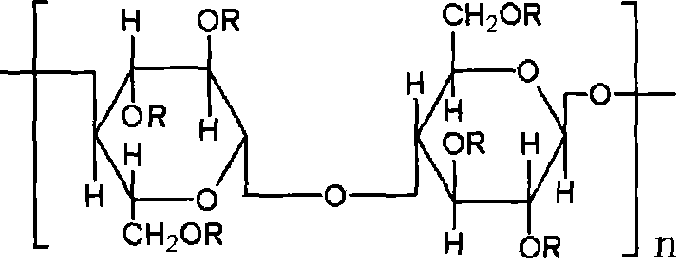

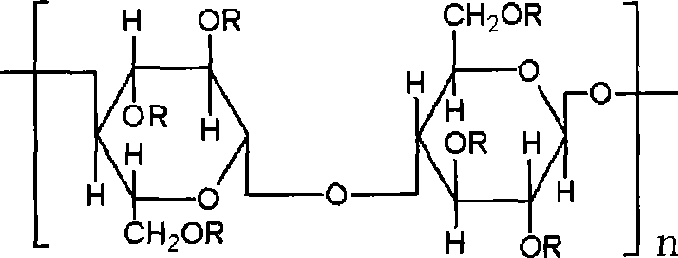

Polysubstituted radical cellulose composite ether and its preparing method

A technology of base cellulose and compound ether, which is applied in the field of multi-substituted cellulose compound ether and its preparation, can solve the problems of poor solution stability, high gel temperature of cellulose compound ether, low water retention performance, etc. The effect of low production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Add a certain combination of mixed solvent containing 520KG alkali into a 10 cubic meter stainless steel reactor, stir and cool down to 10-30°C, keep stirring.

[0032] 2. Cool down to below room temperature, add 500KG of refined cotton, vacuumize for 20-30 minutes, keep the temperature and stir for 1-3 hours.

[0033] 3. Add propylene oxide, ethylene oxide and methyl chloride, heat up to 50-70°C, react for 1-2 hours, react at 70-85°C for 1-2 hours, and react at above 85°C for 1-1.5 hours. Observe the reading of the pressure gauge, keep the pressure at 0.3-0.5 MPa for 1 hour, and raise the temperature to maintain the pressure when necessary.

[0034] 4. Start to recover the solvent, and at the same time add hot water above 85°C (a total of 6000kg), and recover until the temperature in the kettle reaches above 95°C and maintain it for 30 minutes.

[0035] 5. Cool to 60-80°C, then add hydrochloric acid to adjust the pH to 4.0-8.0, stir for 20-40 minutes, centrifuge an...

Embodiment 2

[0045] 1. Add 200KG of refined cotton to a 2.5 cubic meter stainless steel reactor, add 650KG of dimethyl ether after vacuuming, stir and cool down to 10-30°C.

[0046] 2. Spray 160KG of 50% sodium hydroxide solution, and keep stirring at 10-15°C for 1-3 hours.

[0047] 3. Add 120 KG of methyl chloride, 100 KG of propylene oxide, and 80 KG of ethylene oxide, raise the temperature to 30-60 °C for 1-3 hours, and react at 60-85 °C for 1-3 hours.

[0048] 4. Start to recover the solvent, and then add hot water above 85°C (800kg in total) and mix for 30 minutes.

[0049] 5. Cool to 60-80°C, then add hydrochloric acid to adjust the pH to 4.0-8.0, stir for 20-40 minutes, centrifuge and dry.

[0050]6. After crushing, the hydroxyethyl content is 2.1%, the representative methoxy content is 18.6%, and the hydroxypropyl content is 7.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com