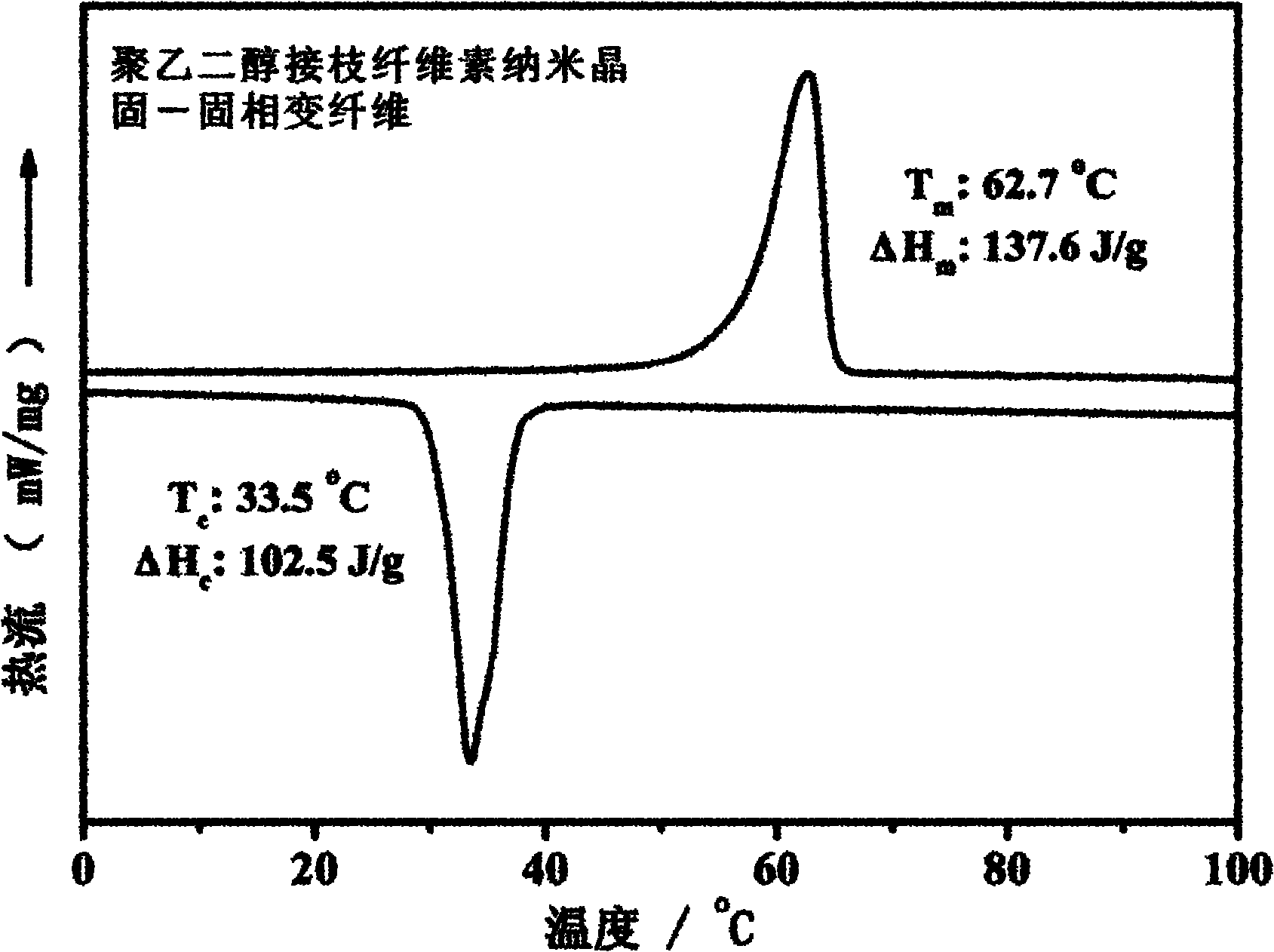

Method for preparing biodegradable solid-solid phase transition nano fibers or fiber membranes

A nanofiber, fiber membrane technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of strict spinning conditions, and achieve the effect of strong application potential, strong operability, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First mix the oxalic acid and CNC aqueous dispersion (16.1mg / mL) evenly, then add DMAP, wherein the reaction ratio of CNC, oxalic acid and DMAP is 1:1.2:0.04; then DCC ethanol solution (15mg / mL) Slowly add it dropwise to the above dispersion liquid, the ratio of CNC and DCC is 1:0.3~0.6, and react with magnetic stirring at room temperature for 6 hours; the product is repeatedly washed and centrifuged with deionized water and absolute ethanol, and then prepared into CNC - Aqueous dispersion of COOH.

[0031] Add PEG (the average molecular weight is 6000) and DMAP to the above-mentioned dispersion solution in turn, wherein the reaction ratio of CNC-COOH, PEG and DMAP is 1:3.5:0.05; the ethanol solution of DCC (15mg / mL ), the ratio of CNC-COOH to DCC was 1:0.3-0.6, and the reaction was continued at 70°C for 12 hours; the product was repeatedly washed with deionized water and anhydrous ether, centrifuged, and vacuum-dried to obtain PEG-g-CNC.

[0032] Then the above-mentio...

Embodiment 2

[0034] After mixing the aqueous dispersion (18mg / mL) of succinic acid and CNC evenly, add DBTL, wherein the reaction ratio of CNC, succinic acid and DBTL is 1:1:0.2; then the ethanol solution of DCC (15mg / mL) was slowly added dropwise to the above dispersion liquid, the ratio of CNC and DCC was 1:0.3~0.6, and the reaction was carried out under magnetic stirring at room temperature for 6 hours; the product was repeatedly washed and centrifuged with deionized water and absolute ethanol, and then Prepared as CNC-COOH water dispersion.

[0035] Then PEG (average molecular weight is 6000) and DBTL are sequentially added to the dispersion liquid prepared above, wherein the reaction ratio of CNC-COOH, PEG and DBTL is 1:4:0.2; the ethanol solution of DCC (15 mg / mL), the ratio of CNC-COOH and DCC was 1:0.3-0.6, and the reaction was continued at 80°C for 10 h; the product was repeatedly washed with deionized water and anhydrous ether, centrifuged, and vacuum-dried to obtain PEG-g-CNC....

Embodiment 3

[0038] First mix the oxalic acid and CNC aqueous dispersion (17mg / mL) evenly, then add DMAP, wherein the reaction ratio of CNC, oxalic acid and DMAP is 1:1:0.04; then DCC ethanol solution (15mg / mL) slowly Add dropwise to the above dispersion liquid, the ratio of CNC and DCC is 1:0.3~0.6, and react with magnetic stirring at room temperature for 6 hours; the product is repeatedly washed and centrifuged with deionized water and absolute ethanol, and then prepared into CNC- Aqueous dispersion of COOH.

[0039] Then PEG (average molecular weight is 4000) and DMAP are added in the dispersion liquid of above-mentioned preparation successively, wherein the reaction proportion of CNC-COOH, PEG and DMAP is 1: 3.5: 0.06; The ethanol solution of DCC (15mg / mL), the ratio of CNC-COOH and DCC was 1:0.3-0.6, and the reaction was continued at 60°C for 10 h; the product was repeatedly washed with deionized water and anhydrous ether, centrifuged, and vacuum-dried to obtain PEG-g-CNC.

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com