High-power pulse plasma reinforced composite magnetron sputtering deposition device and application method thereof

A high-power pulsed, magnetron sputtering technology, applied in sputtering, ion implantation, metal material coating, etc. Control the problems of slow sputtering deposition rate and insufficient bonding strength of the coating, so as to improve the ionization rate and the adhesion of the film base, improve the coating efficiency and ion plating effect, and improve the hardness and compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

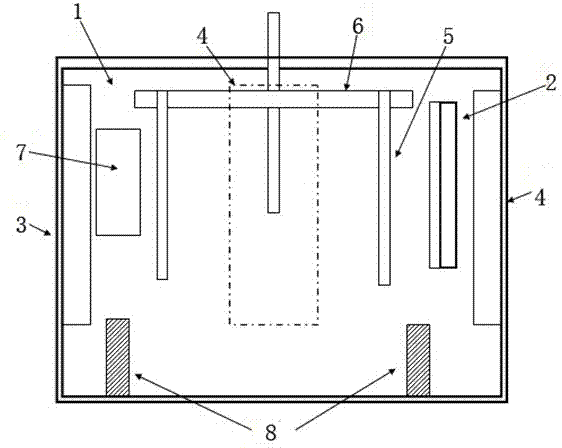

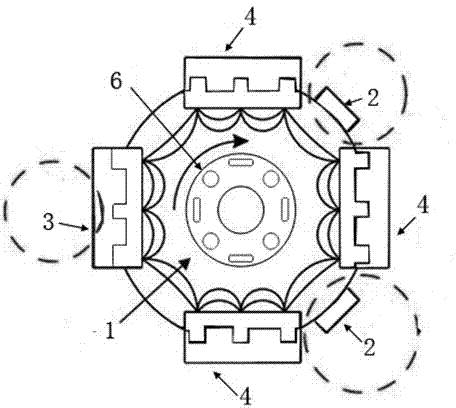

[0025] Such as figure 1 , figure 2 As shown, a high-power pulsed plasma enhanced composite magnetron sputtering deposition device includes a vacuum chamber 1, a magnetron target, a workpiece holder 5 and a rotating support 6;

[0026] The vacuum chamber 1 is a sealed structure, and an air extraction port 7 is opened on it, and the air extraction port 7 is connected with a vacuum pump;

[0027] Such as figure 2 As shown, the magnetron target includes a high-power pulsed magnetron sputtering target 3 and three pulsed DC magnetron targets 4, which are fixed in the vacuum chamber 1 and arranged opposite to each other at 90 degrees, and the layout of the magnetic field is opposite. , forming a closed field; the magnetic field layout of each magnetron target is an unbalanced magnetic field;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com