Ionization-rate-controllable coating device based on high-power impulse magnetron sputtering

A technology of high-power pulse and coating equipment, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of low pulse frequency, low duty cycle, etc., and achieve the reduction of pulse current hysteresis time, Effect of Guaranteed Thin Film Deposition Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

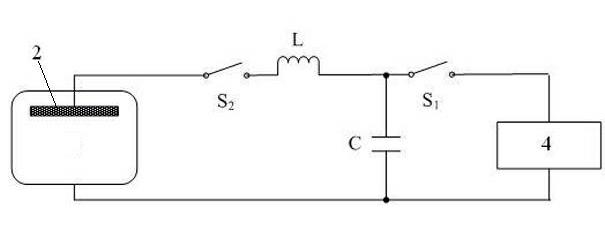

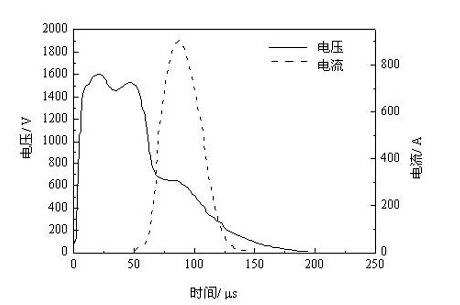

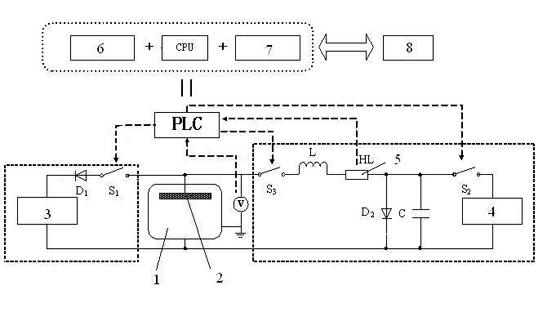

[0024] image 3 It shows the principle diagram of this high-power pulse magnetron sputtering technology with adjustable ionization rate. The system mainly includes: vacuum sputtering system, low-voltage DC power supply system, high-voltage pulse power supply system and PLC central control system. The low-voltage DC power supply system provides low-voltage current for the vacuum system, and the high-voltage pulse power supply system provides high-voltage current for the vacuum system; the PLC central control system controls the vacuum system, low-voltage DC power supply system, and high-voltage pulse power supply system.

[0025] The vacuum sputtering system consists of a vacuum chamber 1, a magnetron sputtering target 2, and a vacuum obtaining device. The low-voltage DC power supply system includes: DC power supplies connected in series 3, electronic switches S 1 And diode D1; used to provide a stable low voltage for the magnetron target; the voltage range of the low-voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com