containing Mass percent is 10% dehydrated alcohol solution, makes the mol ratio of zinc and titanium be 1: 10, forms the sol liquid of ion doping; Add acetic acid and diethanolamine again, make acetic acid, diethanolamine and sol press 1: 1: Mix at a volume ratio of 10, continue to stir for 2 hours, and then seal and age at room temperature for 12 hours; add deionized water to the aged titanium dioxide sol until the gel is completely formed, and then dry the gel at 80°C for 12 hours. Hours, a yellow xerogel is formed; then the titanium dioxide powder obtained by mechanically grinding the xerogel is mixed with the binder evenly, and put into the mold with an axial loading rate of 20KN / min to an axial pressure of 50MPa Keep it under pressure for 10 minutes for briquetting, and unload at a ...

Embodiment 2

[0032] Example 2: First, n-butyl titanate was mixed with absolute ethanol and deionized water at a volume ratio of 1:5:0.2, and stirred at a temperature of 30°C at a speed of 800 rpm; then adding Ferric nitrate and copper nitrate mass percent are 20% dehydrated alcohol solution, make the molar ratio of iron, copper and titanium be 1: 1: 15, form the sol liquid of two kinds of metal ions mixed doping; Add oxalic acid and dimethyl Base ethanolamine, make oxalic acid, dimethylethanolamine and sol mix by the volume ratio of 1: 1: 15, continue to stir for 5 hours and seal and age at room temperature for 24 hours; Add deionized water to the titanium dioxide sol after aging The gel is completely formed, and then the gel is dried at 100°C for 12 hours to form a yellow xerogel; then the titanium dioxide powder obtained by mechanically grinding the xerogel and the binder are mixed and stirred evenly, and placed in In the mold, the loading rate of 30KN / min to the axial pressure of 80MPa ...

Embodiment 3

[0033] Example 3: first mix n-butyl titanate with absolute ethanol and deionized water in a volume ratio of 1:8:0.2, and stir at a temperature of 30°C at a speed of 800 rpm; then add Cerous nitrate mass percent is 20% dehydrated alcohol solution, makes the mol ratio of cerium and titanium be 1: 15, forms the sol liquid of rare earth cerium ion doping; Add citric acid and diethanolamine again, make citric acid, diethanolamine Mix with the sol at a volume ratio of 1:1:10, continue to stir for 8 hours, and then seal and age at room temperature for 24 hours; add deionized water to the aged titanium dioxide sol until the gel is completely formed, and then place the gel in Dry at 100°C for 18 hours to form a yellow xerogel; then mix and stir the titanium dioxide powder obtained by mechanically grinding the xerogel with the binder, and put it into the mold at a loading rate of 50KN / min to Hold the axial pressure of 100MPa for 30min to briquette, and unload at a rate of 100KN / min to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com