Method for preparing cellulose nanocrystal reinforced polyhydroxybutyrate-hydroxyvalerate (PHBV) nanofiber

A nanofiber and nanocrystal technology is applied in the field of preparation of PHBV nanofibers, which can solve the problems that the performance of PHBV nanofibers cannot be well improved, and achieve the effects of suitable hydrophilic properties, high thermal degradation temperature and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

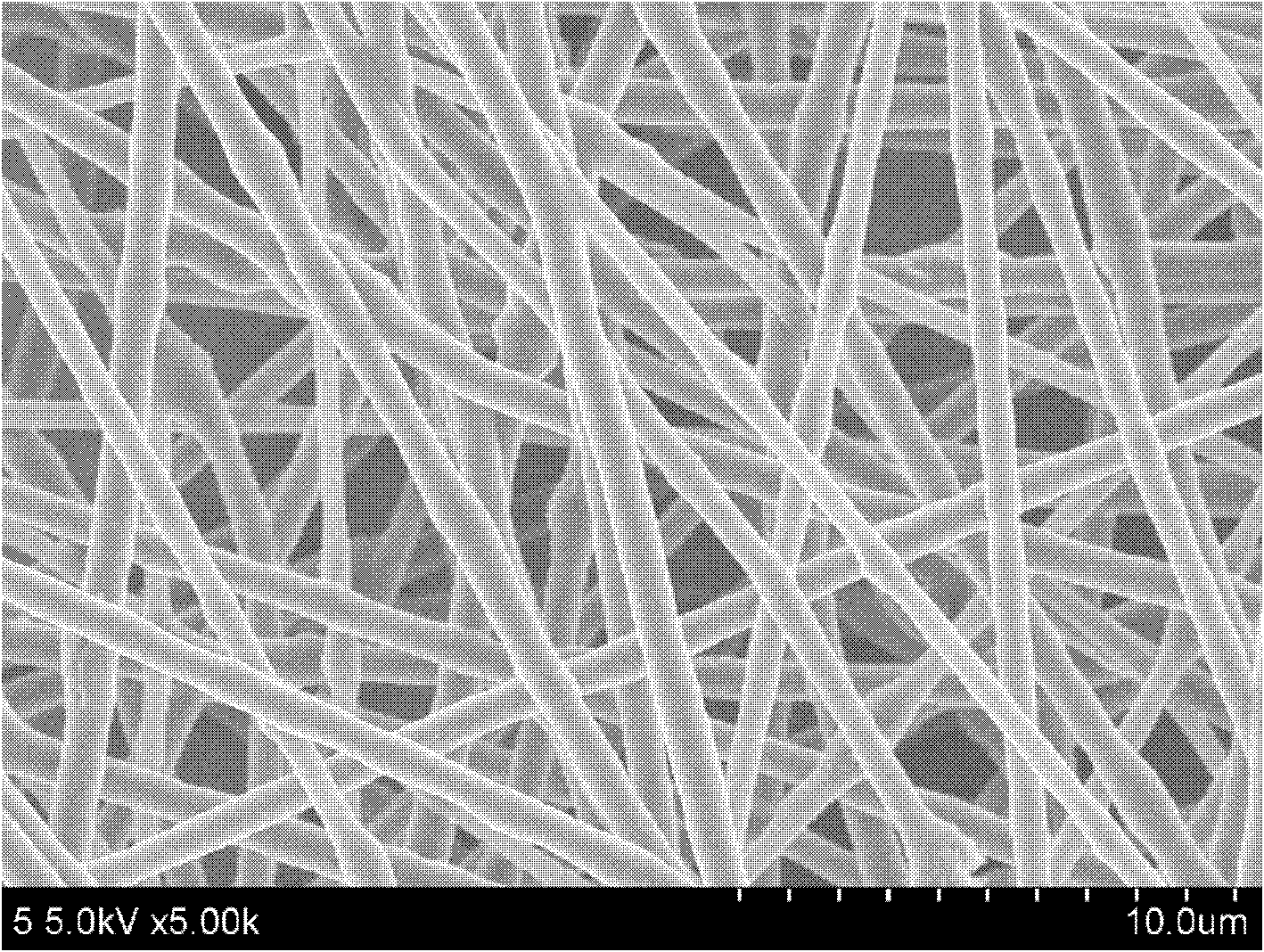

[0027] The cellulose nanocrystal dispersion liquid dispersed in N,N-dimethylformyl was slowly added to polyhydroxybutyrate valerate (number average molecular weight and molecular weight distribution were 4.5×10 4and 4.8) in the chloroform solution, wherein the total mass fraction of PHBV and CNCs in the mixed solution is 9wt%, the mass ratio of PHBV and CNCs is 99: 1, and the mass ratio of N,N-dimethylformamide and chloroform is 1:7.6; then the mixture was heated up to 70°C, fully stirred and swelled to obtain a transparent and uniform electrospinning stock solution; then the spinning solution prepared above was mixed in a needle tube with an inner diameter of 0.7mm and a flow rate of 1.8mL / h, Electrospinning was carried out under the spinning conditions of a voltage of 12kV and a receiving distance of 15cm, collected by a flat electrode, and the above product was vacuum-dried at room temperature for 24 hours to obtain PHBV / CNCs nanofibers or fiber membranes; the nanofibers wer...

Embodiment 2

[0029] The cellulose nanocrystal dispersion liquid dispersed in N,N-dimethylacetamide was slowly added to polyhydroxybutyrate valerate (number-average molecular weight and molecular weight distribution were 1.0×10 5 and 2.9) in the diethylene glycol dimethyl ether solution, wherein the total mass fraction of PHBV and CNCs in the mixed solution is 16wt%, and the mass ratio of PHBV and CNCs is 5: 1, N, N-dimethylacetamide The mass ratio of diethylene glycol dimethyl ether to diethylene glycol dimethyl ether is 1:9; then the mixed solution is heated up to 60°C, fully stirred and swollen to obtain a transparent and uniform electrospinning stock solution; Electrospinning was carried out under the spinning conditions of 0.7mm, flow rate of 1.5mL / h, voltage of 15kV and receiving distance of 18cm, collected by rotating drum, and the above product was vacuum dried at room temperature for 20h to obtain PHBV / CNCs nanofibers Or fiber film; the diameter of the nanofiber is 128nm obtained b...

Embodiment 3

[0031] The cellulose nanocrystal dispersion liquid dispersed in tetrahydrofuran was slowly added to polyhydroxybutyrate valerate (number average molecular weight and molecular weight distribution were 2.5×10 5 and 2.4) in the 1,2-chloroethane solution, wherein the total mass fraction of PHBV and CNCs in the mixed solution is 7wt%, the mass ratio of PHBV and CNCs is 49:1, tetrahydrofuran and 1,2-chloroethane The mass ratio of the mixed solution is 1:7.5; then the mixed solution is heated up to 58°C, fully stirred and swelled to obtain a transparent and uniform electrospinning stock solution; then the spinning solution prepared above is 0.7mm in the inner diameter of the needle tube and the flow rate is 1.0 Electrospinning was carried out under the spinning conditions of mL / h, voltage of 12kV and receiving distance of 14cm, collected by a rotating drum, and the above product was vacuum-dried at room temperature for 15h to obtain PHBV / CNCs nanofibers or fiber membranes; the nanofi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com