Different-shape polyester fiber and wood pulp cellulose compound spunlacing wet tissue cloth and preparation method for same

A technology of polyester fiber and wood pulp fiber, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of unsatisfactory thickness requirements and restrictions, and achieve the effect of good water absorption, no binder, and uniform network formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, 25.0wt% of polyester fiber, 25wt% of hollow polyester fiber and 50wt% of wood pulp fiber are used to prepare by the following spunlace method;

[0024] (1) Raw material preparation: adopt weighing machine to weigh above-mentioned proportioning raw material;

[0025] (2) Preliminary opening and mixing of raw materials: put the raw materials into the cotton blending window opener for preliminary opening and mixing;

[0026] (3) Mixing: use a cotton mixer to further evenly mix the raw materials after the initial opening;

[0027] (4) Fine opening: Use a cotton opener to finely open the evenly mixed raw materials;

[0028] (5) Feeding adjustment: feed the finely opened and loosened raw materials to the carding machine through the finishing cotton box and the air pressure cotton box;

[0029] (1) Carding into a web: the carding machine combs the finely opened raw materials into a fiber web. The range of technological parameters of the carding machine: main...

Embodiment 2

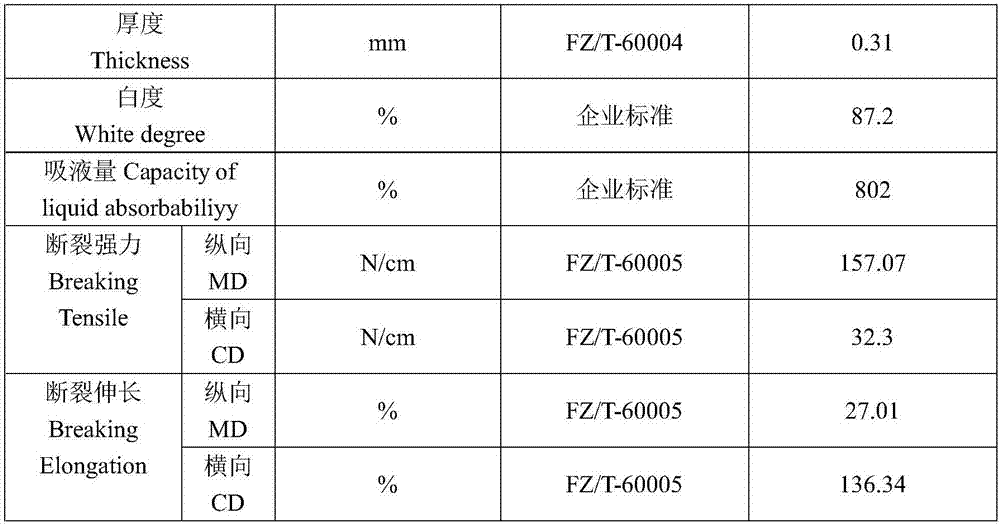

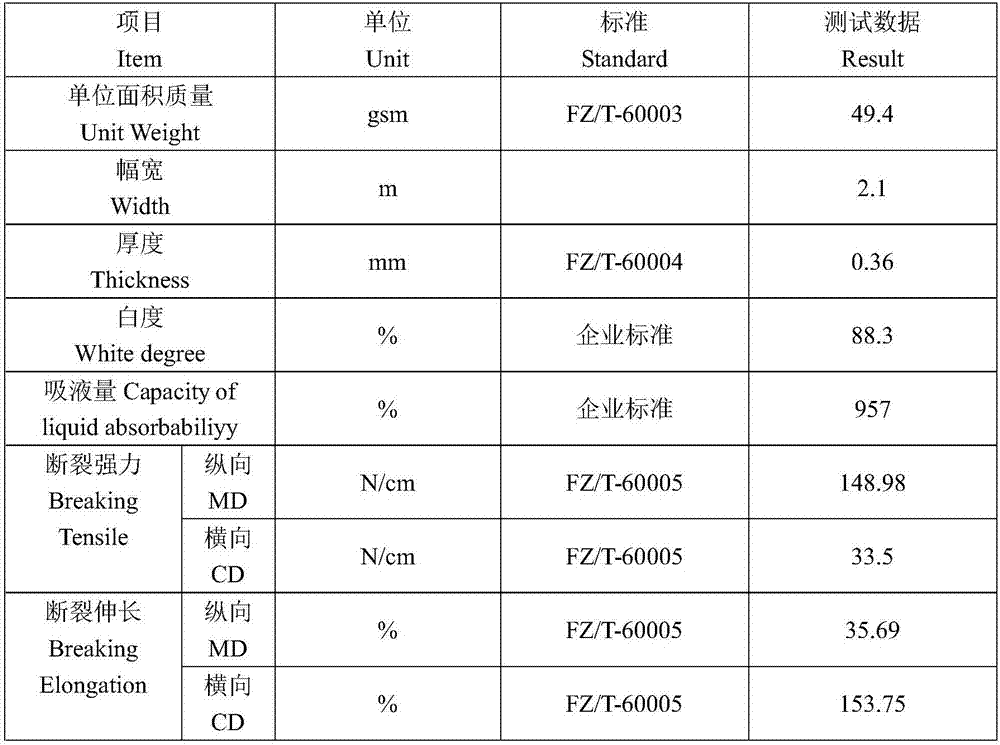

[0039] The preparation method of this example is the same as that of Example 1, except that the raw material hollow polyester fiber is 50wt% and wood pulp fiber is 50wt%. The performance parameter test report of the product under this ratio is as follows:

[0040]

[0041] In the present invention, the wood pulp fiber has good hygroscopicity, and when spunlace, the wood pulp fiber absorbs water and expands, so that the area facing the water becomes larger, the efficiency of the water needle driving the fiber movement is improved, and the fiber entanglement effect is good;

[0042] Polyester fiber has high modulus, good elasticity and ductility, and good wear resistance, so the three-layer composite material has good wear resistance, and the three-layer structure reduces the loss rate of wood pulp fibers;

[0043] In addition, the invention innovatively adopts hollow polyester fiber, which has many curls, increased thickness, and good water absorption, so that the wood pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com