Cement-based abrasion-resistant material for II type concrete floor

A wear-resistant material, cement-based technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as high price, unstable output and quality, and unsatisfactory market supply, and achieve cost Low cost, low cost and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A type II cement-based wear-resistant material for concrete floors, which is prepared from ordinary Portland cement, emery, steel slag, redispersible latex powder, water reducing agent, silica fume, cellulose compounds and fly ash; The parts by weight of each substance are: 45 parts of ordinary Portland cement, 35 parts of emery, 12 parts of steel slag, 1.5 parts of redispersible polymer powder, 0.25 parts of polycarboxylate water reducing agent, 8 parts of silica fume, cellulose compounds 0.1 part, 10 parts fly ash.

[0016] The above substances are mixed according to the formula ratio and evenly stirred to obtain the cement-based wear-resistant material for type II concrete floor.

Embodiment 2

[0018] A type II cement-based wear-resistant material for concrete floors, which is composed of ordinary Portland cement, emery, steel slag, redispersible latex powder, water reducing agent, silica fume, cellulose compounds and fly ash. The parts by weight are: 42 parts of ordinary Portland cement, 30 parts of emery, 14 parts of steel slag, 0.5 part of redispersible latex powder, 0.2 part of polycarboxylate water reducing agent, 5 parts of silica fume, 0.08 part of cellulose compound, 13 parts of fly ash.

[0019] The above substances are mixed according to the formula ratio and evenly stirred to obtain the cement-based wear-resistant material for type II concrete floor.

Embodiment 3

[0021] A type II cement-based wear-resistant material for concrete floors, which is composed of ordinary Portland cement, emery, steel slag, redispersible latex powder, water reducing agent, silica fume, cellulose compounds and fly ash. The parts by weight are: 50 parts of ordinary Portland cement, 40 parts of emery, 10 parts of steel slag, 1.5 parts of redispersible latex powder, 0.35 parts of polycarboxylate water reducing agent, 10 parts of silica fume, 0.12 parts of cellulose compounds, 8 parts of fly ash.

[0022] The above substances are mixed according to the formula ratio and evenly stirred to obtain the cement-based wear-resistant material for type II concrete floor.

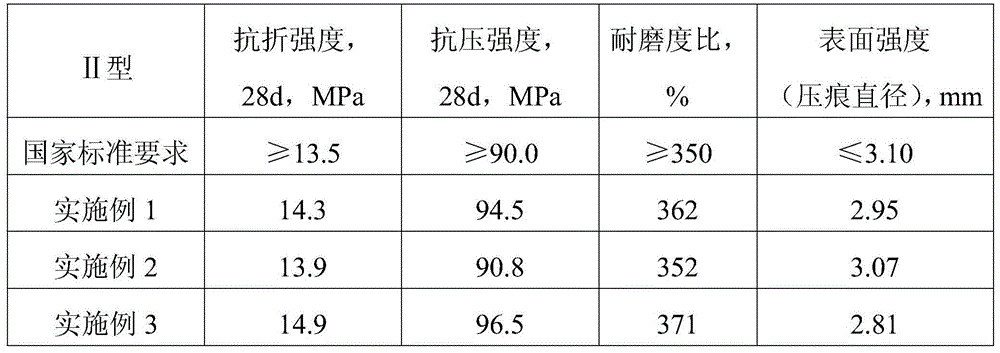

[0023] Table 1 shows the properties of a type II cement-based wear-resistant material for concrete floors of Examples 1, 2 and 3. From the data in the table, it can be seen that the performance of a type II cement-based wear-resistant material for concrete floors in Examples 1, 2 and 3 meets the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com