Vanadium-based high-temperature solar selective absorption coating and preparation method thereof

An absorbing coating and selective technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of low process deposition rate, long production cycle, complex process, etc., and achieve fast sputtering rate , Reduce equipment cost and production cost, and the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

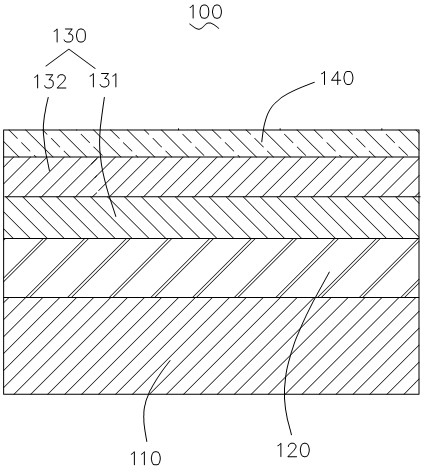

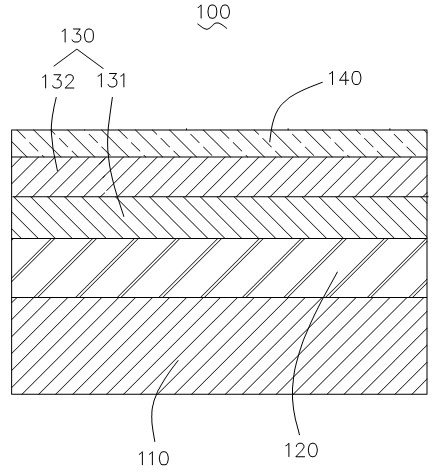

[0041] Embodiment 1, a high-temperature solar energy selective absorption coating 100 is composed of three-layer films, the three-layer film includes a bottom infrared reflection layer 120 , a middle absorption layer 130 and a surface anti-reflection layer 140 . The bottom infrared reflection layer 120 is deposited on the surface of the substrate 110, and the substrate 110 is a stainless steel tube. The middle absorption layer 130 is deposited on the bottom infrared reflection layer 120 , and the surface anti-reflection layer 140 is deposited on the middle absorption layer 130 .

[0042] The bottom infrared reflection layer 120 is composed of a metal V (vanadium) film, and the thickness of the bottom infrared reflection layer 120 is 100-400 nm.

[0043] The intermediate absorption layer 130 includes a first sublayer 131 and a second sublayer 132, and the first sublayer 131 and the second sublayer 132 are both composed of V+SiO 2 In the film composition, the volume percentage ...

Embodiment 2

[0055] Embodiment 2, a high-temperature solar energy selective absorption coating 100 is composed of three layers of film, the three-layer film includes a bottom infrared reflection layer 120 , a middle absorption layer 130 and a surface anti-reflection layer 140 . The bottom infrared reflection layer 120 is deposited on the surface of the substrate 110, and the substrate 110 is a stainless steel tube. The middle absorption layer 130 is deposited on the bottom infrared reflection layer 120 , and the surface anti-reflection layer 140 is deposited on the middle absorption layer 130 .

[0056] The bottom infrared reflection layer 120 is composed of a metal V (vanadium) film, and the thickness of the bottom infrared reflection layer 120 is 100-400 nm.

[0057] The middle absorbing layer 130 includes a first sublayer 131 and a second sublayer 132, and the first sublayer 131 and the second sublayer 132 are both composed of V+Al 2 o 3 In the film composition, the volume percentage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com