Preparation method of matrix surface nano compound Me-Si-N superhard coating

A nano-composite, me-si-n technology, applied in the field of preparation of nano-composite Me-Si-N superhard coating on the surface of the substrate, can solve the problems of rough film surface, low film hardness and low metal ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the high-speed steel is used as the substrate, and the TiSiN nanocomposite coating is deposited on the surface of the substrate by using high-power pulsed magnetron sputtering technology. The specific preparation process is as follows.

[0033] (1) Put the cleaned and dried substrate into the vacuum chamber until the air pressure in the chamber is 3×10 -3 At Pa, argon gas was introduced into the vacuum chamber so that the chamber pressure was 8.0mTorr, the substrate pulse negative bias was -400V, and the substrate was etched for 20 minutes by glow discharge;

[0034] (2) After the etching is completed, Ar is introduced into the cavity, so that the cavity pressure is 2mTorr, the high-power pulse magnetron sputtering source is turned on, and the alloy target TiSi target is deposited by high-power pulse magnetron sputtering to deposit the TiSi transition layer , the substrate negative bias voltage is -300V, the sputtering DC current is 2A, the pulse con...

Embodiment 2

[0040] In this embodiment, the substrate is exactly the same as that in Embodiment 1, and a TiSiN nanocomposite coating is deposited on the surface of the substrate by high-power pulse magnetron sputtering technology, and the specific preparation process is as follows.

[0041] (1) Exactly the same as step (1) in Example 1;

[0042] (2) It is basically the same as step (2) in Example 1, the difference is: when using the high-power pulse magnetron sputtering alloy target TiSi target to deposit the TiSi transition layer, the negative bias of the substrate is -300V, and the sputtering The DC current is 1A, the pulse constant voltage is 450V, the pulse frequency is 40Hz, and the pulse width is 80 microseconds;

[0043] (3) It is basically the same as step (2) in Example 1, the difference is: use high-power pulse magnetron sputtering alloy target TiSi target to deposit TiSiN nanocomposite coating; substrate negative bias is -100V, sputtering The pulse constant current is 1A, the p...

Embodiment 3

[0048] In this embodiment, the high-speed steel is used as the substrate, and the CrSiN nano-composite coating is deposited on the surface of the substrate by high-power pulsed magnetron sputtering technology, and the specific process is as follows.

[0049] (1) Put the cleaned and dried substrate into the vacuum chamber until the air pressure in the chamber is 3×10 -3 At Pa, argon gas was introduced into the vacuum chamber so that the chamber pressure was 8.0mtorr, the substrate pulse negative bias was -400V, and the substrate was etched for 20 minutes by glow discharge;

[0050] (2) After the etching is completed, Ar is introduced into the cavity, so that the cavity pressure is 2mTorr, the high-power pulse magnetron sputtering source is turned on, and the CrSi transition layer is deposited by using the high-power pulse magnetron sputtering metal target CrSi target, The substrate negative bias is -300V, the sputtering pulse constant current is 2A, the pulse constant voltage i...

PUM

| Property | Measurement | Unit |

|---|---|---|

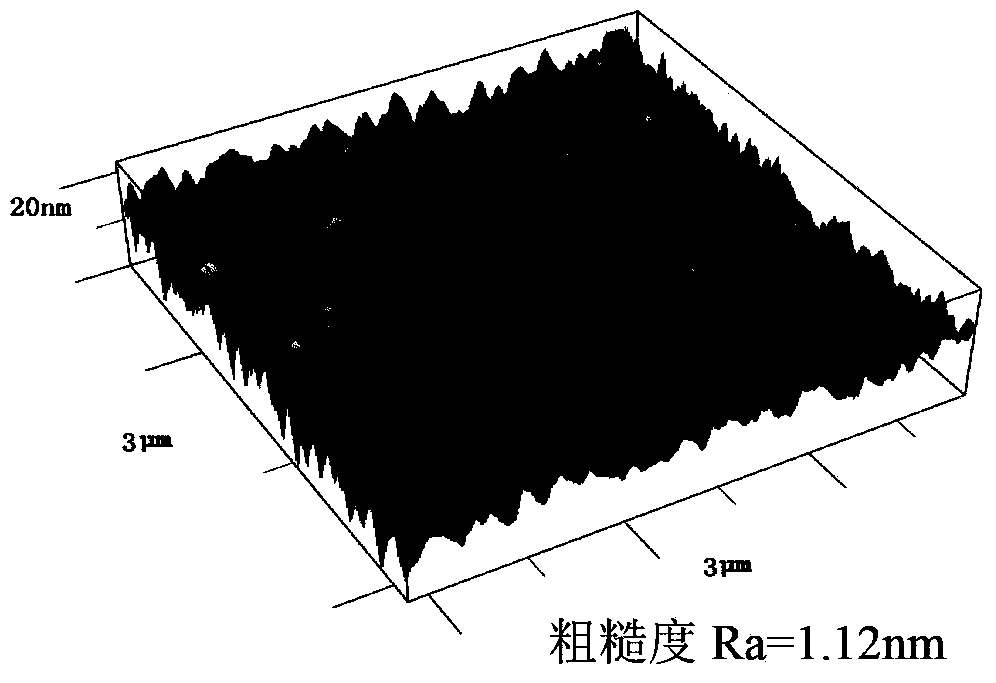

| Surface roughness | aaaaa | aaaaa |

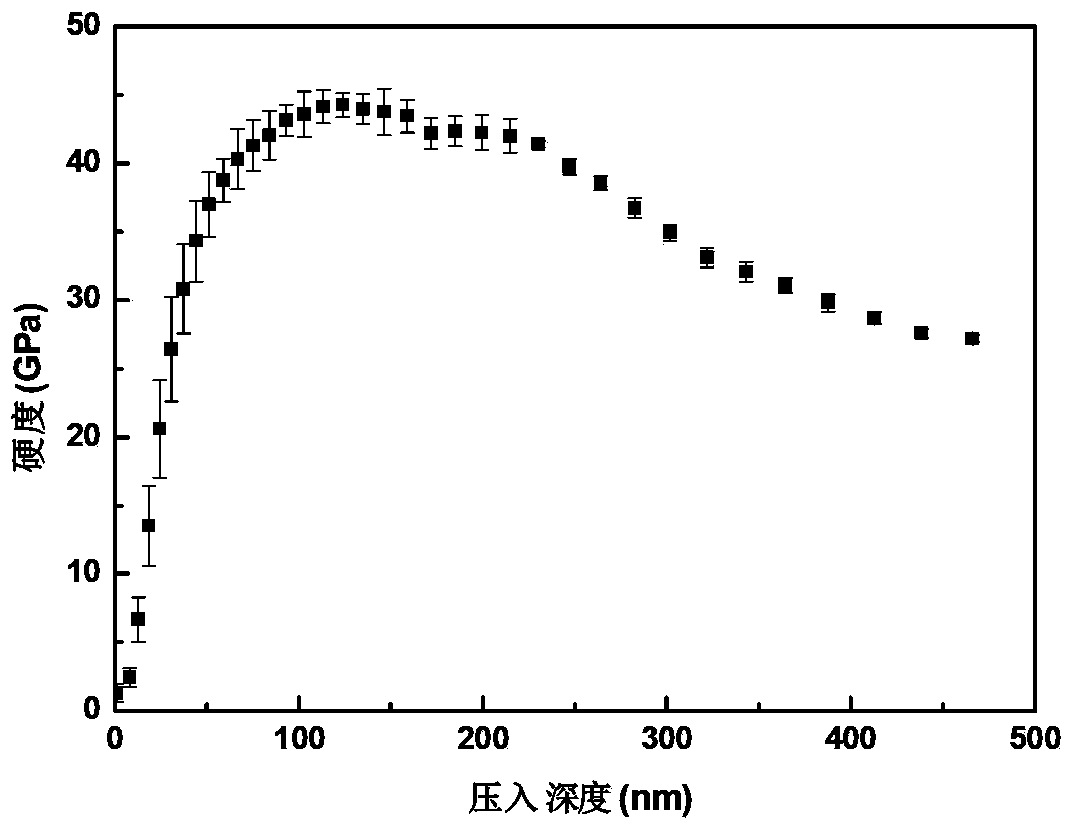

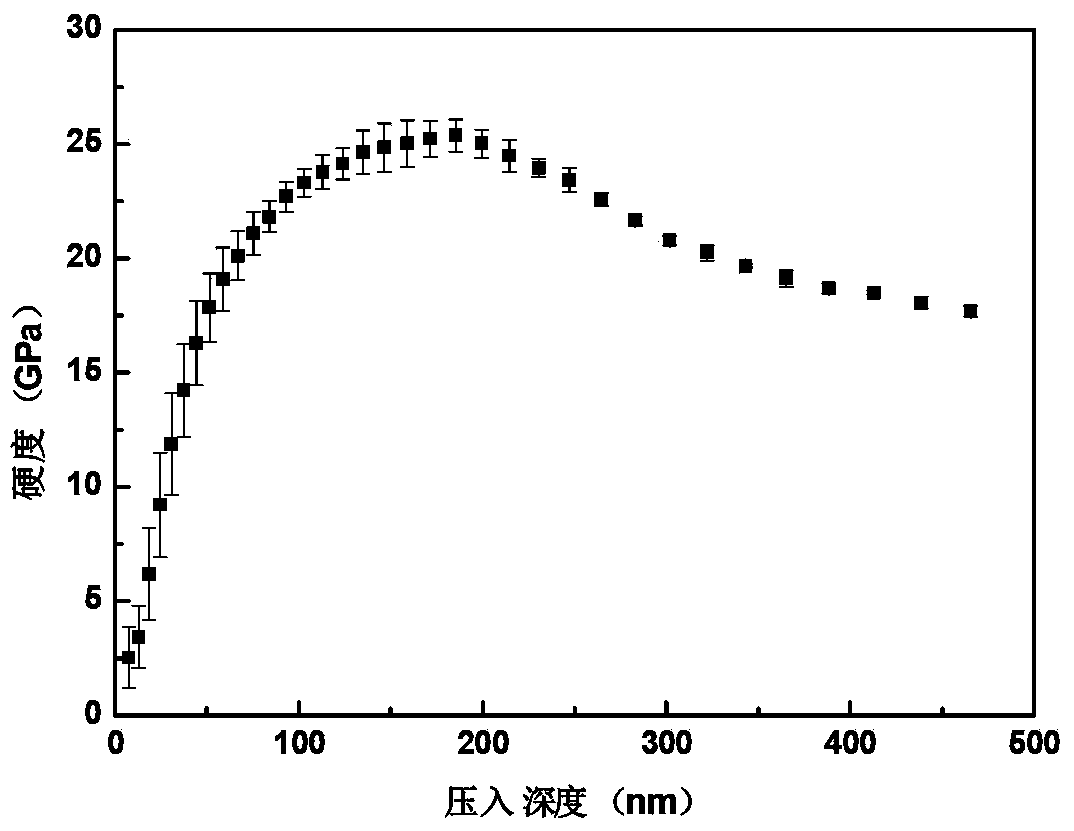

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com