Coating for metal bipolar plates of fuel cells and preparation technology

A metal bipolar plate and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of low manufacturing cost, poor mechanical strength, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

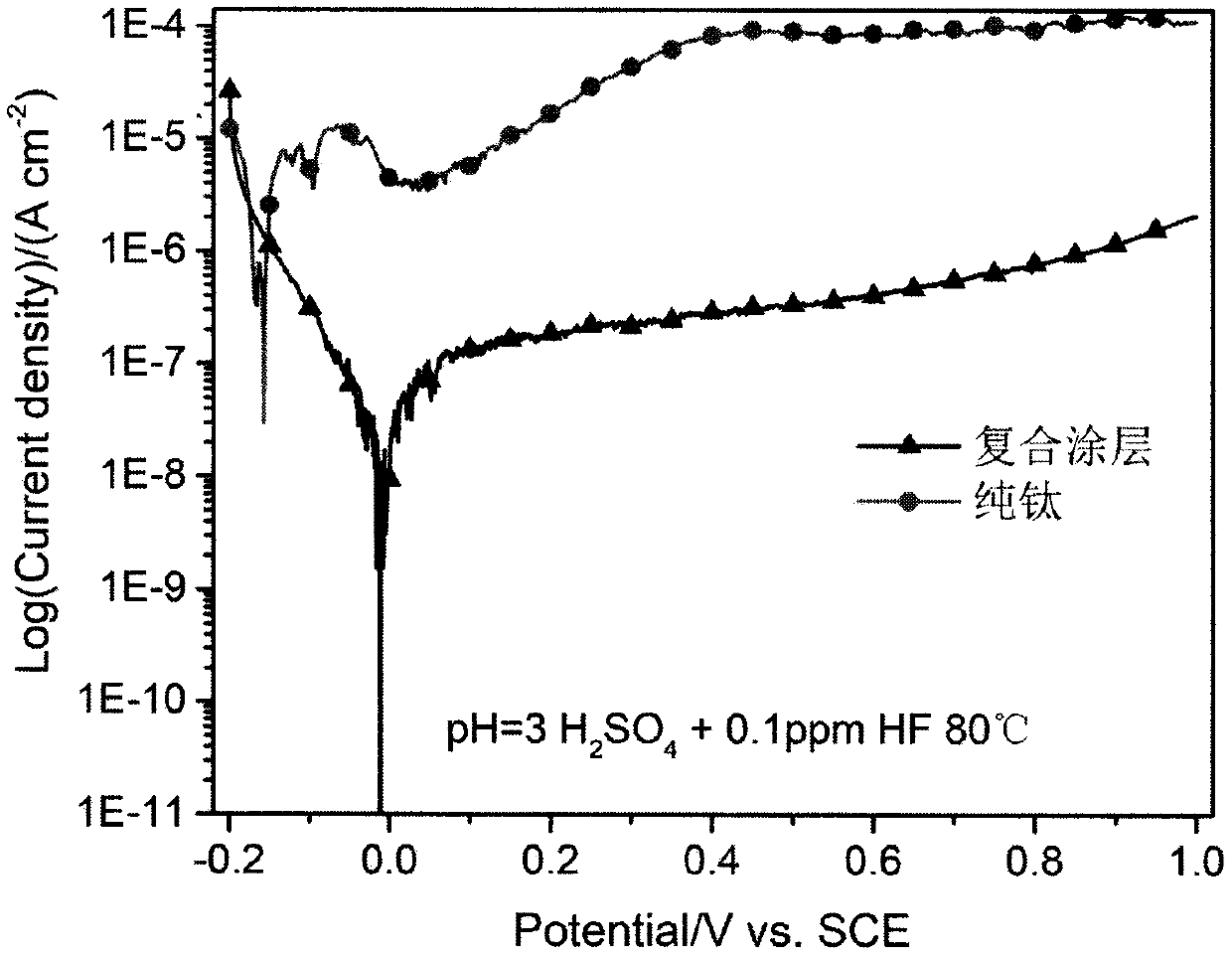

Problems solved by technology

Method used

Image

Examples

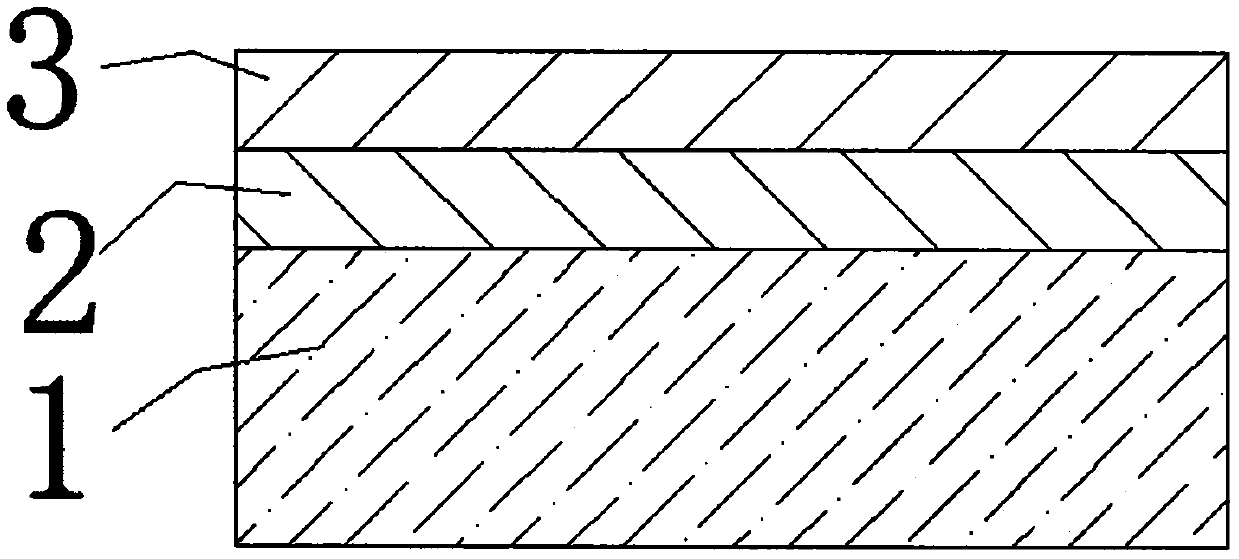

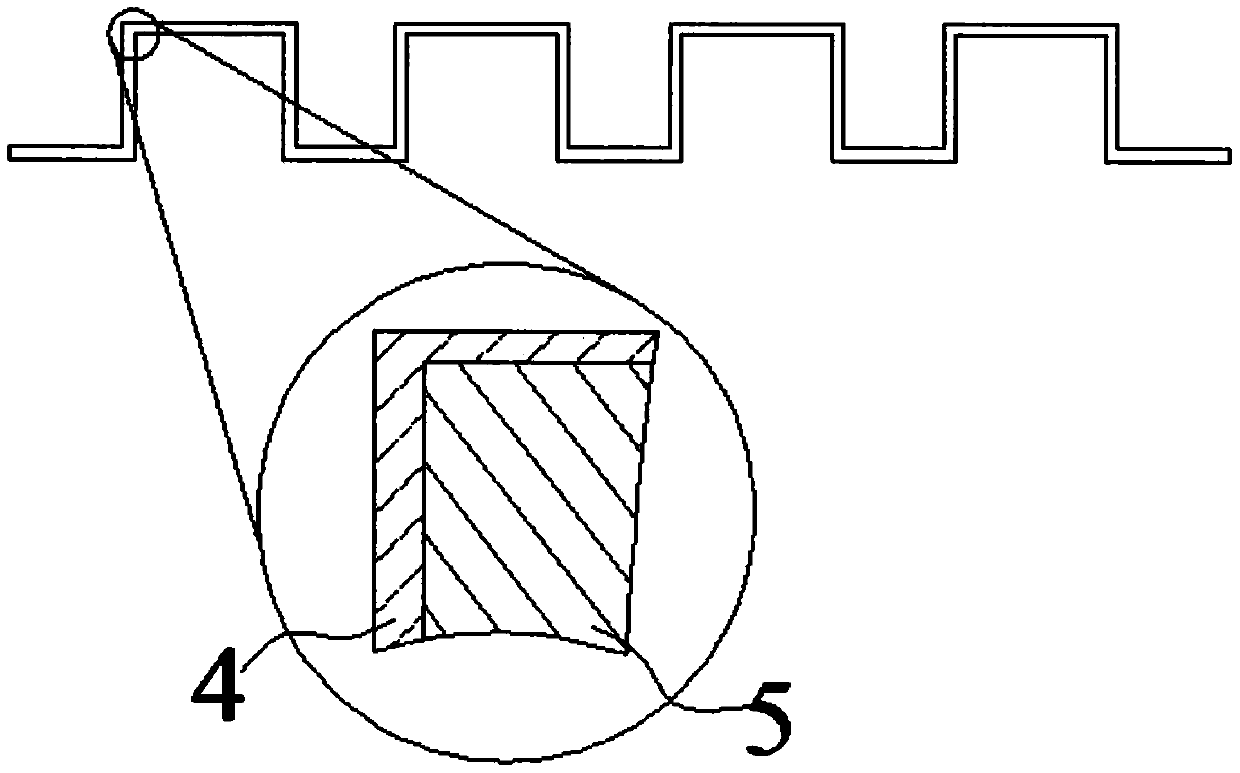

Embodiment Construction

[0030] In one embodiment, after the vacuum chamber is sealed, it is evacuated to 3×10 -3 Pa, the first step is argon ion etching (voltage 1000V, current 1A), time 3min; the second step is composite transition layer deposition, high-purity Ti target (≥99.5%, voltage 300-0V, current 30-0A), high-purity Nitrogen (≥99.99%, 100-0sccm), high-purity graphite target (≥99.5%, voltage 1200V, current 5-30A), time 1min, the third step uses HIPIMS sputtering high-purity graphite target (≥99.5%, voltage 1200V , current 30A), time 10min, the thickness of the formed coating is 0.2 microns.

[0031] In another embodiment, after the vacuum chamber is sealed, it is evacuated to 3×10 -3Pa, the first step is argon ion etching (voltage 1200V, current 1A), time 3min; the second step is composite transition layer deposition, high-purity Ti target (≥99.5%, voltage 600-0V, current 20-0A), high-purity Nitrogen (≥99.99%, 80-0sccm), high-purity graphite target (≥99.5%, voltage 1000V, current 5-30A), tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com