Chiral nematic cellulose nanocrystal-glycerol composite film and preparation method and application thereof

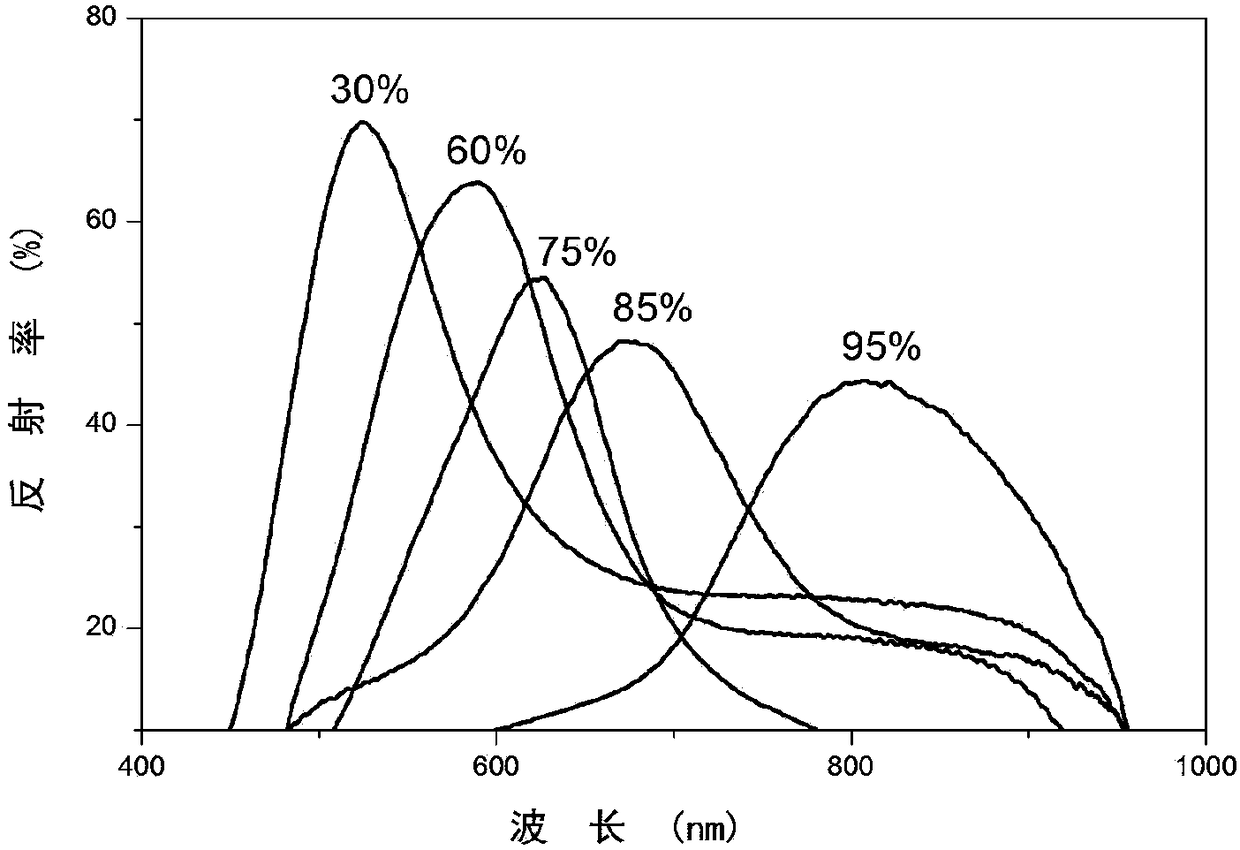

A nanocrystal and chiral nematic technology, which is applied in the field of chiral nematic cellulose nanocrystal-glycerol composite film and its preparation, can solve the problem that the detection effect of humidity sensitive indicator materials is not intuitive, and achieve a good humidity detection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of a chiral nematic cellulose nanocrystal-glycerol composite film, comprising the following steps:

[0026] Mixing fibers and sulfuric acid for hydrolysis reaction to obtain cellulose nanocrystal suspension;

[0027] The cellulose nanocrystal suspension is washed and concentrated in sequence to obtain a chiral nematic cellulose nanocrystal suspension with a mass concentration of 1.5-5.5%;

[0028] The chiral nematic cellulose nano crystal suspension is mixed with glycerol aqueous solution to form a film to obtain a chiral nematic cellulose nano crystal-glycerol composite film.

[0029] The invention mixes fiber and sulfuric acid to carry out hydrolysis reaction to obtain cellulose nano crystal suspension. In the present invention, the fiber preferably includes pulp fiber, bamboo fiber or microcrystalline cellulose; the pulp fiber preferably includes pulp cotton fiber or kraft bleached coniferous pulp, more preferably pulp cot...

Embodiment 1

[0045] Mix 15g of pulp fiber with 150mL of sulfuric acid with a mass concentration of 70%. Under 700rpm, carry out the hydrolysis reaction in a water bath at 25°C for 1.5h, mix the obtained hydrolyzed material with 1500mL of distilled water, and let it settle for 20h to obtain the supernatant and The lower turbid liquid; the supernatant is poured out, the remaining lower turbid liquid is cleaned with distilled water, and then the obtained material is centrifuged 3 times to obtain a centrifuged material with a pH value of 2.0, wherein the upper layer obtained after each centrifugation Pour it away at night, wash the resulting lower layer of turbid liquid with distilled water, and then perform the next centrifugation, the centrifugal speed is 3000rpm, and the time of single centrifugation is 6min; the obtained centrifuged material is dialyzed for 7 days with a molecular weight cut-off of 8000 to obtain pH The dialysis material with a value of 6.0; the obtained dialysis material i...

Embodiment 2

[0052] Mix 20g of pulp fiber with 250mL of sulfuric acid with a mass concentration of 75%. Under 900rpm, carry out the hydrolysis reaction in a 75°C water bath for 3h, mix the obtained hydrolyzed material with 2500mL of distilled water, and let it settle for 30h to obtain the supernatant and the lower layer. Turbid liquid; pour out the supernatant, wash the remaining lower turbid liquid with distilled water, then centrifuge the obtained material 3 times to obtain a centrifuged material with a pH value of 2.0, wherein the supernatant obtained after each centrifugation Pour it away, wash the resulting lower layer of turbid liquid with distilled water, and then perform the next centrifugation, the centrifugal speed is 5000rpm, and the time of single centrifugation is 7min; the obtained centrifuged material is dialyzed for 5 days with a molecular weight cut-off of 10000 to obtain the pH value The dialysis material is 7.0; the obtained dialysis material is concentrated to a mass con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com