Thermally stable leadless high temperature piezoelectric ceramic and preparing method thereof

A high-temperature piezoelectric and thermally stable technology, applied in the field of piezoelectric ceramic materials and their preparation, thermally stable lead-free high-temperature piezoelectric ceramics and their preparation, can solve the problem of insufficient temperature stability of piezoelectric and electromechanical properties and poor electrical properties. To give full play to the problems of potassium and sodium stoichiometry deviation, to achieve excellent piezoelectric coefficient, good temperature stability, mechanical properties and good moisture resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Carry out each step successively according to above-mentioned embodiment mode, wherein

[0041] In step 1, values are selected according to a=0.47, b=0.43, c=0.06, d=0.035, e=0.005, u=0.96, v=0.04, x=0, y=0. The expression of composition is: (Na 0.47 K 0.43 Li 0.06 Ag 0.035 Bi 0.005 )(Nb 0.96 Ta 0.04 )O 3

[0042] In step 2, the calcination temperature is 900°C, and the calcination time is 5h;

[0043] In step 3, the sintering temperature is 1070°C, and the sintering time is 3h;

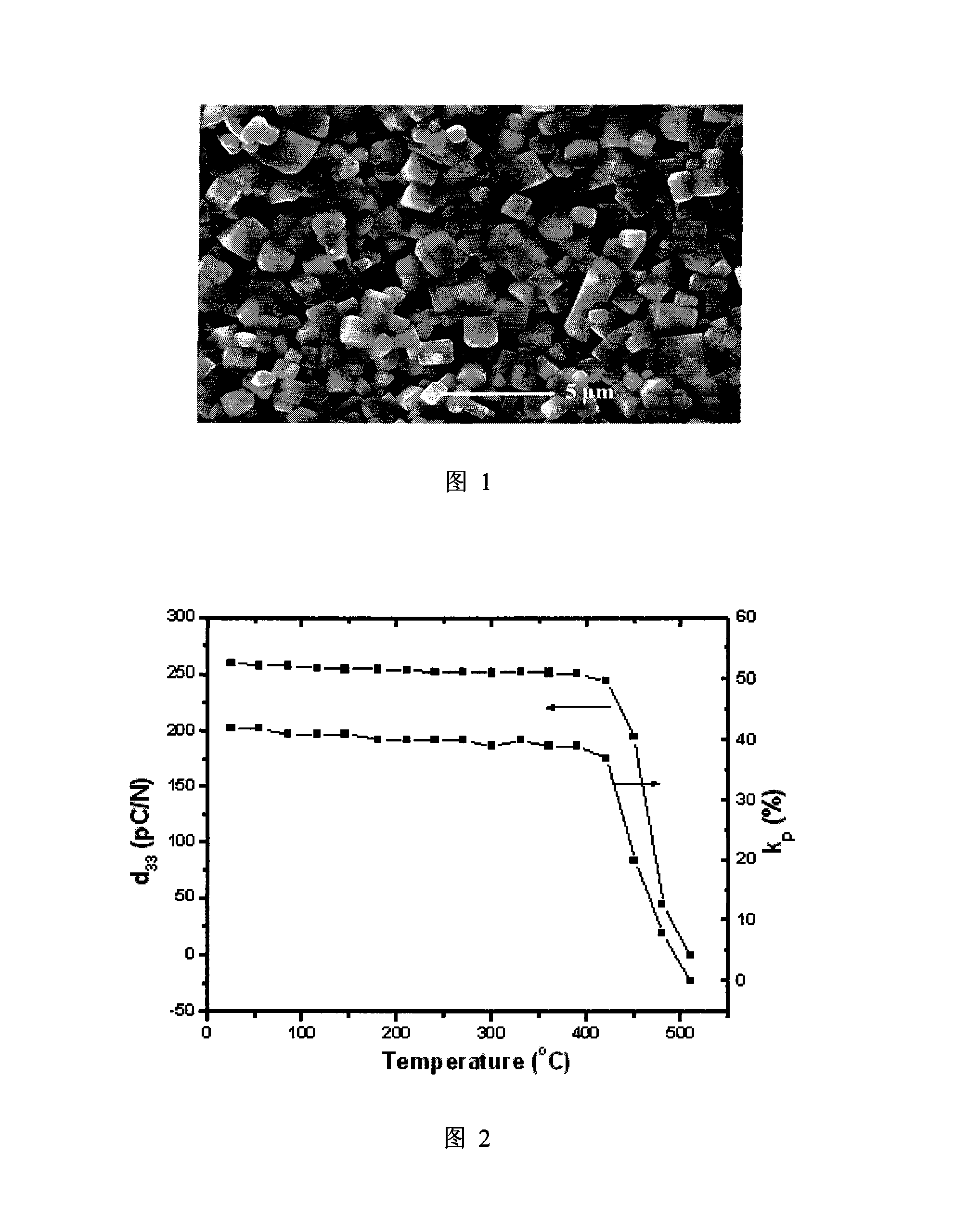

[0044] The scanning electron micrograph of the natural surface of the sample obtained is shown in Figure 1, and other relevant properties are shown in Table 1:

[0045] Table 1

[0046] Density (g / cm 2 )

Embodiment 2

[0047] Embodiment 2: Carry out each step successively according to above-mentioned embodiment mode, wherein

[0048] In step 1, values are selected according to a=0.47, b=0.43, c=0.06, d=0.035, e=0.005, u=0.96, v=0.04, x=0.3%, y=0.2%. The expression of composition is: (Na 0.47 K 0.43 Li 0.06 Ag 0.035 Bi 0.005 )(Nb 0.96 Ta 0.04 )O 3 +0.3wt%MgTiO 3 +0.2wt%CuO

[0049] In step 2, the calcination temperature is 850°C, and the calcination time is 5h;

[0050] In step 3, the sintering temperature is 1050°C, and the sintering time is 3h;

[0051] The piezoelectric coefficient d of the obtained lead-free piezoelectric ceramic sample 33 and the electromechanical coupling coefficient k p The temperature dependence is shown in Figure 2, and other related properties are shown in Table 2:

[0052] Table 2

[0053] Density (g / cm 2 )

Embodiment 3

[0054] Embodiment 3: Carry out each step successively according to above-mentioned embodiment mode, wherein

[0055] In step 1, values are selected according to a=0.47, b=0.43, c=0.06, d=0.035, e=0.005, u=0.96, v=0.04, x=0.4%, y=0.2%. The expression of composition is: (Na 0.47 K 0.43 Li 0.06 Ag 0.035 Bi 0.005 )(Nb 0.96 Ta 0.04 )O 3 +0.4wt%CaTiO 3 +0.2wt%CuO

[0056] In step 2, the calcination temperature is 850°C, and the calcination time is 5h;

[0057] In step 3, the sintering temperature is 1060°C, and the sintering time is 3h;

[0058] The relevant properties of the prepared lead-free piezoelectric ceramic samples are shown in Table 3:

[0059] table 3

[0060] Density (g / cm 2 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com