Preparation method of nanometer zinc oxide-bamboo charcoal composite particle with antibacterial and adsorption functions

A technology of nano-zinc oxide and composite particles, applied in chemical instruments and methods, botanical equipment and methods, nanotechnology for materials and surface science, etc., can solve the unutilized strong adsorption function, the combination of zinc oxide and bamboo charcoal particles Insufficient strength and other problems, to achieve the effect of shortening the preparation cycle, easy to adjust the size, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

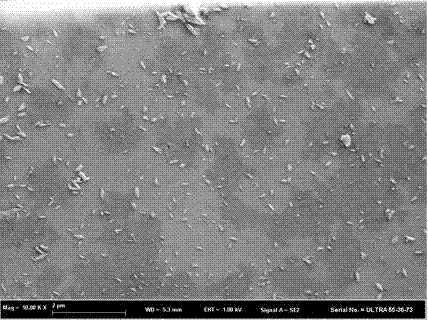

Image

Examples

Embodiment 1

[0024] Red shell bamboo was added to the mixed acid solution of oxalic acid and hydrochloric acid, wherein the solid-liquid ratio of red shell bamboo and mixed acid solution was 1:60 g / mL, and oxalic acid (4 mol / L) and hydrochloric acid (7 mol / L) with a volume ratio of 7:1, the mixed solution was reacted at 80°C for 14 hours, and after the reaction was completed, the reaction product was neutralized with sodium hydroxide to obtain carboxylated bamboo cellulose nanocrystals; the carboxylated The bamboo cellulose nanocrystal liquid added in the zinc chloride solution of 3mol / L, wherein the solid-liquid ratio of the bamboo cellulose nanocrystal of carboxylation and zinc chloride solution is 1:50 g / mL, with sodium hydroxide in proportion Neutralize, dilute the reaction product with deionized water, centrifuge several times to remove inorganic ions, then freeze-dry the dispersion, and then vacuum calcinate at 300°C for 4 hours to obtain nano-zinc oxide-bamboo charcoal composite part...

Embodiment 2

[0026] Add moso bamboo into the mixed acid solution of oxalic acid and sulfuric acid, the solid-liquid ratio of moso bamboo to the mixed acid solution is 1:40 g / mL, and the volume ratio of oxalic acid (3 mol / L) to sulfuric acid (10 mol / L) in the mixed acid solution is 8 : 1, the mixed solution was reacted at 85 ℃ for 10 h, and after the reaction was finished, the reaction product was neutralized with ammonia water to obtain carboxylated bamboo cellulose nanocrystals; adding 0.01mol of carboxylated bamboo cellulose nanocrystals / L of zinc sulfate solution, wherein the solid-liquid ratio of carboxylated bamboo cellulose nanocrystals and zinc sulfate solution is 1:100 g / mL, neutralize with ammonia water in proportion, dilute the reaction product with deionized water, and centrifuge several times Remove the inorganic ions, freeze-dry the dispersion, and then calcinate in vacuum at 400°C for 3 h to obtain nano-zinc oxide-bamboo charcoal composite particles. After the material is tes...

Embodiment 3

[0028] Add bamboo to the mixed acid solution of tartaric acid and sulfuric acid, where the solid-to-liquid ratio of bamboo to the mixed acid solution is 1:50 g / mL, and the volume ratio of tartaric acid (4mol / L) to sulfuric acid (9 mol / L) in the mixed acid solution 10:1, the mixed solution was reacted at 90 °C for 10 h, and after the reaction was completed, the reaction product was neutralized with potassium hydroxide to neutralize to obtain carboxylated bamboo cellulose nanocrystals; the carboxylated bamboo cellulose nanocrystals solution was added to 0.05mol / L zinc sulfate solution, wherein the solid-liquid ratio of carboxylated bamboo cellulose nanocrystals to zinc sulfate solution was 1:80 g / mL, neutralized with potassium hydroxide in proportion, and diluted with deionized water The reaction product was centrifuged several times to remove inorganic ions, then the dispersion was freeze-dried, and then vacuum-calcined at 500°C for 2 hours to obtain nano-zinc oxide-bamboo charc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com