Drilling fluid additives and fracturing fluid additives containing cellulose nanofibers and/or nanocrystals

a technology of fracturing fluid and additives, which is applied in the field of nanocellulose, can solve the problems of fiber and particle damage, high energy consumption, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

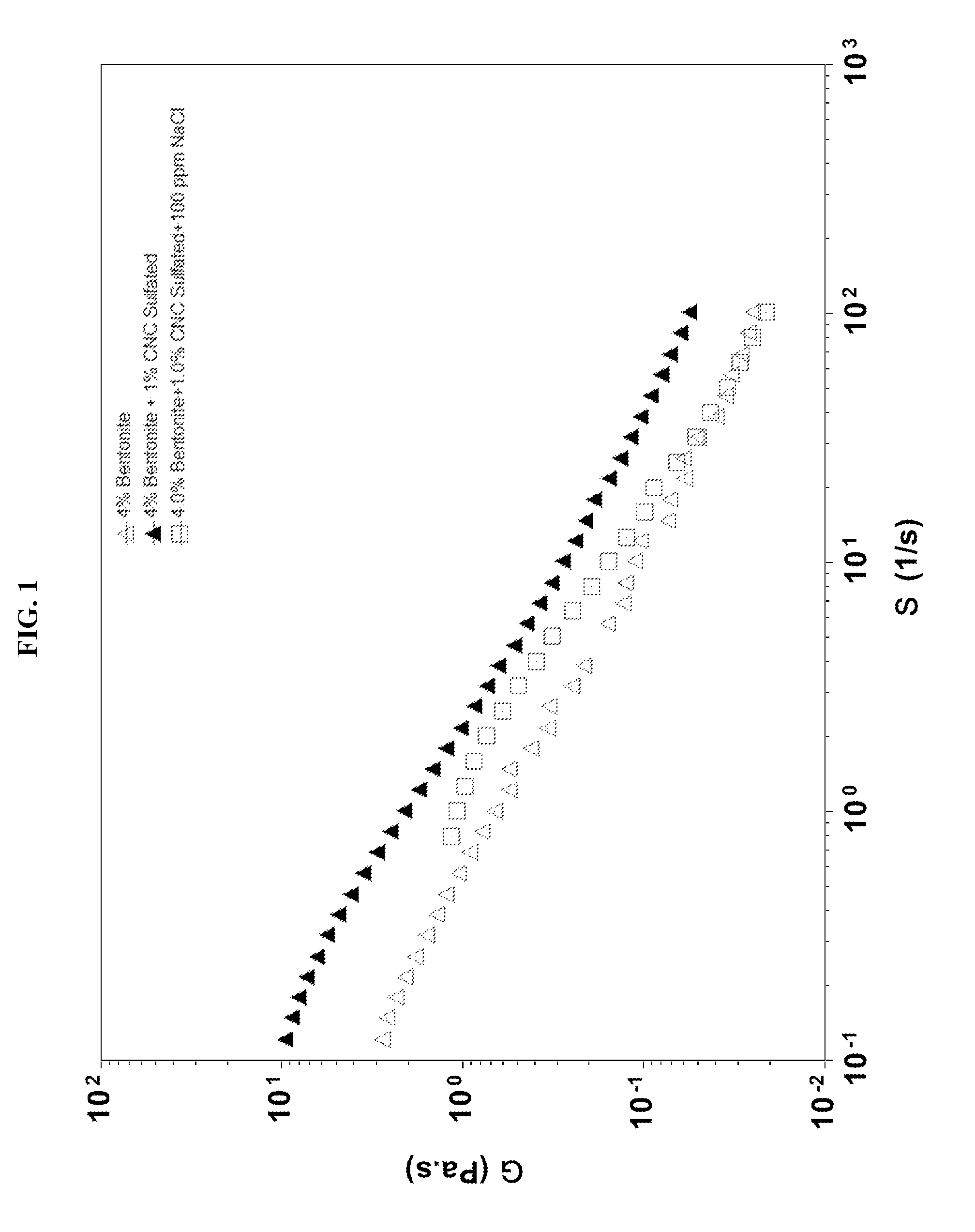

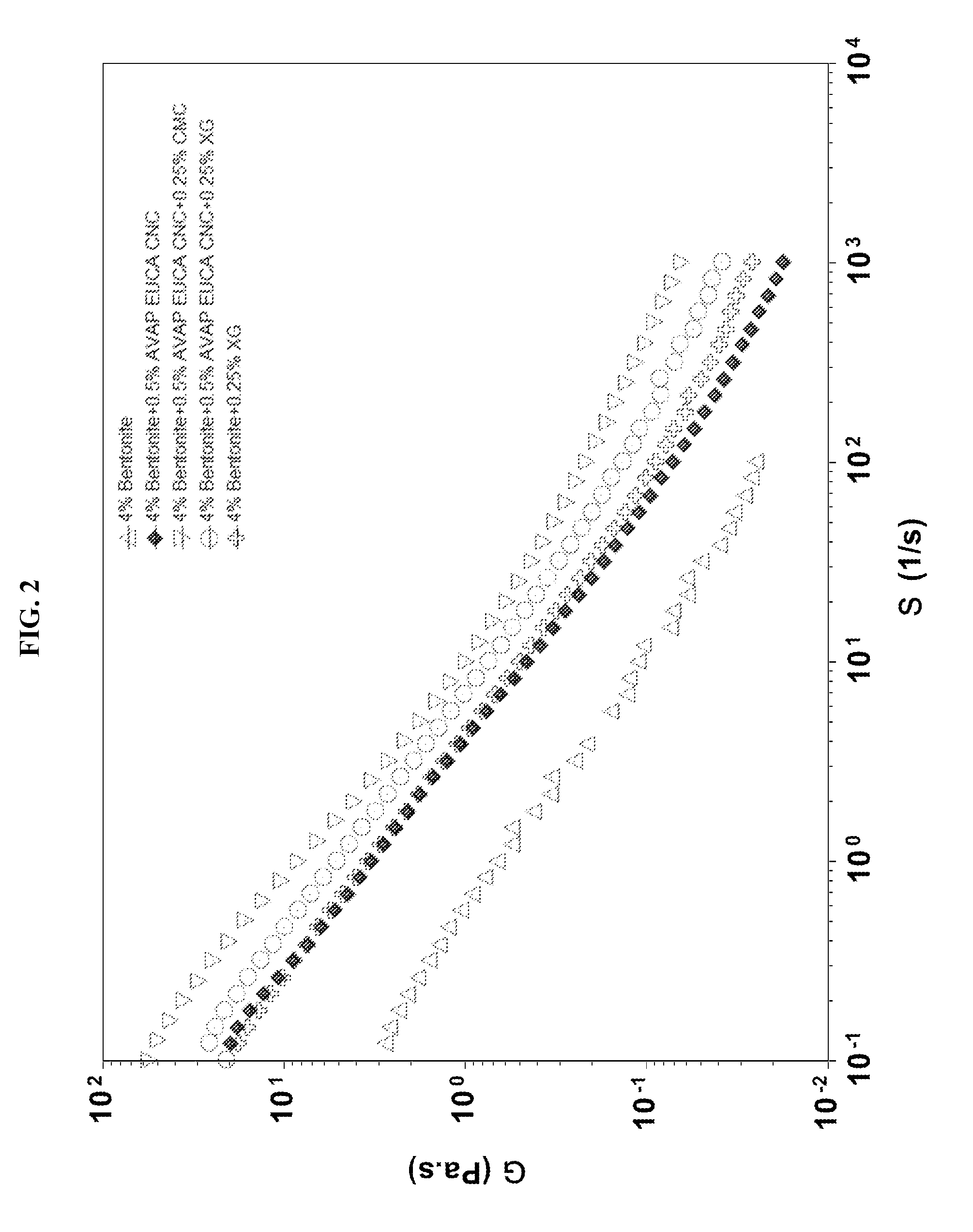

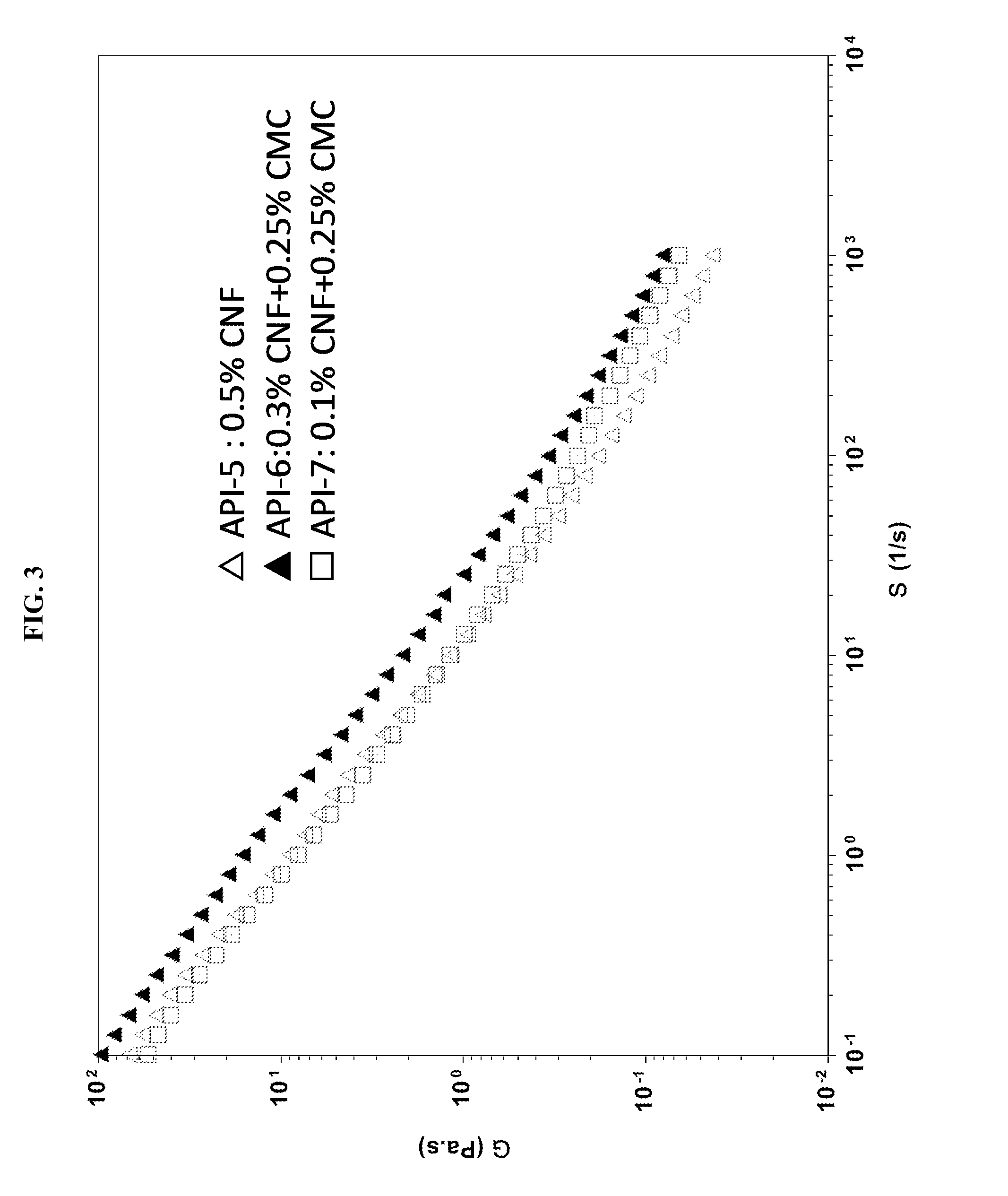

[0325]Colloidal suspensions are used in wide range of applications such as paints, coatings, cosmetics, ceramics, pharmaceutical formulations, food and household products. Addition of polymers to colloidal suspensions is a common practice to obtain the desired flow properties of such materials. Physical adsorption of polymers at the particle interface stabilizes or destabilizes colloidal suspensions. In addition, non-adsorbing polymers can also cause flocculation and / or phase separation. For the micron-size particles, polymer interactions have been studied extensively both experimentally and theoretically during the last three decades. While the nanoparticle-polymer mixtures are believed to start to play major roles in different fields, including drilling fluids and other oil field formulations, polymer-CNC and polymer-CNF interactions in aqueous solutions and their potential applications have not been exploited.

[0326]Drilling fluids have to meet multi-functional performance require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com