Nanometer silver-nanocrystalline cellulose compound, preparation method of nanometer silver-nanocrystalline cellulose compound, and application of nanometer silver-nanocrystalline cellulose compound

A nano-microcrystalline and cellulose technology, applied in the field of nano-materials, can solve the problems of large nano-silver particles, uneven dispersion, long reaction time, etc., and achieve the effect of uniform particle size, simple raw materials, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of nanometer silver-nanometer microcrystalline cellulose compound, its preparation method comprises the following steps:

[0041] (1) Under the condition of magnetic stirring at 30 rpm, add 10 g of nanocrystalline cellulose aqueous solution with a mass fraction of 6% to 352 ml of AgNO with a concentration of 0.001 mol / L 3 solution, stirred for 0.5 hours;

[0042](2) Stir the mixed solution in step (1) in an ultrasonic container under the reaction conditions of a stirring rate of 50 rpm and a power of 100 watts for 20 minutes, and centrifuge the reaction solution at 10,000 r / min for 15 minutes after the reaction. Take the precipitate, wash it successively with absolute ethanol and distilled water, and obtain the product nano-silver-nano-microcrystalline cellulose composite.

[0043] (3) The obtained product was dried in vacuum at 60° C. for 3 h, and the dried product nanosilver-nanocrystalline cellulose composite was designated as Ag / NCC-1.

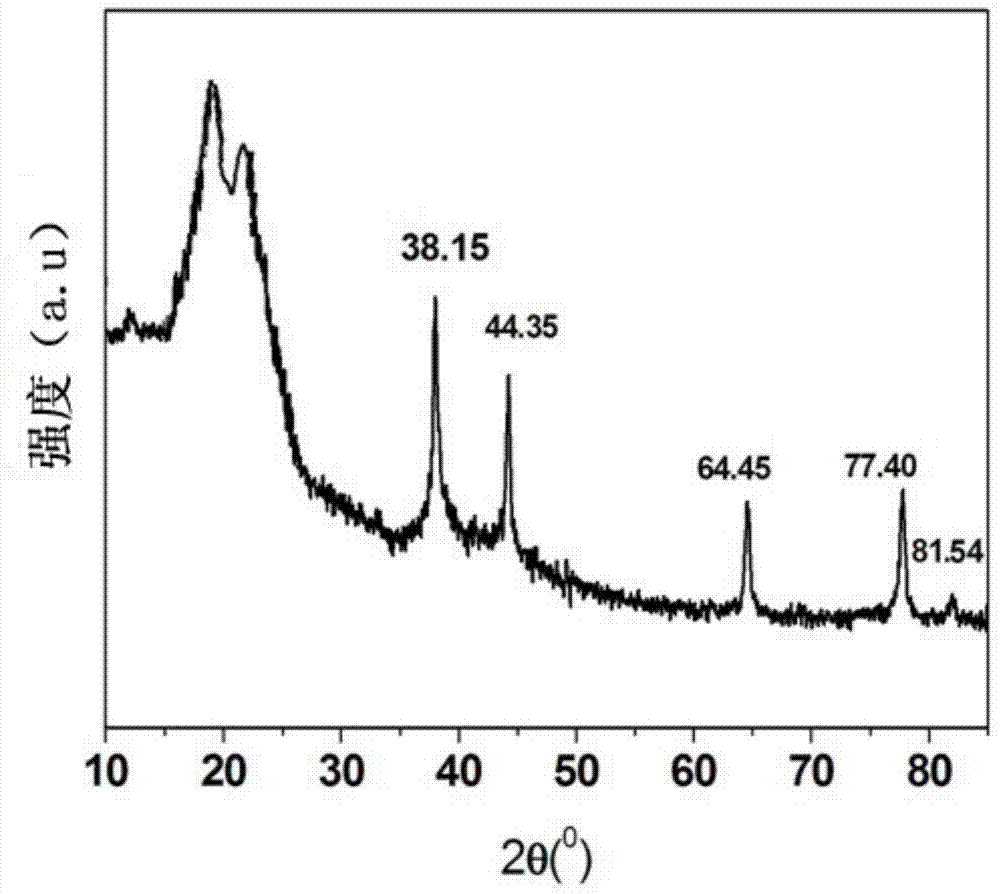

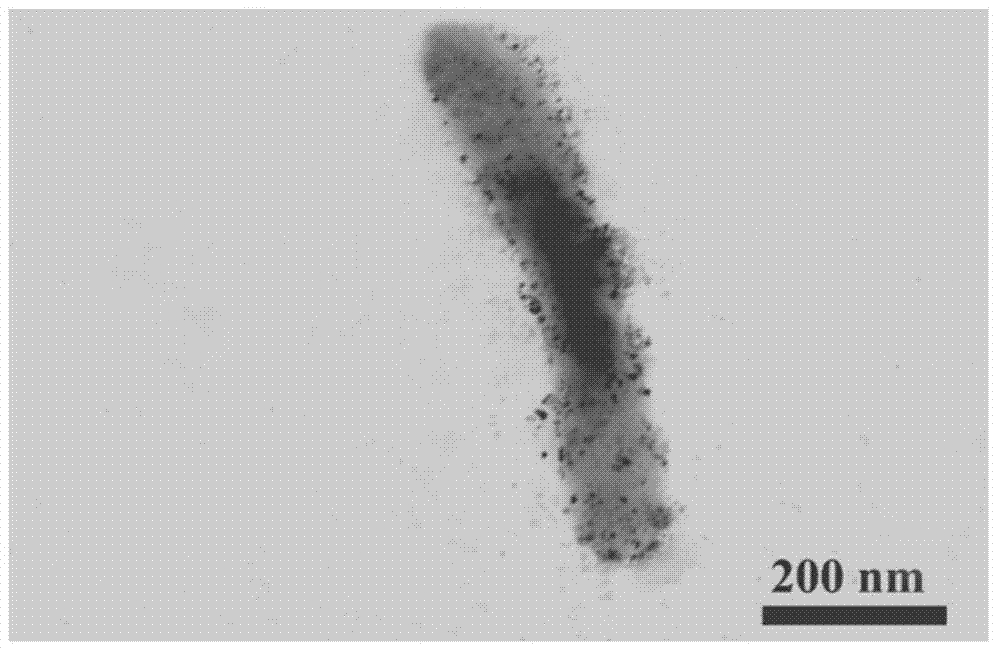

[0044] Carry out X-...

Embodiment 2

[0047] A kind of nanometer silver-nanometer microcrystalline cellulose compound, its preparation method comprises the following steps:

[0048] (1) Under the condition of magnetic stirring at 50 rpm, add 15 g of nanocrystalline cellulose aqueous solution with a mass fraction of 10% to 9 ml of Ag (CH 3 COO) 2 solution, stirred for 0.6 hours;

[0049] (2) Stir the mixed solution in step (1) in an ultrasonic container under the reaction conditions of a stirring rate of 70 rpm and a power of 600 watts for 40 minutes, and centrifuge the reaction solution at 10,000 r / min for 15 minutes after the reaction. Take the precipitate, wash it successively with absolute ethanol and distilled water, and obtain the product nano-silver-nano-microcrystalline cellulose composite.

[0050] (3) The obtained product was dried in vacuum at 60° C. for 3 h, and the dried product nanosilver-nanocrystalline cellulose composite was designated as Ag / NCC-2.

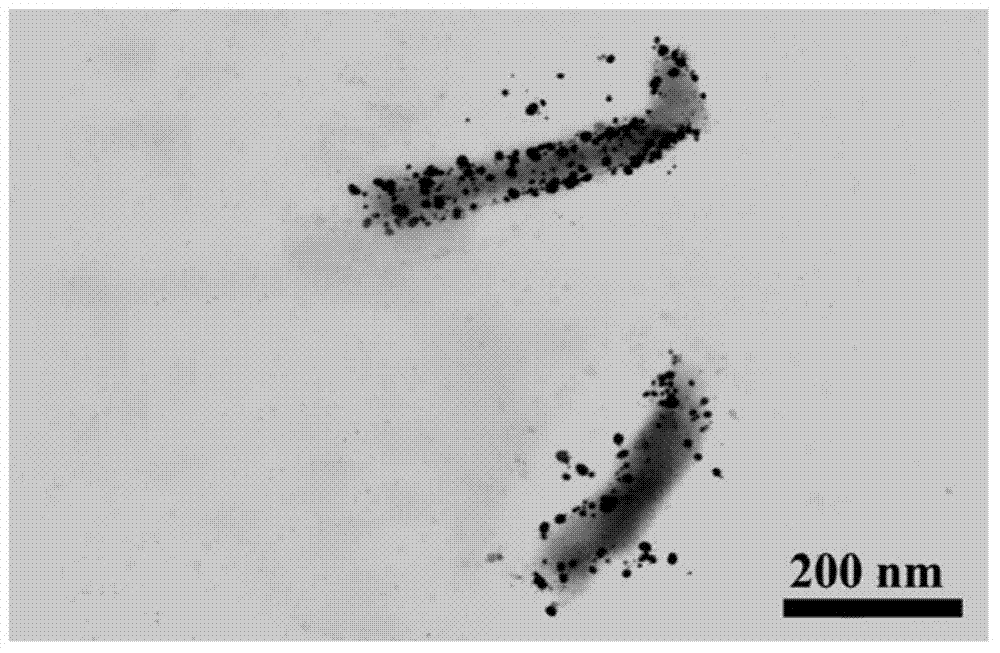

[0051] The obtained nano-silver-nano-microcry...

Embodiment 3

[0053] A kind of nanometer silver-nanometer microcrystalline cellulose compound, its preparation method comprises the following steps:

[0054] (1) Under the condition of magnetic stirring at 100 rpm, add 12 g of nanocrystalline cellulose aqueous solution with a mass fraction of 15% to 142 ml of AgF solution with a concentration of 0.01 mol / L, and stir for 0.6 hours;

[0055] (2) Stir the mixed solution in step (1) in an ultrasonic container under the reaction conditions of a stirring rate of 100 rpm and a power of 1000 watts for 60 minutes. After the reaction, centrifuge the reaction solution at 10000 r / min for 15 minutes, and take Precipitation, washing with absolute ethanol and distilled water in sequence to obtain the product nano-silver-nano-microcrystalline cellulose composite.

[0056] (3) The obtained product was dried in vacuum at 60° C. for 3 h, and the dried product nanosilver-nanocrystalline cellulose composite was designated as Ag / NCC-3.

[0057] The obtained nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com