Method for improving metalized surface performance of ceramic workpiece

A technology for metallized surface and workpiece surface, applied in the field of functional ceramic materials, can solve problems such as affecting product quality, easy oxidation, poor adhesion of film layers, etc., to achieve consistency and large-scale production convenience, chemical ratio is not easy to imbalance, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

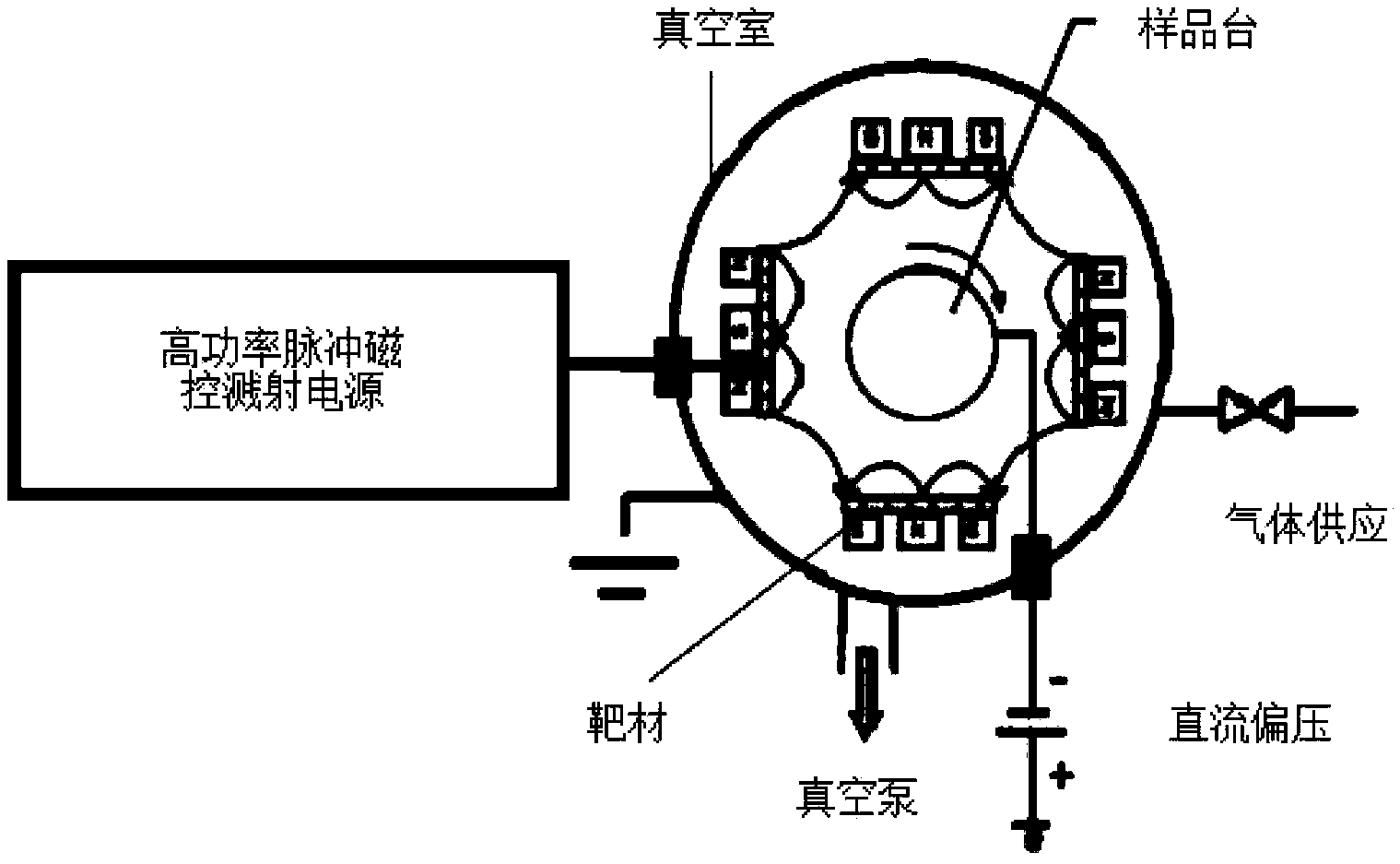

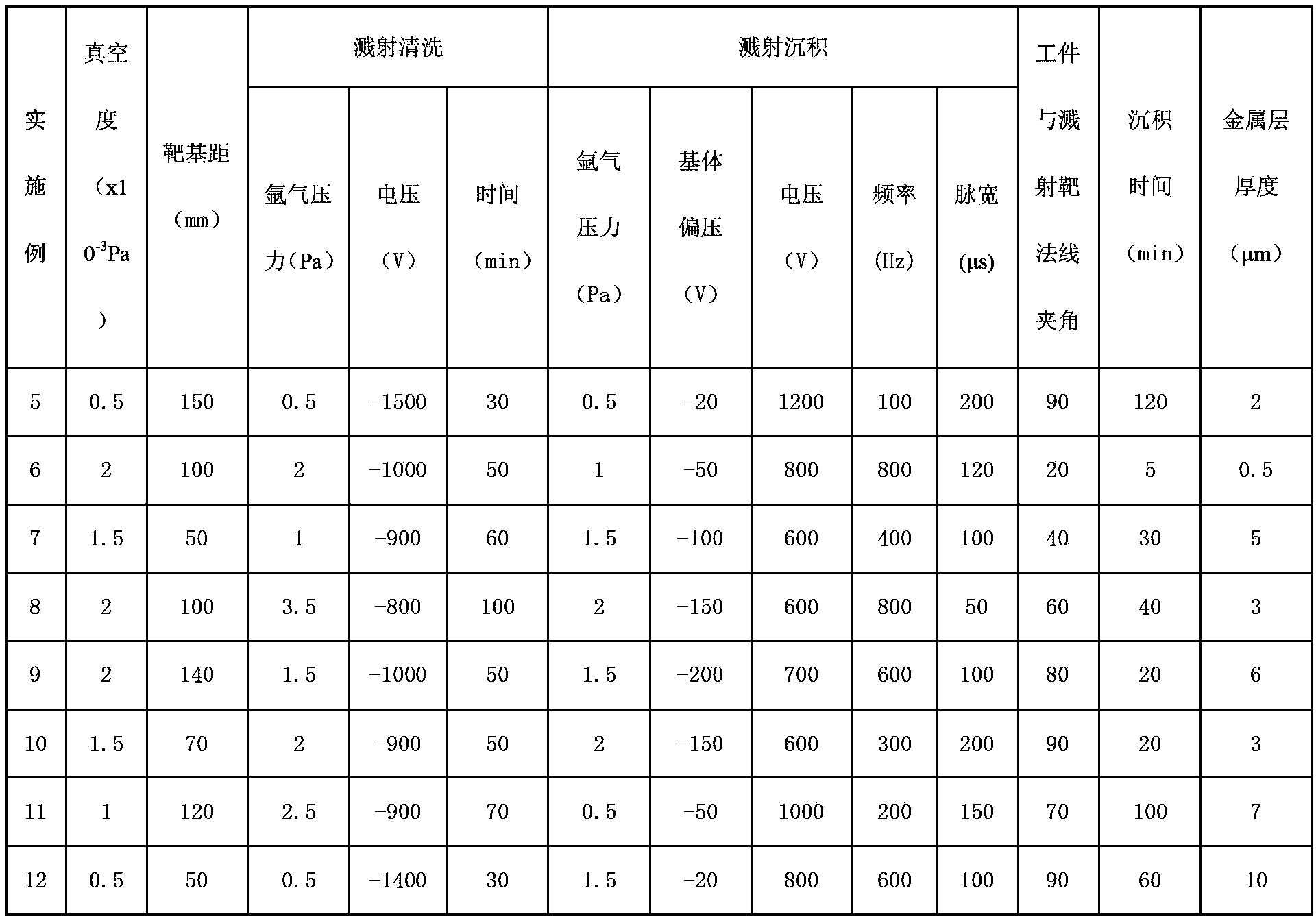

[0031] A specific embodiment of the present invention is as follows: the equipment is shown as figure 1 As shown, it is mainly composed of three parts: high-power pulse magnetron sputtering power supply system, gas flow and pressure control system, and vacuum system. The ceramic workpiece that needs surface metallization is fixed on the sample stage. The specific steps are:

[0032] A. Ultrasound the alumina ceramic workpiece in acetone and absolute ethanol for 10 minutes and take it out, then dry it for use;

[0033] B. Immerse the dried alumina ceramic workpiece in molten sodium hydroxide for 10 minutes, and adjust the temperature at a constant temperature of 500 degrees Celsius; ultrasonically clean and dry the etched alumina ceramic workpiece in absolute ethanol;

[0034] C. Fix the alumina ceramic workpiece on the stainless steel substrate and put it into the vacuum chamber of the high-power pulse magnetron sputtering equipment, and the vacuum chamber is evacuated to 2×10...

Embodiment 2

[0040] A. Ultrasound the silicon dioxide ceramic workpiece for 40 minutes in acetone and absolute ethanol respectively, take it out, and then dry it for use;

[0041] B. Immerse the dried silicon dioxide ceramic workpiece in 30wt% sodium hydroxide for 40 minutes, adjust the constant temperature at 80 degrees Celsius; ultrasonically clean and dry the etched alumina ceramic workpiece in absolute ethanol;

[0042] C. Fix the silicon dioxide ceramic workpiece on the stainless steel substrate and put it into the vacuum chamber of the high-power pulse magnetron sputtering equipment, and the vacuum chamber is evacuated to 0.5×10 -3 Pa; adjust the distance between copper target and ceramic workpiece to 100mm;

[0043] D. Introduce argon gas into the vacuum chamber to a pressure of 2.8Pa, apply a DC voltage of -1450V, glow discharge to form a plasma, and perform sputter cleaning on the silicon dioxide ceramic workpiece for 40 minutes, then turn off the argon gas and DC power supply;

...

Embodiment 3

[0047] A. Put the fluorphlogopite ceramic workpiece in acetone and absolute ethanol respectively, ultrasonically take it out for 15 minutes, and then dry it for use;

[0048] B. Immerse the dried fluorphlogopite ceramic workpiece in 0.1g / L tin chloride solution for 40 minutes, and adjust the temperature at a constant temperature of 50 degrees Celsius; ultrasonically clean and dry the etched fluorphlogopite ceramic workpiece in absolute ethanol Dry;

[0049] C. Fix the fluorine phlogopite ceramic workpiece on the stainless steel substrate and put it into the vacuum chamber of the high-power pulse magnetron sputtering equipment, and the vacuum chamber is evacuated to 1.5×10 -3 Pa; adjust the distance between the titanium target and the ceramic workpiece to 75mm;

[0050] D. Introduce argon gas into the vacuum chamber to a pressure of 3.0Pa, apply a DC voltage of -1450V, glow discharge to form plasma, and sputter and clean the fluorphlogopite ceramic workpiece for 40 minutes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com