Preparation method of composite material with fiber surface coated with cellulose nano crystals and used for multi-scale enhancement

A technology for reinforcing composite materials and fiber surfaces, applied in the field of materials, can solve the problems of high cost, low preparation efficiency, poor macroscopic mechanical properties of fiber composite materials, etc., achieve low price, increase interlayer shear strength and interface bond strength , easy to disperse and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

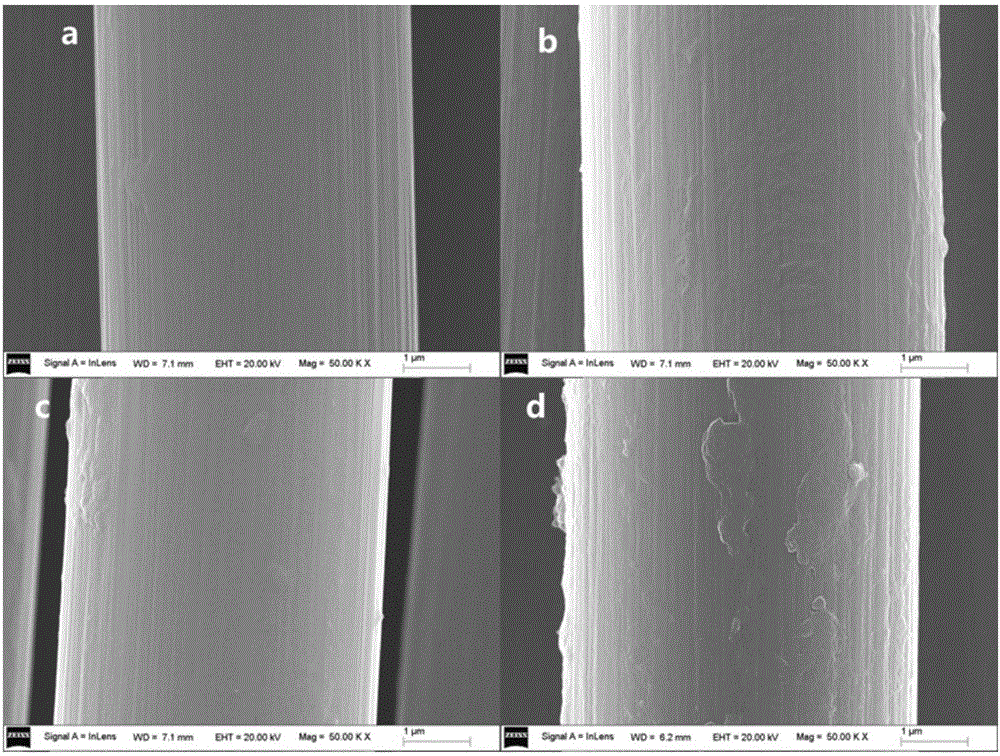

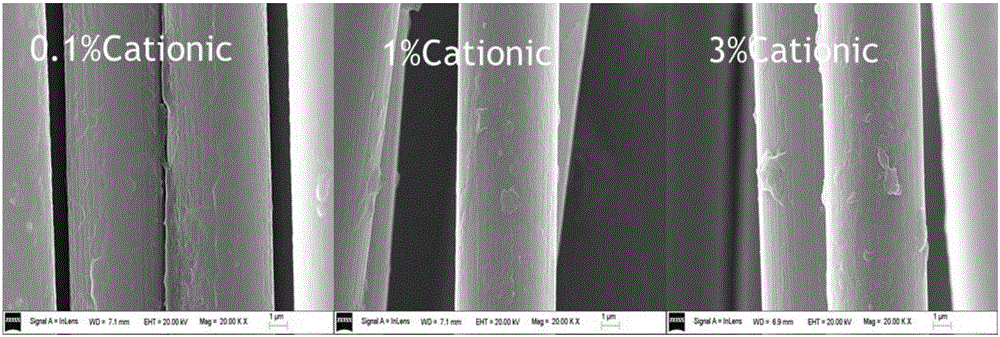

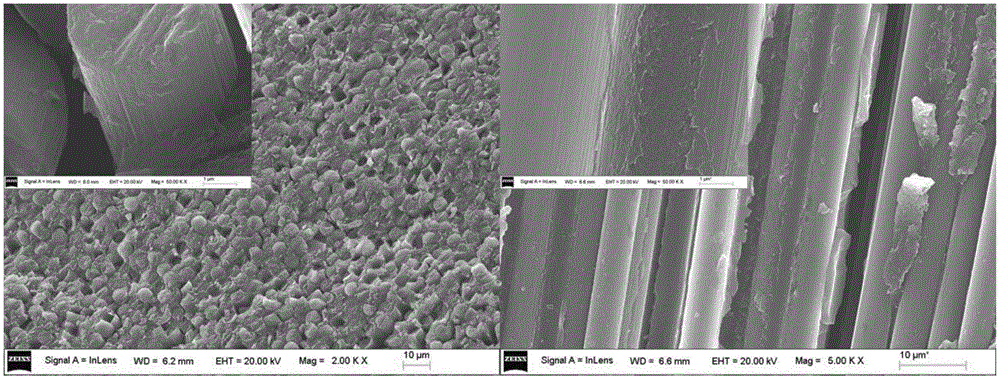

Embodiment 1

[0019] Put 10nm cationic cellulose nanocrystals, deionized water, and sizing agent into the device at a mass ratio of 0.1:97:3 for mechanical stirring, stirring at a speed of 500r / min for 10min, and ultrasonication for 10min to obtain the dispersed particles. The above sizing solution: Wind the unsized T800 carbon fiber on the tractor, apply a certain tension, and carry out the sizing treatment. The soaking time is 30s, and the water is dried online at 250°C. The fibers coated with cellulose nanocrystals were prepared into unidirectional composite material splines, and cured according to the selection of epoxy resin amine curing agent system at 90°C / 1h+130°C / 3h+180°C / 2h , to obtain carbon fiber composites coated with cellulose nanocrystals on the fiber surface, and conduct interlaminar shear tests and micro-debonding tests. The test results show that the interlaminar shear strength is 2.4% higher than that of Comparative Example 1; the IFSS result obtained from the micro-debon...

Embodiment 2

[0021] Put 10nm cationic cellulose nanocrystals, deionized water, and sizing agent into the device at a mass ratio of 1:97:3 for mechanical stirring, stir at a speed of 500r / min for 10min, and ultrasonicate for 5min to obtain the dispersed particles. The above sizing solution: Wind the unsized T800 carbon fiber on the tractor, apply a certain tension to carry out the sizing treatment, the soaking time is 60s, and dry online at 200°C to remove water. The fibers coated with cellulose nanocrystals were prepared into unidirectional composite material splines, and cured according to the selection of epoxy resin amine curing agent system at 90°C / 1h+130°C / 3h+180°C / 2h , to obtain multi-scale reinforced composite materials coated with cellulose nanocrystals on the surface of fibers, and make specimens for interlaminar shear test and micro-debonding test. The test results show that the interlaminar shear strength is 6.3% higher than that of Comparative Example 1; the IFSS result obtaine...

Embodiment 3

[0023] Put 10nm cationic cellulose nanocrystals, deionized water, and sizing agent into the device with a mass ratio of 3:97:3 for mechanical stirring, stir at a speed of 500r / min for 10min, and ultrasonicate for 5min to obtain the dispersed particles. The above sizing solution: wind the unsized carbon fiber on the tractor, apply a certain tension to carry out the sizing treatment, the soaking time is 60s, and dry online at 200°C to remove water. The fibers coated with cellulose nanocrystals were prepared into unidirectional composite material splines, and cured according to the selection of epoxy resin amine curing agent system at 90°C / 1h+130°C / 3h+180°C / 2h , to obtain multi-scale reinforced composite materials coated with cellulose nanocrystals on the surface of fibers, and make specimens for interlaminar shear test and micro-debonding test. The test results show that the interlaminar shear strength is 0.2% higher than that of Comparative Example 1; the IFSS result obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com