Multifunctional fully-automatic ion-plating machine for deposition of cutting tool coating and using method of multifunctional fully-automatic ion-plating machine

A multifunctional and fully automatic technology, applied in ion implantation plating, coating, metal material coating process, etc., can solve the problem of low gas ionization rate and target utilization, high incident particle energy, and film roughness Increase and other problems, to achieve the effect of improving utilization rate and gas ionization rate, improving coating quality, and suppressing droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

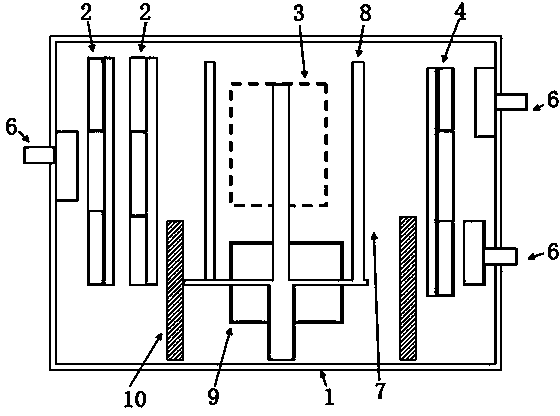

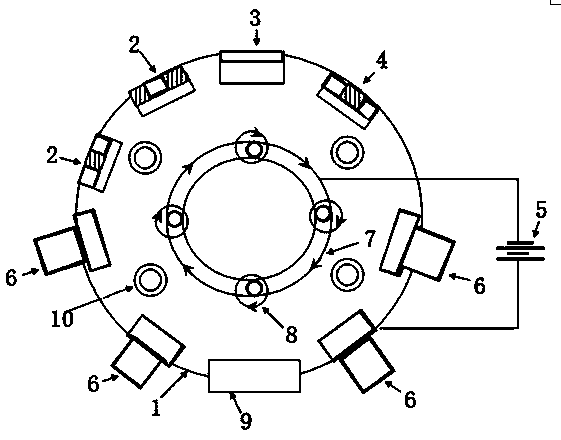

[0029] Such as figure 1 , figure 2 As shown, a multi-functional automatic ion coating machine for tool coating deposition, including a vacuum chamber 1, a bipolar pulse magnetron sputtering target 2, a rectangular anode layer gas ion source 3, a high-power pulse magnetron sputtering Radiation source 4, bias power supply 5, cathode arc source 6, workpiece holder 7 and support 8;

[0030] Such as figure 1 As shown, the vacuum chamber 1 is a sealed structure, and an air extraction port 9 is provided on it. The bipolar pulse magnetron sputtering target 2, the anode layer gas ion source 3, the high-power pulse magnetron sputtering source 4, and the cathode The arc source 6 and the workpiece frame 7 are fixed in the vacuum chamber 1, and the support 8 is connected with the workpiece frame 7;

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com