High-power pulsed magnetron sputtering CrAlSiN nano-composite coating and preparation method thereof

A nanocomposite coating and coating technology, which is applied in coating, sputtering plating, metal material coating technology, etc., can solve the problems of low fracture toughness, inability to meet advanced processing technology requirements, poor high temperature oxidation resistance, etc. , to achieve the effect of dense structure, fine grain, good high temperature thermal stability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, a CrAlSiN nanocomposite coating was prepared on a polished high-speed steel sheet by high-power pulse and DC pulse co-sputtering technology, and the size of the high-speed steel sample was 25×30×1 mm. The substrates were ultrasonically cleaned in acetone, alcohol, and distilled water for 20 min each, and then cleaned with high-purity N 2 Dry it, and then place it on the sample holder facing the target in a high-power pulse and DC pulse co-sputtering coater. The rotation speed of the turntable is selected as 30 r / min, and the distance between the target and the base is 80 mm. The targets are made of pure metals Cr, Al and Si (all with a purity of 99.99 wt.%), and the working gas and reaction gas are made of high-purity Ar and N respectively. 2 (The purity is 99.999%).

[0021] First, the background vacuum of the vacuum chamber is evacuated to 1.0×10 -3 Above Pa; turn on the heating system, raise the temperature to 300 ℃, and wait until the vacuum degr...

Embodiment 2

[0026] In this example, a CrAlSiN nanocomposite coating is deposited on a polished cemented carbide substrate YG8, and the sample size is 19×19×2 mm. The substrates were ultrasonically cleaned in acetone, alcohol, and distilled water for 20 min each, and then cleaned with high-purity N 2 Blow-dry, the rotation speed of the turret is selected as 30 r / min, and the distance between the target and the base is 80 mm. The targets are made of pure metal Cr and Al (both with a purity of wt. 99.9%), and the working gas and reaction gas are made of Ar and N respectively. 2(The purity is 99.999%). In the process of depositing the CrAlSiN nanocomposite coating in this embodiment, the Cr target, the Al target and the Si target power supply, the power is 1KW, 1.0KW, 0.6KW respectively, and other process parameters are the same as the embodiment 1.

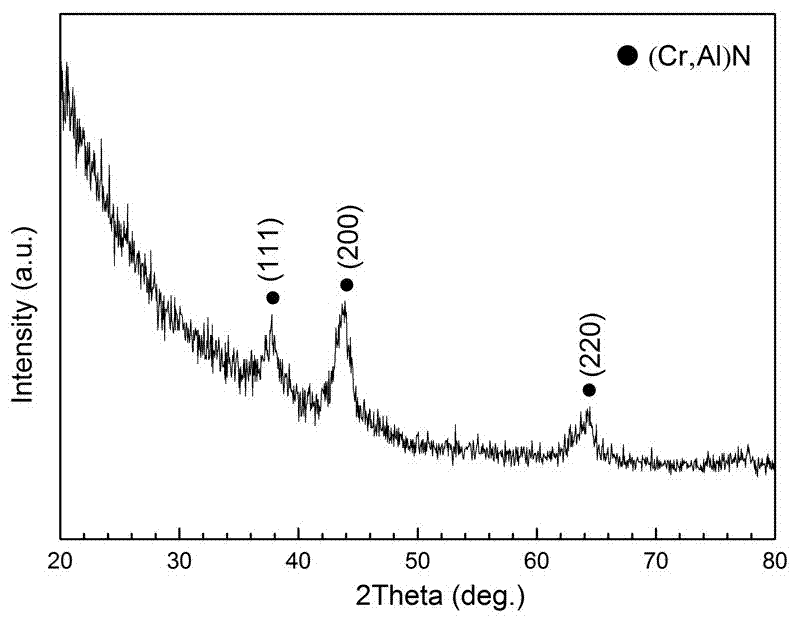

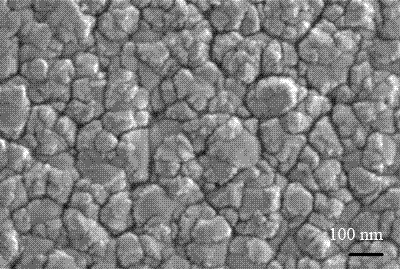

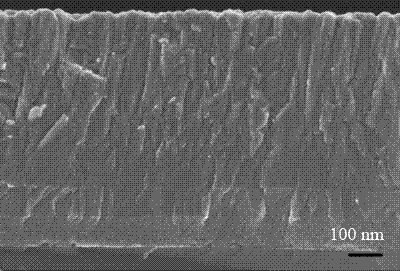

[0027] The phase composition and structure of the CrAlSiN coating prepared under the process of the present invention are the same as those o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com