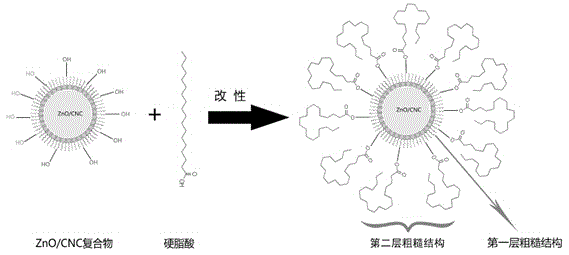

Preparation method of zinc oxide and cellulose nanocrystal composite super-hydrophobic coating

A technology of super-hydrophobic coating and nanocrystals, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of poor water resistance and mechanical properties, and achieve easy operation and simple preparation process , enhance the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] A preparation method for a zinc oxide / cellulose nanocrystal composite superhydrophobic coating, specifically comprising the steps of:

[0013] 1) Prepare nano-zinc oxide (ZnO) by water bath method: take 80-150ml of zinc nitrate hexahydrate and hexamethylenetetramine solutions of equal concentration (0.005-0.1mol / L) respectively, mix them and use a heat collector to keep the temperature Heat the magnetic stirrer at a temperature of 85-95 ° C for 1-4 hours, take it out and let it stand for aging for 1-2 days, pour out the supernatant, and perform centrifugal washing to remove residual ions and ammonium salts in the solution, centrifuge The speed is 6000rpm, the time is 5min, and the number of times is 3-4 times, that is, nano-zinc oxide is obtained;

[0014] 2) Preparation of cellulose nanocrystal solution:

[0015] ① Acid treatment: treat microcrystalline cellulose (MCC) with sulfuric acid at a concentration of 56%, and the mass ratio is MCC:H 2 SO 4 =1: (9.15-10.35),...

Embodiment 1

[0028] A preparation method of zinc oxide / cellulose nanocrystal composite superhydrophobic coating, comprising the steps:

[0029] 1) Preparation of nano-zinc oxide by water bath method: take 90ml of the mass fraction as 0.05mol / L

[0030] The solution of zinc nitrate hexahydrate and hexamethylenetetramine was mixed and then stirred with a collector-type constant temperature heating magnetic stirrer at a temperature of 90°C for 2 hours. After taking it out, it was left to age for 1 day, and the supernatant was poured out. And carry out centrifugal washing to remove residual ions and ammonium salts in the solution, the centrifugal speed is 6000rpm, the time is 5min, and the number of times is 4 times to obtain nano-zinc oxide;

[0031] 2) Preparation of cellulose nanocrystals by sulfuric acid hydrolysis: first, microcrystalline cellulose (MCC) was treated with sulfuric acid at a concentration of 56%, and the mass ratio was MCC:H 2 SO 4 =1: (9.15-10.35), the acid hydrolysis te...

Embodiment 2

[0039] The preparation method of special morphology zinc oxide / cellulose nanocrystal composite superhydrophobic coating comprises the steps:

[0040] 1) Prepare nano-zinc oxide by water bath method: take 100ml mass fraction as 0.1mol / L

[0041] The solution of zinc nitrate hexahydrate and hexamethylenetetramine was mixed and then stirred with a collector-type constant temperature heating magnetic stirrer at a temperature of 95°C for 2 hours. After taking it out, it was left to age for 1 day, and the supernatant was poured out. And carry out centrifugal washing to remove residual ions and ammonium salts in the solution, the centrifugal speed is 6000rpm, the time is 5min, and the number of times is 4 times to obtain nano-zinc oxide;

[0042]2) Preparation of cellulose nanocrystals by sulfuric acid hydrolysis: first, microcrystalline cellulose (MCC) was treated with sulfuric acid at a concentration of 56%, and the mass ratio was MCC:H 2 SO 4 =1:10, the acid hydrolysis temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com